Reliable Heat Treatment

for the Aerospace Industry - reliable materials and fixture systems

The advantages of Durafox® in high-temperature and oxidizing environments

Why Durafox® outperforms graphite and CFRC as an oxide fiber composite

- Significantly longer service life due to resistance to oxidation and corrosion

- High damage tolerance (ductile fracture behavior)

- Good thermomechanical properties

- Resistance to thermal shock and thermal cycling

- Distortion-free under thermocyclic stress enables quality improvement

- Low thermal conductivity

- Electrical insulator

- Lightweight construction (thin wall thicknesses can be realized)

- Metal-like, sheet-like designs possible

Brochure: Aerospace

Add

Brochure: Durafire® Dense

The solution for oil quenching

Add

Brochure: Wind Energy

Innovative Carbon Solutions for Onshore and Offshore Use

Add

Brochure: Glass Handling

Schunk Industry: Leading the Way in Glass Handling

Add

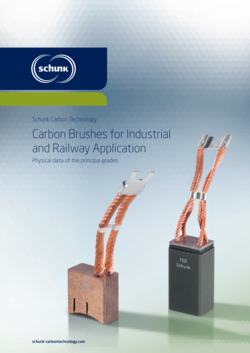

Physical Data: Carbon Brushes

for industrial and railway applications

Add

Recommendations: Carbon Brushes

for industrial and railway applications

Add

Brochure: Heat Treatment

Innovative Solutions for Thermal Applications

Add

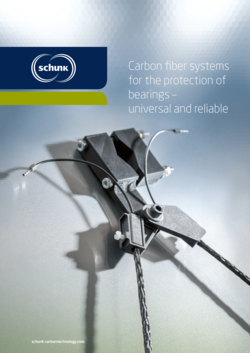

Brochure: Shaft Grounding

Carbon Fiber Systems for the Protection of Bearings - Universal & Reliable

Add

Standard Part List

Standard parts list in the field of high temperature applications

Add

Downloads

9 Files online