Custom fixture systems for maximum energy efficiency

In many high-temperature applications, traditional cast grids are still used as fixture systems. However, they are increasingly reaching their limits, especially in terms of cost-efficiency and process stability. Schunk’s carbon fiber-reinforced carbon (CFC) fixtures set new standards: With advanced materials and customer-specific designs, they offer higher efficiency and improved process quality.

Custom fixture solutions for your heat treatment process

Our fixture systems serve as the foundation for your components during heat treatment. They directly influence quality, efficiency, and temperature uniformity. With decades of experience and deep material expertise, Schunk supports you from the initial concept to series production with customized fixture solutions tailored to your requirements.

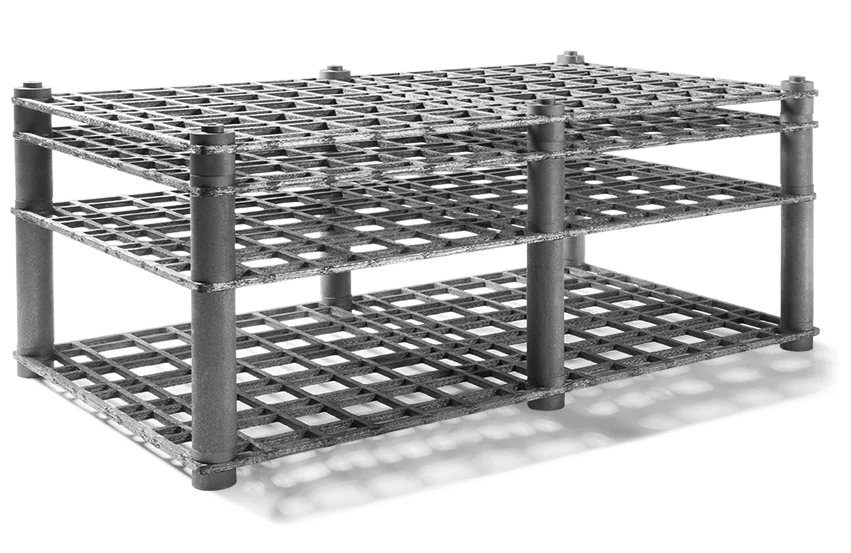

