Schunk Sintermetalltechnik Thale

Accredited testing laboratory “Friedrich Eisenkolb”

As an accredited testing laboratory with roots in the vision of Prof. Dr. Friedrich Eisenkolb, we combine scientific excellence with practical materials testing in Thale. Put your trust in an institution that has been embodying competence, precision, and commitment for more than six decades.

Information on the accreditation of our testing procedures

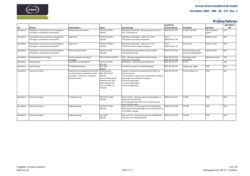

Our testing procedures are subject to the highest quality standards. Please note that not all procedures within the scope of our services are accredited. The accredited testing procedures are documented in the appendix to the accreditation.

This appendix is publicly accessible and can be viewed via the following sources:

Your partner for demanding material testing

Competent, fast, and flexible

The Friedrich Eisenkolb testing laboratory specializes in mechanical-technological and analytical testing procedures for metallic and powder metallurgical materials, as well as metal powders and technical cleanliness. With an experienced team, state-of-the-art equipment, and maximum flexibility, we are your reliable testing partner—fast, certified, and solution-oriented.

Our testing procedures

Mechanical and technological tests

Metallography

Powder testing

Technical cleanliness test

Physical tests

Non-destructive material testing

Chemical analyses

Scanning electron microscopy

Let us advise you

Contact us now – we will be happy to advise you personally on your testing project.