Silicon Carbide

Reliable at highest stress

The first-choice material

for aggressive conditions

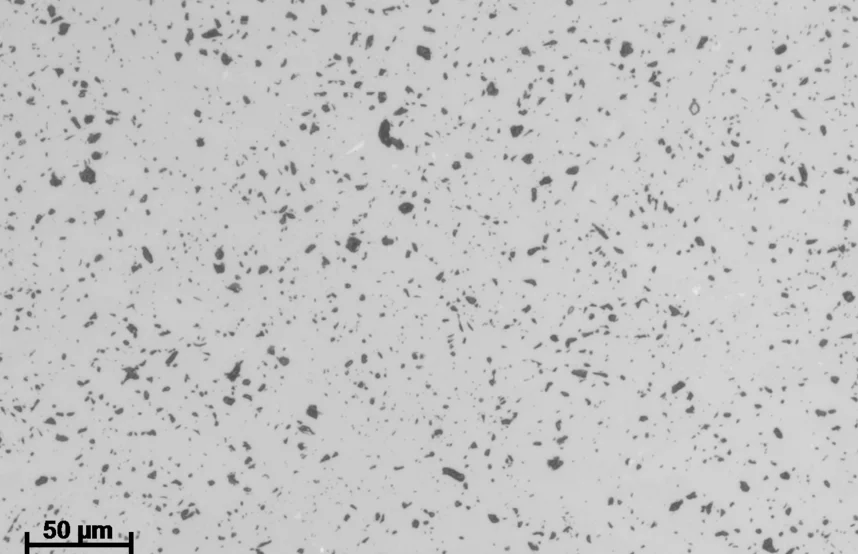

Whether in the petrochemical industry, chemical engineering, pump construction or shipbuilding, sliding rings, sliding bearings, pump impellers and other tribological components used in aggressive environments are permanently exposed to high stress What is needed here are materials that are resistant to external influences and function reliably. This is the perfect environment for our silicon carbide ceramics. As one of the lightest and at the same time hardest ceramic materials, silicon carbide shows its advantages wherever high corrosion and wear resistance is required and materials of safety-relevant components must not fatigue prematurely.

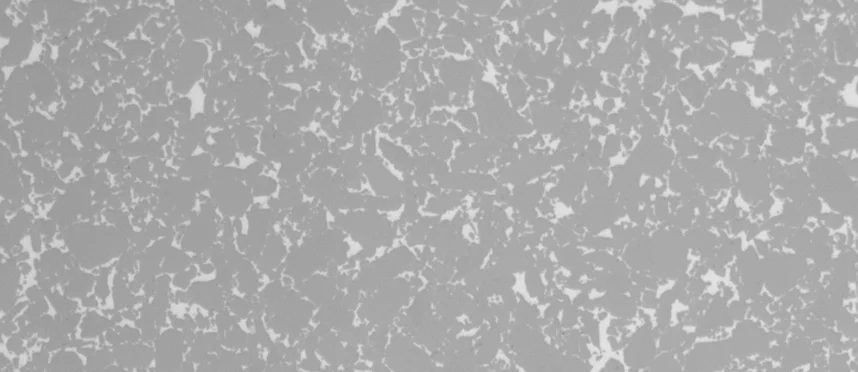

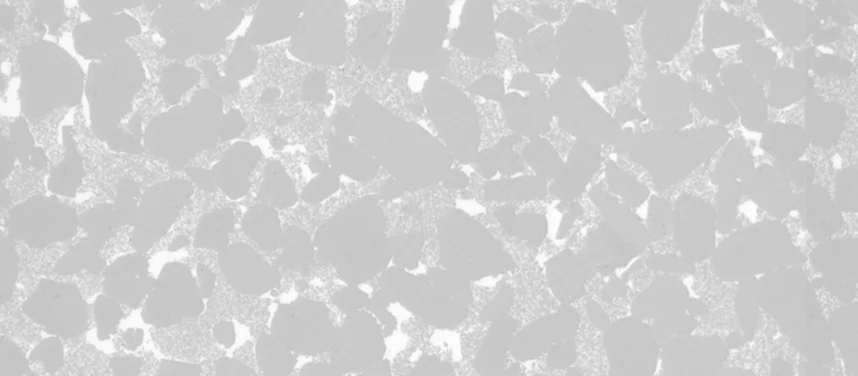

Silicon carbide differs depending on the manufacturing method and is therefore suitable for various applications. Depending on your requirements, we use reaction-bonded SiC, sintered SiC and - for geometrically complex products - 3D-printed IntrinSiC® to manufacture your components. Here, you can rely on the materials expertise and advice of our experts at Schunk Technical Ceramics.