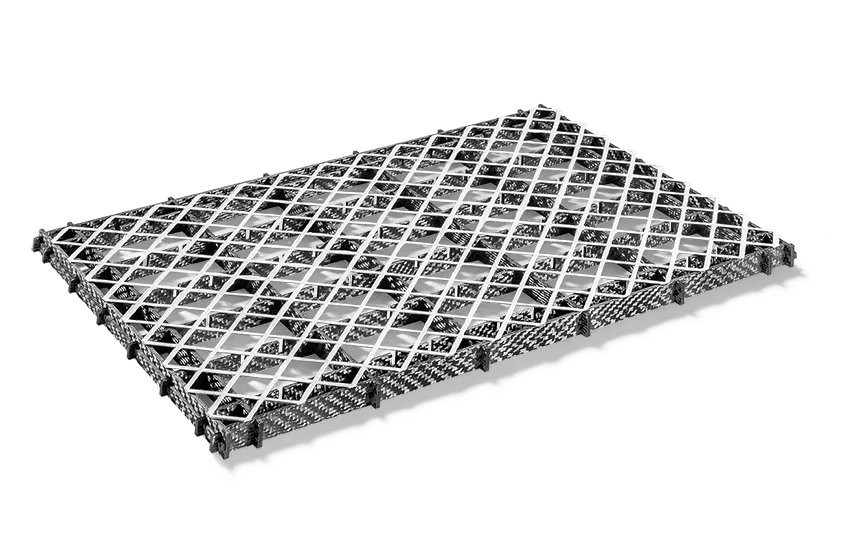

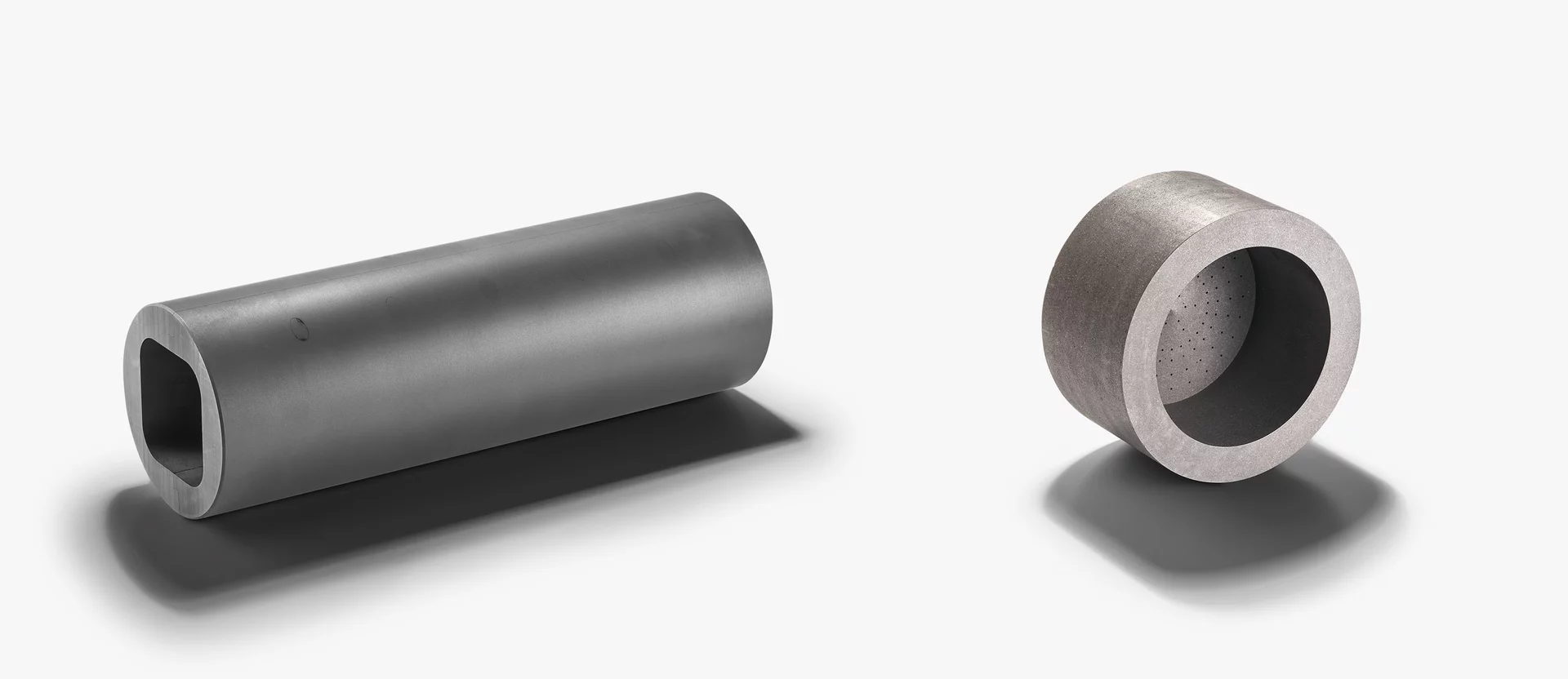

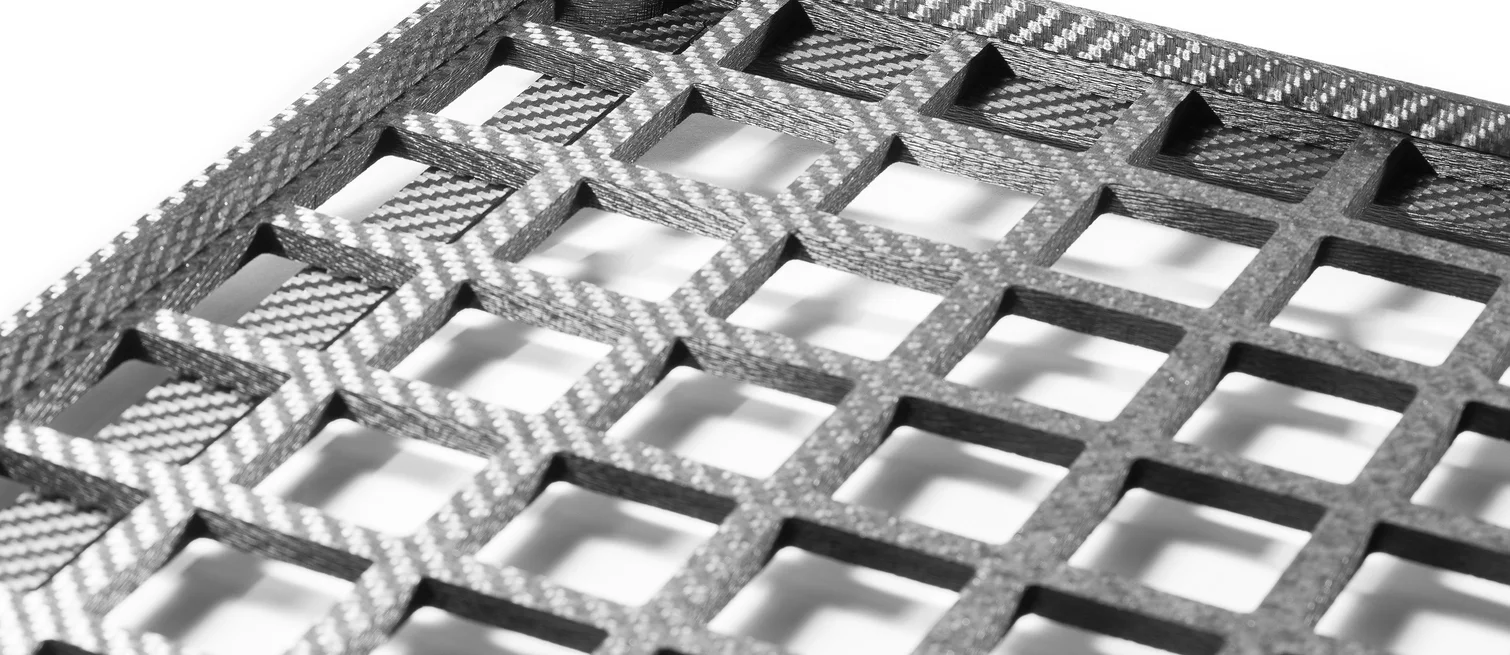

Assembled and water-jet cut CFC fixtures

Depending on the design, our CFC fixtures offer specific benefits:

-

Assembled CFC fixtures: Feature a flexible structure with adjustable rigidity – ideal for heavy loads.

-

Water-jet cut CFC fixtures: Designed for low to medium loads, enabling intricate geometries and cost-efficient production.

