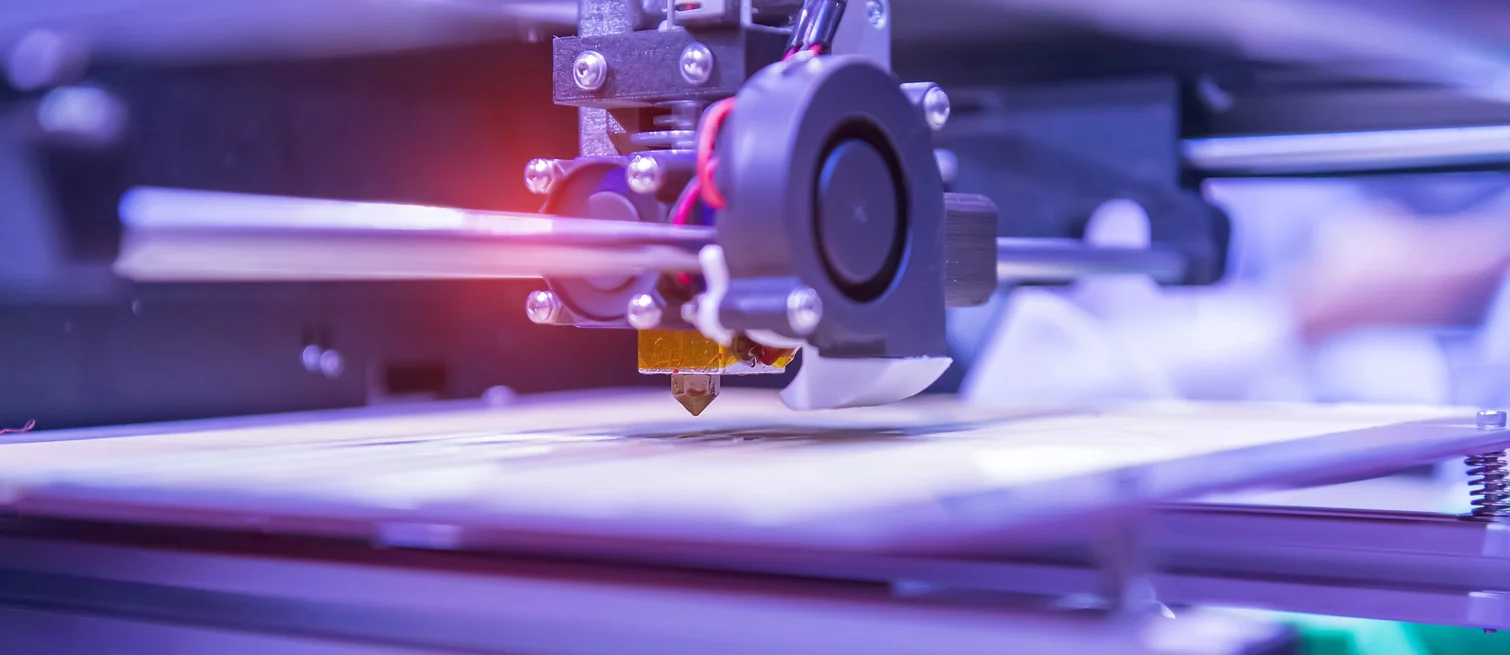

Limitless design freedom with toolless processes: Additive Manufacturing by Schunk

Advantages

Benefit from the advantages of our additive manufacturing

Benefit from our expertise in sintering and powder technology in the field of additive manufacturing. With us as a certified industry partner, you can rely on our constant adherence to high quality standards.

To enable us to translate our many years of experience into new developments and individual solutions for you even more quickly and comprehensively, we combine our four core competencies of materials expertise, design, material and process development, state-of-the-art shaping technologies and a comprehensive range of surface treatments into a kind of toolbox, from which we extract the best approaches and solutions for you. Among other things, this gives you the advantages of customer-focused work and efficient progress towards series production.

Videos

Creating Future. With carbon and ceramics.

Carbon fiber sheet molding compound

Dry lubrication for exhaust valves

As bearings in electric coolant-pumps

Graphite-based thermal management systems

For rotary vane compressors and vacuum pumps

Leading carbon technology for electrical, mechanical and thermal systems in cars

Excellent bearing & RFI protection for future e-mobility

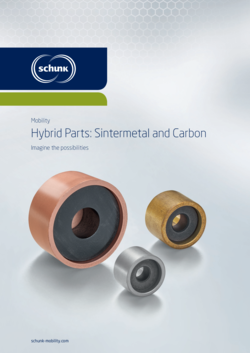

Imagine the possibilities