Advantages

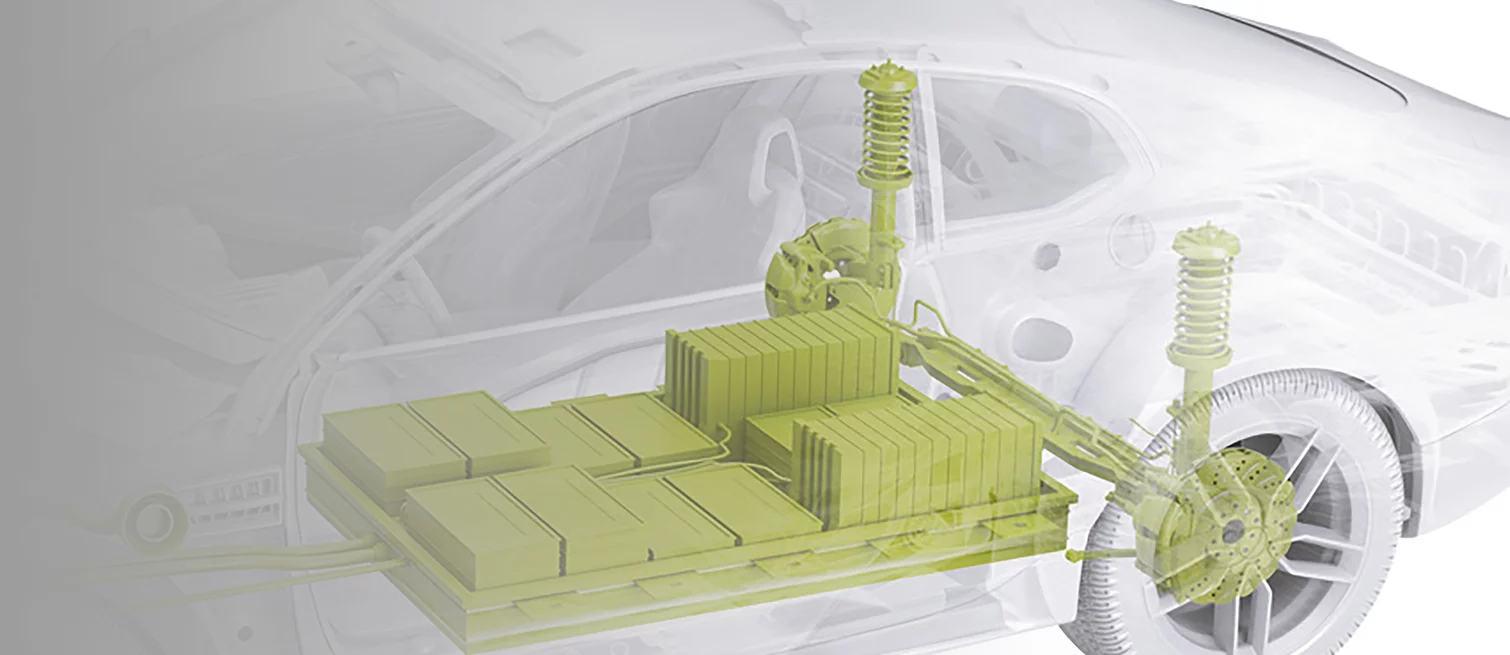

Innovative solutions for electric powertrains

- Shaft grounding: reliable protection for electric engines against high-frequency, parasitic shaft voltage draws

- Thermal management: customer-specific, lightweight materials that respond to thermal requirements

- Mechanical carbon components with low weight, high precision, good tribological properties, and excellent temperature and corrosion resistance

- Powder metallurgy as a standard process for stable, large-scale series production of soft magnetic components

- The greater design freedom offered by isotropic material properties allows for more complex engine topologies, such as axial and transverse flow engines

Schunk Group

Engineering competence in materials technology and machine building.