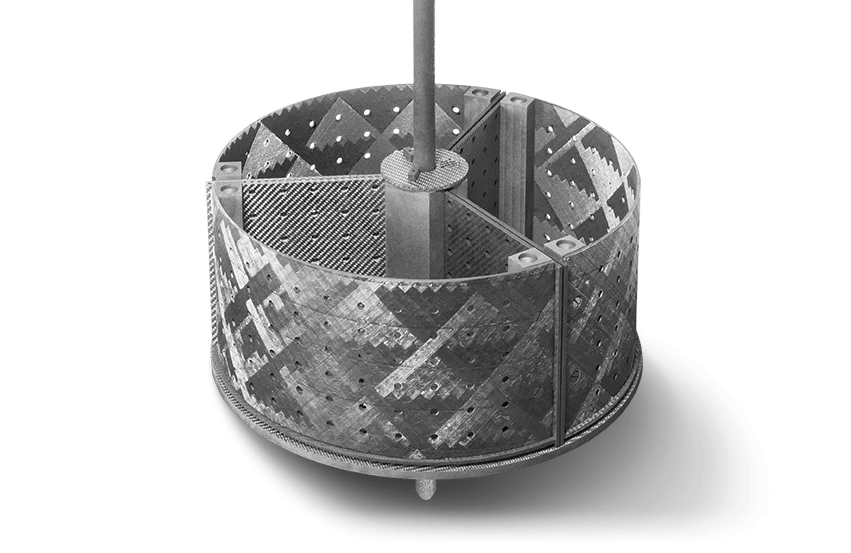

Barrier solutions for Enhanced Process Stability

Durafox® – thermal, chemical, and electrical barriers

Durafox® oxide ceramic composites offer reliable protection against thermal loads, corrosion, and carburization. Their advanced manufacturing ensures cost-effectiveness and durability. Operating at temperatures above 1,050 °C, they prevent material diffusion and unwanted reactions – enhancing process quality and safety.

