Advantages

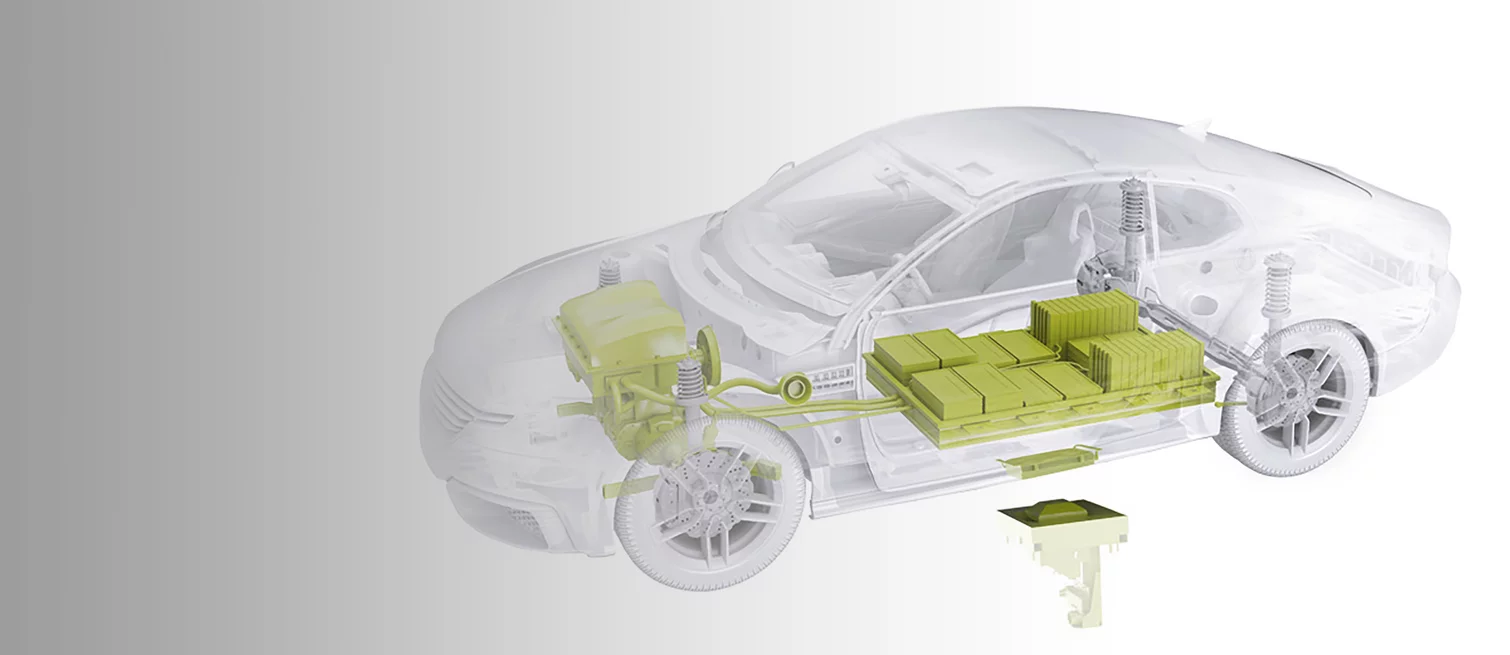

Innovative solutions for energy storage and supply

- Shorter charging times, thermal reliability and controlled thermal expansion

- Technologically leading materials of the highest quality

- Storage and recyclability of waste heat from combustion engines

- Reduction of cold start emissions by preheating engine oil and cooling water

- Buffering of temperature peaks

- Customised thermal properties

Schunk Group

Engineering competence in materials technology and machine building.

Add

Brochure: Material Selection Guide

Material selection guide for toolings: aluminium graphite

Add

Brochure: Driven by Imagination

Leading carbon technology for electrical, mechanical and thermal systems in cars

Add

Brochure: Latent Heat Carbon

Graphite-based thermal management systems for transformation, storage

and release of latent heat

Add

Brochure: Aluminium Graphite Composites

Thermal management materials for high reliability applications in power electronics

Add

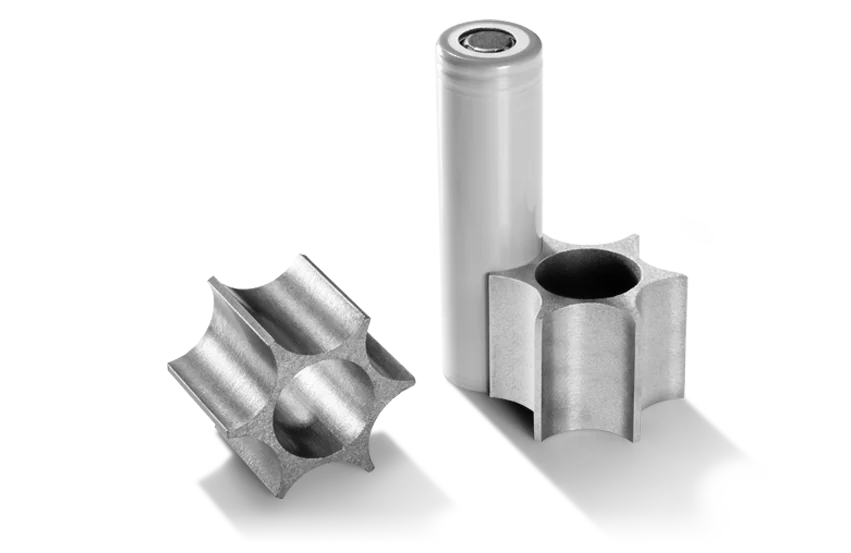

Brochure: Hybrid Parts: Sintermetal and Carbon

Imagine the possibilities

Add

Downloads

6 Files online