Add

Brochure: Material Selection Guide

Material selection guide for toolings: aluminium graphite

Add

Brochure: Driven by Imagination

Leading carbon technology for electrical, mechanical and thermal systems in cars

Add

Brochure: Shaft Grounding Contacts

Excellent bearing & RFI protection for future e-mobility

Add

Service Package

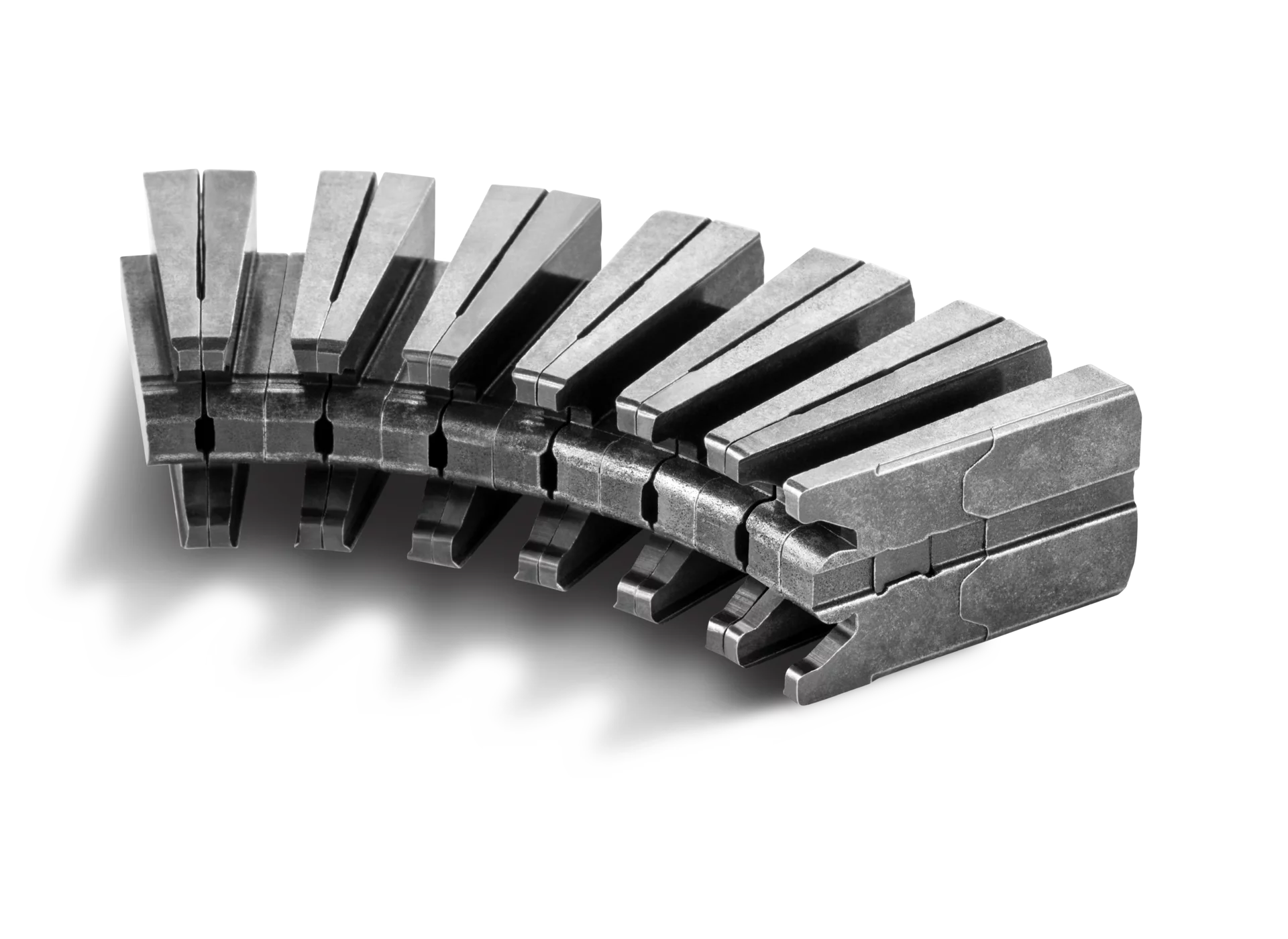