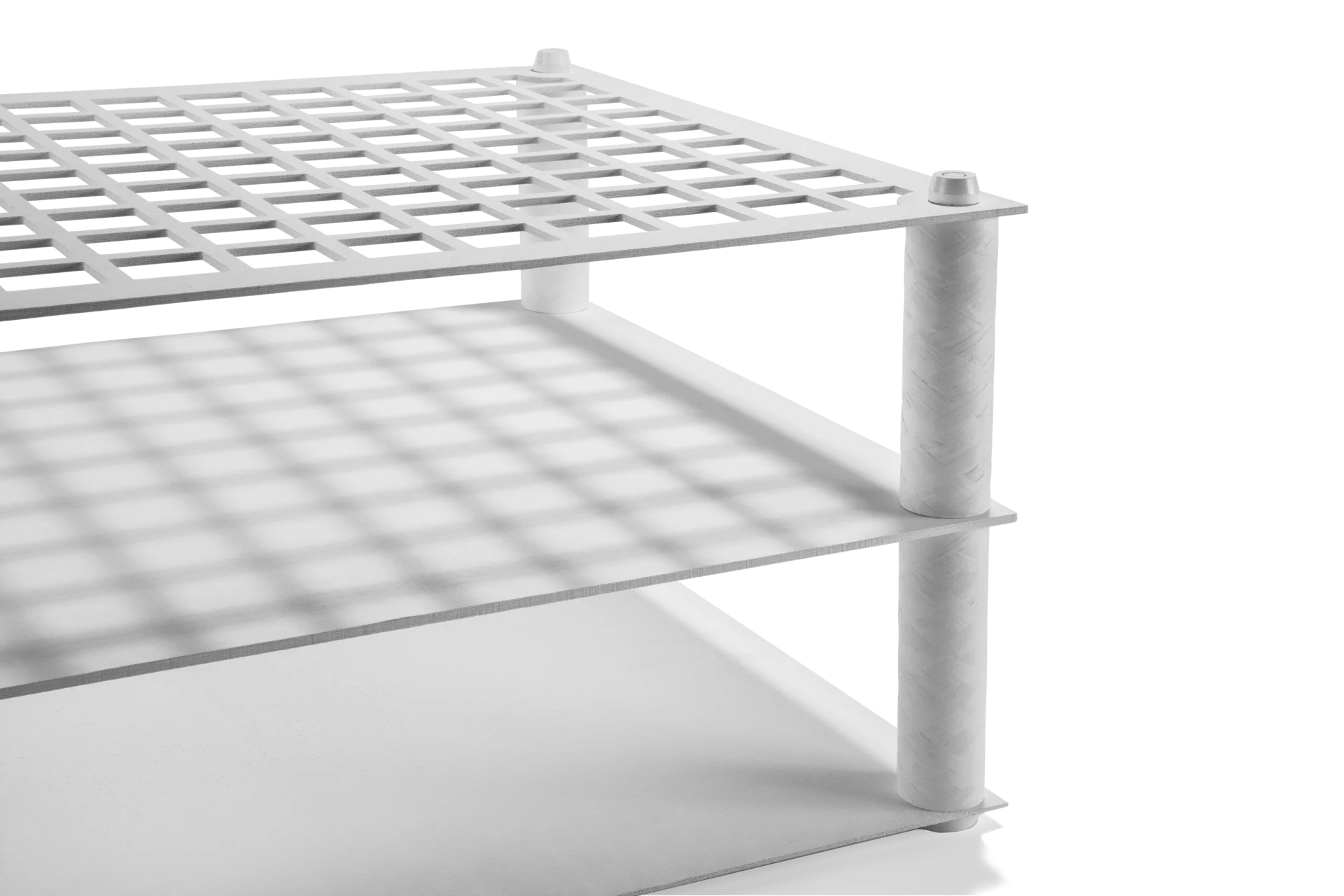

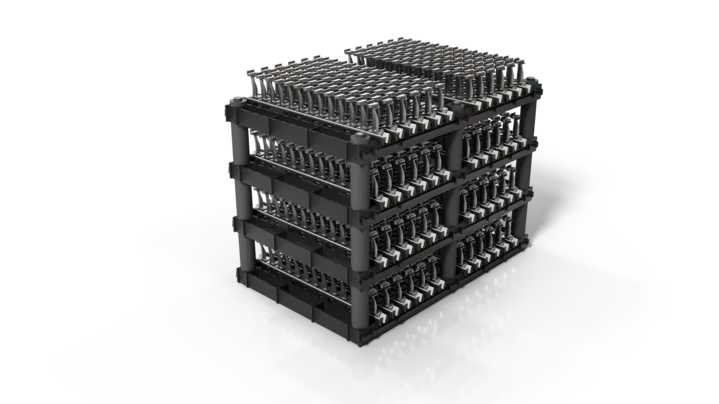

UniGrid® – the modular fixture system

UniGrid® is Schunk’s modular and standardized fixture solution. The integrally manufactured, joint-free structure offers exceptional stability and easy handling. Its modular design allows for flexible placement of graphite supports and efficient stacking – ensuring maximum flexibility and system integrity.

CarboGard® – protection against carburization

At temperatures above 1,050 °C, direct contact between load parts and UniGrid® may lead to carburization. CarboGard® ceramic inserts provide a lightweight, thermal shock-resistant solution for protecting parts from carbon uptake. Their seamless integration into the UniGrid® system allows flexible adaptation while minimizing thermal mass.

Advantages of CFC fixture systems

- High strength and distortion-free even under frequent thermal cycling

- Improved energy efficiency and lower operating costs

- Greater productivity thanks to increased furnace load and shorter cycle times

- More consistent hardening results across the load

- Option for automatic loading and unloading

- Reduced weight and lower thermal mass

- Long service life and minimal maintenance

Would you like expert advice? Our Product Manager for heat treatment will be happy to help you!

Tailored expertise for optimized results

Your fixture systems should be perfectly adapted to your process requirements. Our experts work closely with you to develop customized solutions using FEM analysis, special geometries, and complete documentation. With a global sales network and dedicated after-sales service, Schunk ensures end-to-end project support.

Initial consultation

Design proposal

Final agreement

Manufacturing

Delivery

After-sales-support

More than just hot – discover our entire range

Overview Heat Treatment

Innovative Solutions for Thermal Applications

Heat treatment with high-level know-how

Schunk Carbon Technology LLC

Schunk Carbon Technology LLC

The solution for oil quenching

Reliable Heat Treatment

for the Aerospace Industry - reliable materials and fixture systems

Downloads

Let us advise you

Do you have any questions about our carrier systems?