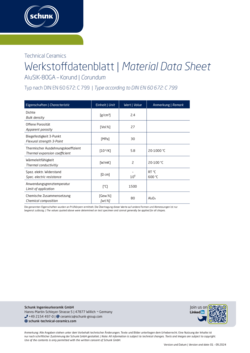

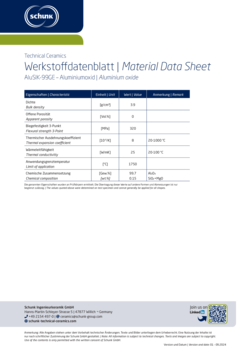

Material data sheet for AluSIK-80GA

High-Performance Ceramics by Schunk

Light, exceptionally hard, and capable of withstanding extreme temperatures, corrosive media, and abrasive wear - Schunk’s technical ceramics empower engineers with new design possibilities. Whether for a prototype or large-scale series — our materials and solutions are tailored to your needs, ensuring dependable performance across the entire lifetime.

What are Technical Ceramics

Technical ceramics, often referred to as high-performance ceramics or engineering ceramics, comprise a group of inorganic, non-metallic materials that have been specifically optimized for industrial applications. Unlike conventional ceramics, these materials are characterized by exceptional purity and special microstructures that make them indispensable for modern high technologies. They bridge the gap between abstract materials science and concrete industrial applications by performing where metals or plastics reach their physical limits. Their main characteristics are extreme hardness, enormous heat resistance, and excellent chemical resistance.

Go Directly to our Technical Ceramics Materials

Ultra-hard composite with excellent thermal shock resistance and near-zero wear—ideal for mechanical seals, turbines, and high-temperature components.

One of the hardest known materials, combining low density and extreme abrasion resistance—perfect for ballistic protection, slurry nozzles, and wear linings.

Cost-efficient and electrically insulating up to ~1,700 °C, with excellent chemical stability—widely used for insulating components, bearings, and precision ceramics.

Transformation-toughened with high flexural strength and low thermal conductivity—used in medical implants, precision valves, and wear parts.

Why Choose Schunk Technical Ceramics?

For more than a century, Schunk has pioneered advanced ceramic solutions for the most demanding environments. From concept to series production, we deliver all stages—material development, application engineering, manufacturing, and quality assurance—from a single source. Your benefits: shorter time to market, optimized total cost of ownership, and secure supply chain continuity.

Industries & Applications

Our high-performance ceramics are the key to advanced solutions in numerous industrial sectors.

Here you will find tailor-made concepts for your industry:

Ensure reliable long-term use and maximum precision in your systems thanks to extreme wear resistance.

Development of high-strength, ceramic protective armor made of boron carbide for maximum safety in extreme scenarios.

Benefit from high lightness and extreme heat resistance for components in satellite technology and space missions.

Optimize your thermal processes with heat-resistant burner components for significantly higher energy efficiency.

Increase your production efficiency with robust components specially developed for high-temperature applications.

Take advantage of the dimensional stability and chemical inertness of technical ceramics for high-precision measurement results in demanding environments.

Reliable performance at extreme temperatures and under chemical stress thanks to corrosion-resistant high-performance ceramics.

Maximum service life for sandblasting nozzles thanks to materials with maximum abrasion resistance, such as boron carbide.

Secure your processes with chemically resistant components that seal reliably even in aggressive media.

Your Advantages at a Glance

- Up to 70 % weight savings vs. steel

- Up to 10× better wear resistance, leading to longer service life

- Excellent corrosion resistance

- Dielectric properties into the GHz range

- Lower maintenance — reduced operating costs

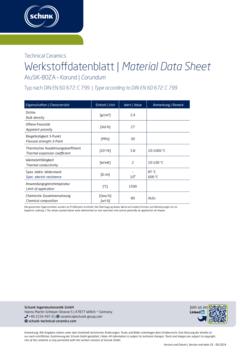

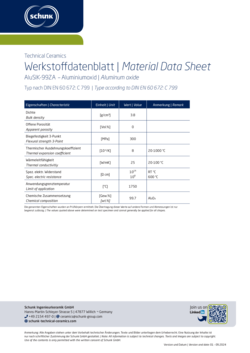

Material data sheet for AluSIK-80ZA

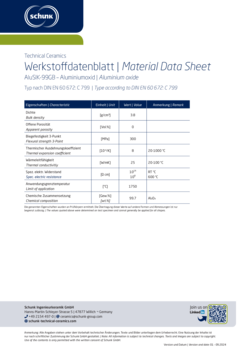

Material data sheet for AluSIK-99GB

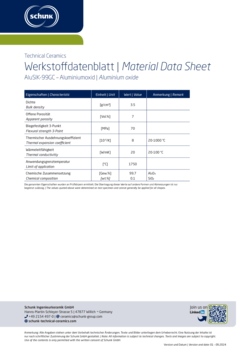

Material data sheet for AluSIK-99GC

Material data sheet for AluSIK-99GE

Material data sheet for AluSIK-99GG

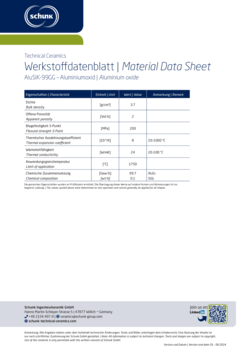

Material data sheet for AluSIK-99ZA

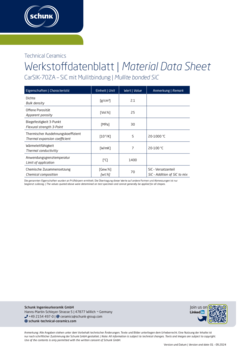

Material data sheet for CarSIK-70ZA

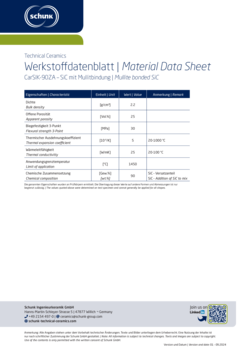

Material Data Sheet for CarSIK-90ZA

Downloads

Let us advise you

Do you have questions about our wide range of technical ceramic materials?