Advantages

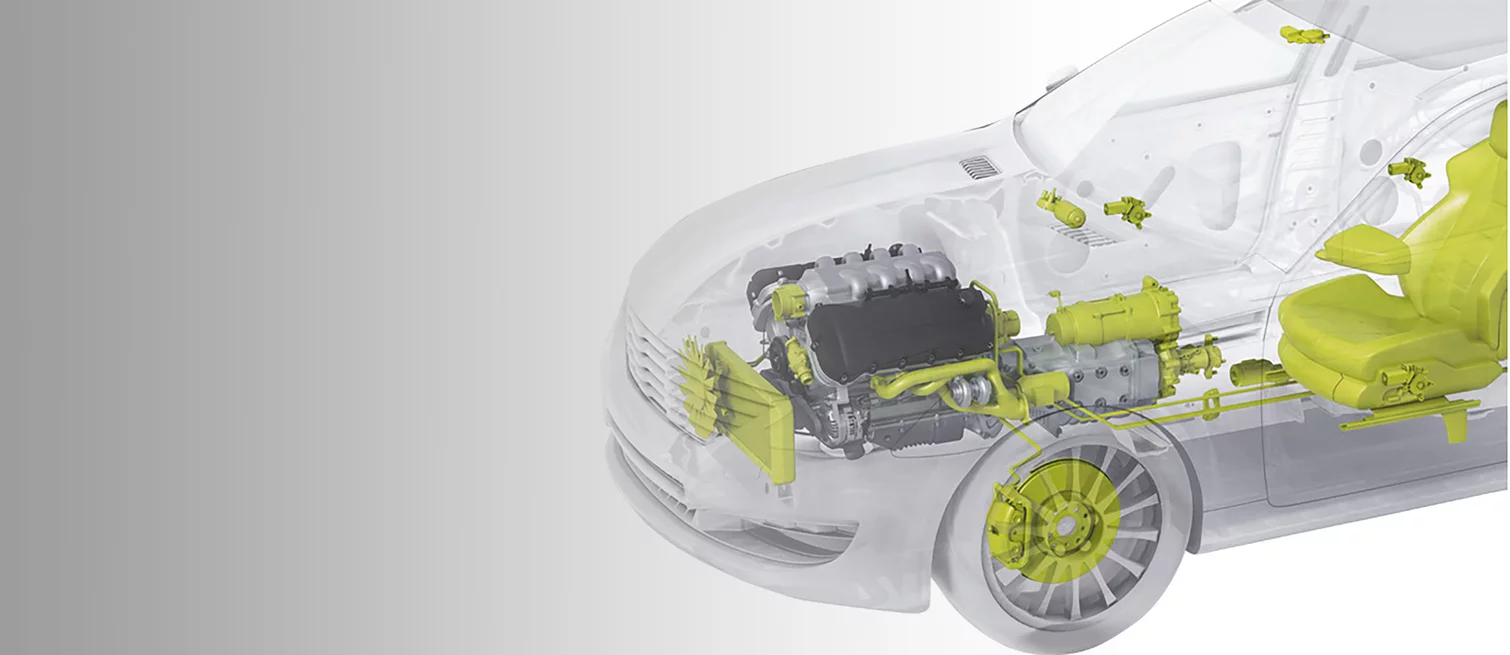

Pioneering solutions for the powertrain

- Carbon brushes with short development cycles and optimum product properties for customised applications

