Would you like to get to know us and our solutions in person? Then visit us at international trade fairs and congresses. We look forward to see you!

Current datesChassis and Brakes

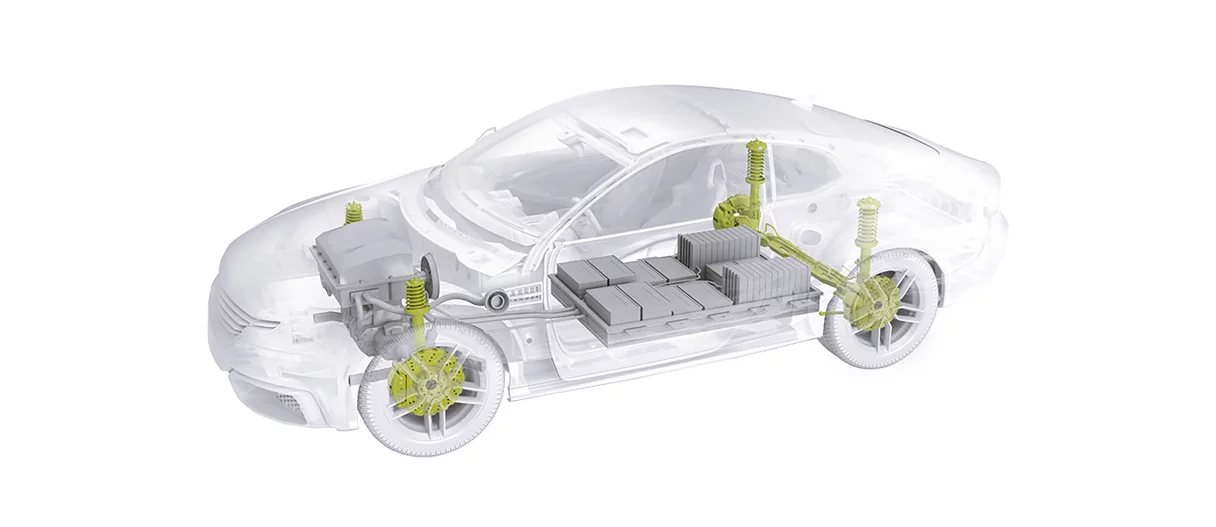

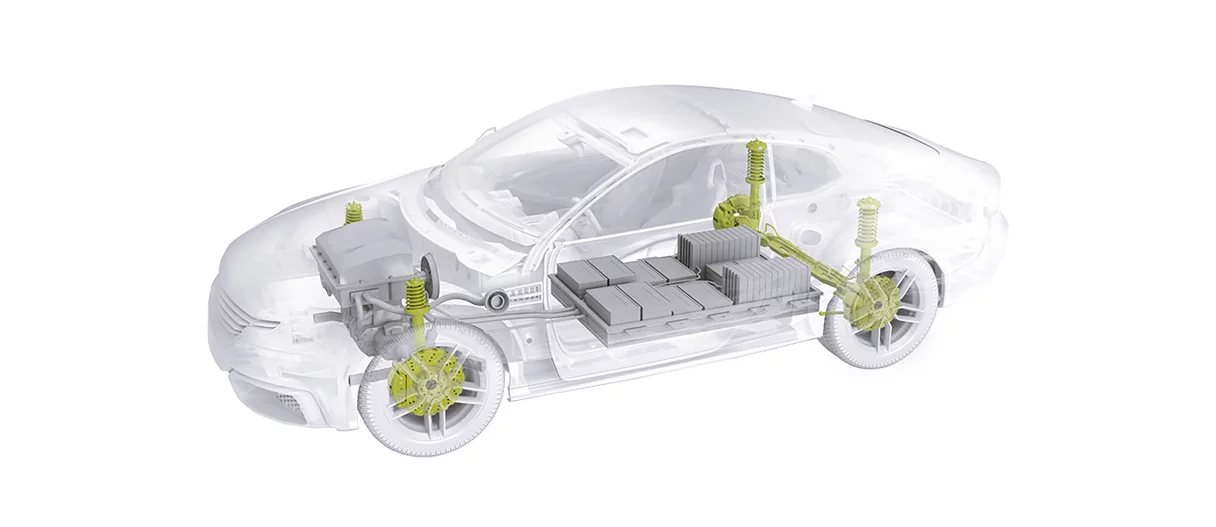

Overview of our components for body construction and brakes

Chassis and brakes – the highest safety demands the highest quality

Safety is an important topic in automotive construction, and safety requirements are always increasing. In this highly sensitive area, it is important to trust in outstanding quality, long-term expertise and proven innovative capacity. That is what Schunk Mobility offers. Our body construction and brake components impress through perfectly selected materials, individually optimized properties, and inexpensive production with the lowest error tolerances.

“Electrical Carbon” for reliable current transmission in automotive applications

Electrical components in modern motor vehicles are the driving force behind pioneering solutions for drive systems, driving safety and comfort. Innovative carbon products from Schunk are always on board. They fulfill the highest requirements for functionality, service life and temperature resistance. Our carbon brushes are used, for instance, in ABS motors in modern braking systems, and impress with their extremely short start-up time and reaction time, with significantly reduced noise production.

Mechanical carbon components for seamless processes in body construction and brakes

The requirements applied to tribological automotive components are always increasing, in order to improve their effectiveness and service life. Our materials are custom-tailored to your requirements, and are the ideal solution to these demands. We use these materials to manufacture rotors and vanes, for instance, for vacuum pumps in brake boosters.

Your reliable automotive development partner

When it comes to mobility requirements, our experts’ work starts from a single question: how can our solutions move you forward, as rapidly as possible? We employ all of our expertise to find the right answer to that question for you. From customized materials development to component design and prototyping, to series production and logistics – benefit from our ability to integrate our expertise early on in the process.

We handle all production processes in sintered technology

From components for electric parking brakes to components for electric tailgate drives or bearings for headlight cooling – our sintered components not only deliver innovative quality, but are also ready to install and economically efficient as well. This is made possible by our principle of offering you everything from a single source – this helps us keep all aspects of production and cost under control for you.

Do you have any questions about our Components for Body Construction and Brakes?