Fiber Reinforced Armor Sleeves

Add

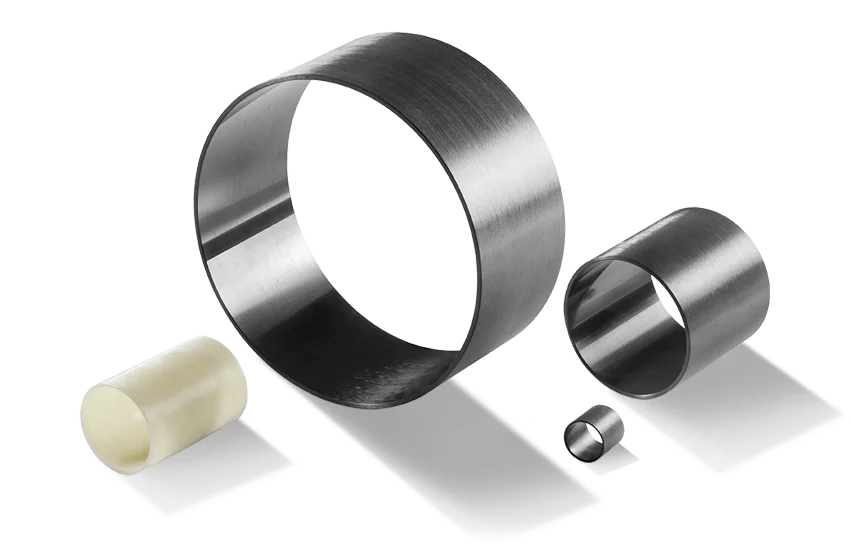

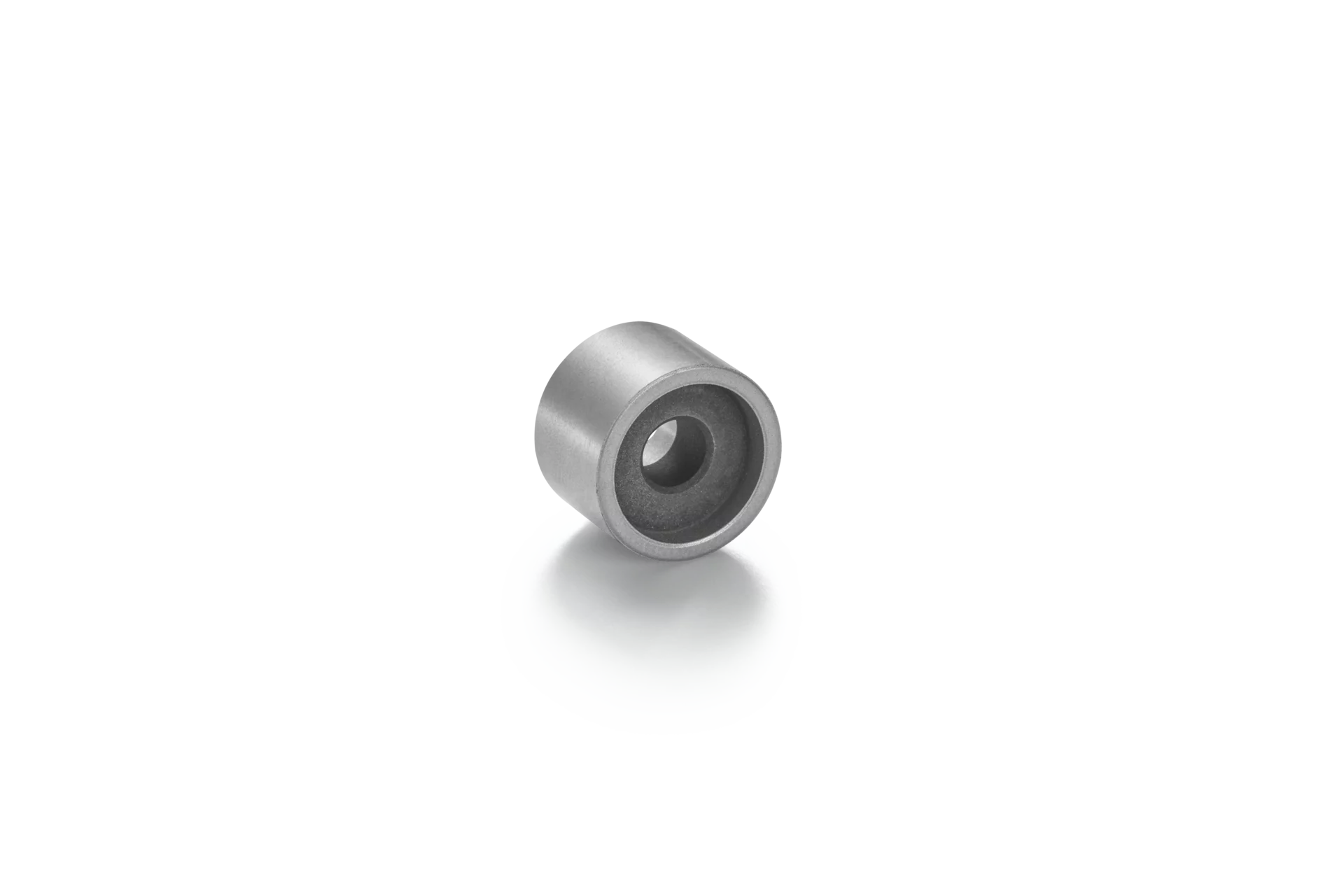

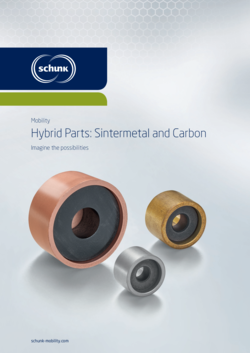

Brochure: Hybrid Parts: Sintermetal and Carbon

Imagine the possibilities

Add

Brochure: Injection Molded Components

As bearings in electric coolant-pumps

Add

Downloads

7 Files online