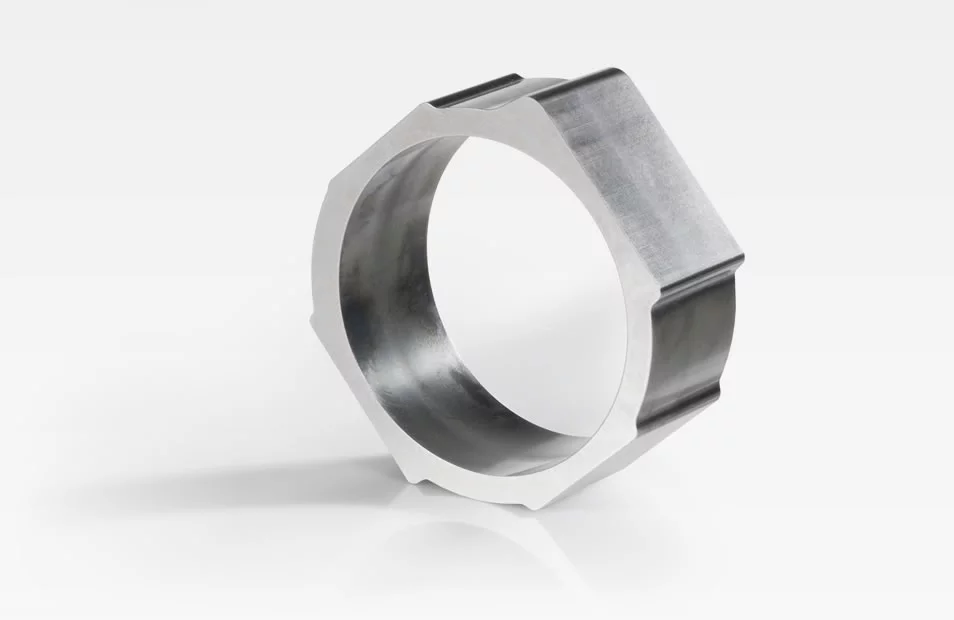

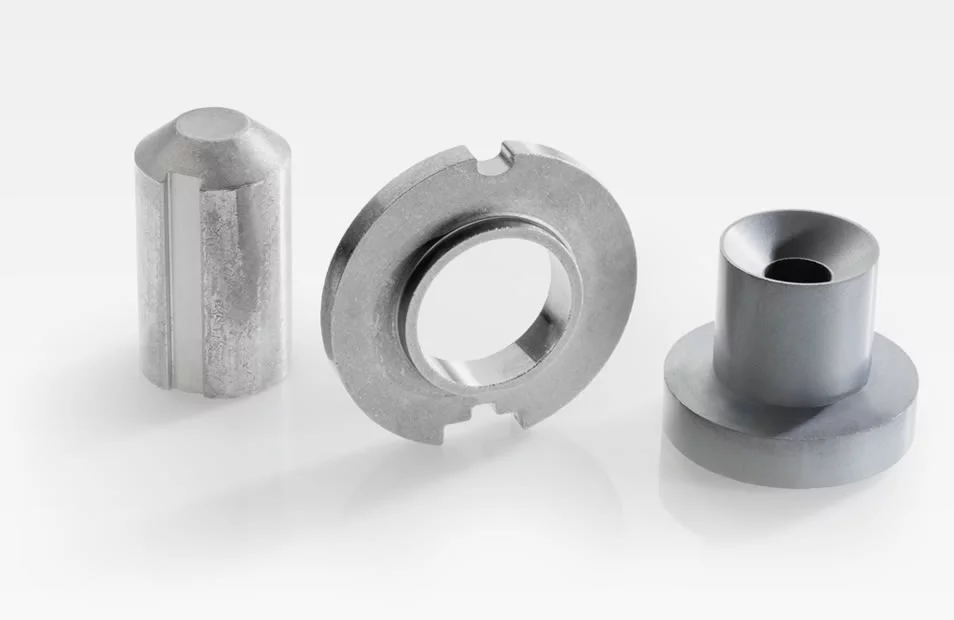

- Mechanical carbon components (MCA) with low weight, high precision, good tribological properties and high temperature and corrosion resistance

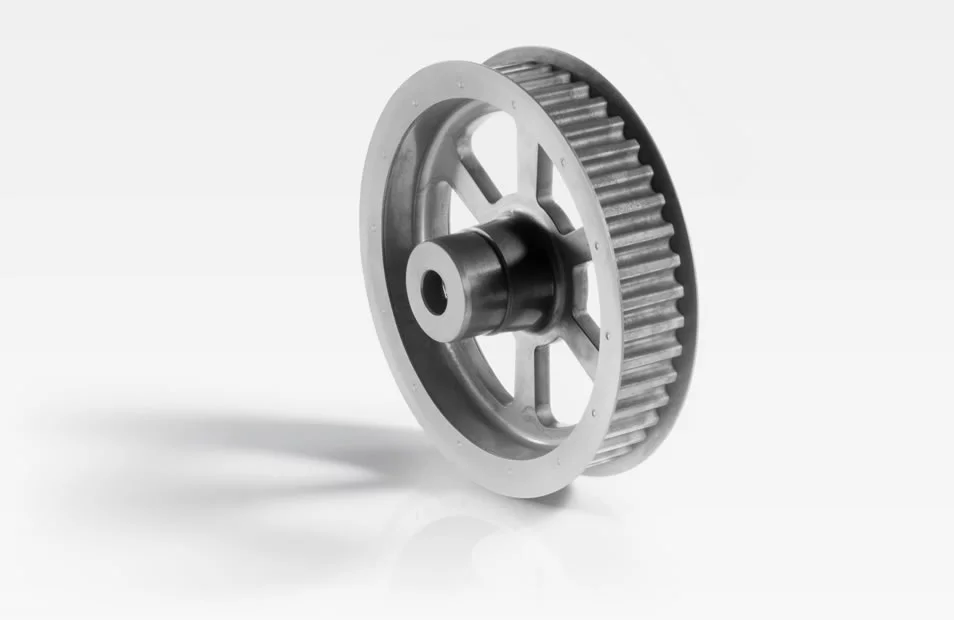

- Sintered components with cost savings compared to conventional manufacturing processes, reduced material requirements thanks to net shape design and high energy efficiency

- Standardised products in high volumes

- Everything from a single source - from customised development to all production processes

Schunk Group

Engineering competence in materials technology and machine building.

Add

Brochure: Material Selection Guide

Material selection guide for toolings: aluminium graphite

Add

Brochure: Driven by Imagination

Leading carbon technology for electrical, mechanical and thermal systems in cars

Add

Brochure: Injection Molded Components

As bearings in electric coolant-pumps

Add

Brochure: Shaft Grounding Contacts

Excellent bearing & RFI protection for future e-mobility

Add

Brochure: Hybrid Parts: Sintermetal and Carbon

Imagine the possibilities

Add

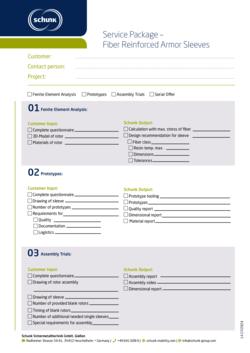

Service Package

Fiber Reinforced Armor Sleeves

Add

Brochure: Carbon-Graphite Rotor and Vanes

For rotary vane compressors and vacuum pumps

Add

Brochure: High Temperature Graphite Bearings

Dry lubrication for exhaust valves

Add

Downloads

9 Files online