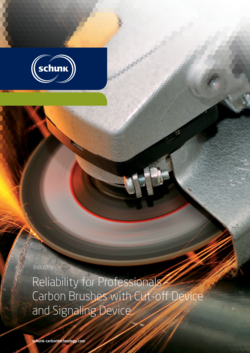

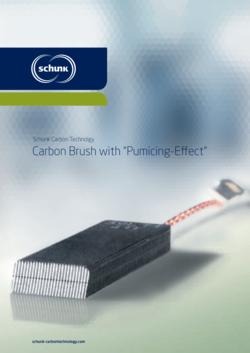

Our carbon brushes are well proven for use in all conditions. Even at high current densities, vibrations, dust generation, high speeds or weather conditions, they perform outstandingly thanks to above-average material quality. No wonder, since every solution incorporates our broad application engineering expertise and leading materials know-how. We supply you with materials tailored to your requirements with OEM approval or develop directly with you as an OEM. At Schunk, you can rely on a very high market presence through our companies in the most important markets and on a well-trained sales force. In addition, we are an established and financially strong company and are therefore in a position to carry out projects that require corresponding investments.

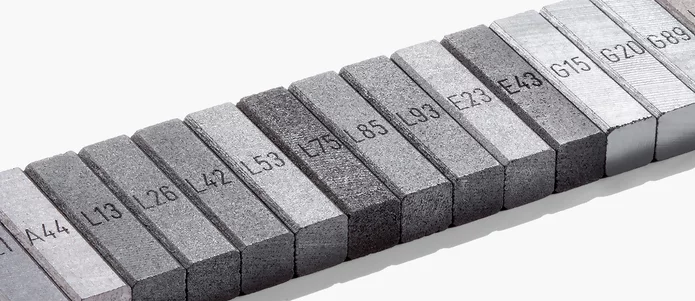

Consistent quality at the highest level

When it comes to our current transmission products, we know only one quality standard worldwide: the highest. You will not find any B-grades with us. After all, it is our claim to provide you with consistent quality at the highest level. Of course, this also applies to our customized materials for your specific application. Our carbon brushes, small contact strips, contacts for current transmission, brush holders and brush rockers have stood for safety, reliability, durability and efficiency for decades and after millions of applications worldwide.