First Silicon Carbide Industrial 3D Printing Provider in Volume Production

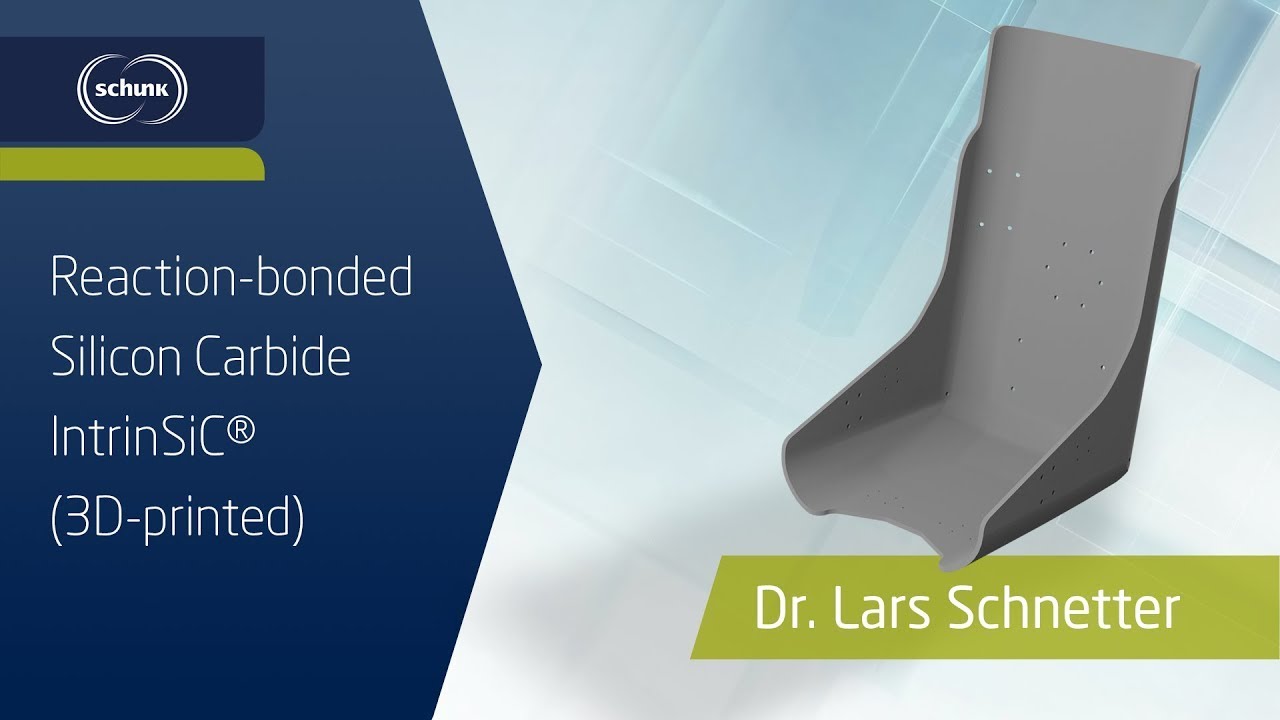

3D printing processes can be used to produce components from silicon carbide (BSiCR), marketed as IntrinSiC®. In doing so, Schunk has succeeded in raising the material properties of IntrinSiC® to the well-known level of conventional RB-SiC from Schunk. In addition to very good thermal shock resistance and thermal conductivity, IntrinSiC® is characterized by very high strength values, high reliability (high Weibull modulus), high oxidation, and corrosion resistance. Compared to other materials such as steel, the almost diamond-hard but lightweight ceramic offers extreme dimensional stability with a very low coefficient of thermal expansion. Compared to similar processes, 3D printing can produce significantly more complex and larger monolithic components (up to a size of 1.8 m x 1.0 m x 0.7 m). The new manufacturing process is particularly interesting for manufacturers who do not want to forego the usual high strength and reliability of RB-SiC for large, complex components. IntrinSiC® offers the globally unique possibility of producing 3D-printed RB-SiC consistent with material produced by conventional manufacturing processes. IntrinSiC® therefore provides customers from a wide range of industries with completely new possibilities, for example, in industrial precision and metrology. The high level of homogeneity also guarantees no impairment due to cracks in these extremely large components.

Process of additive manufacturing with silicon carbide

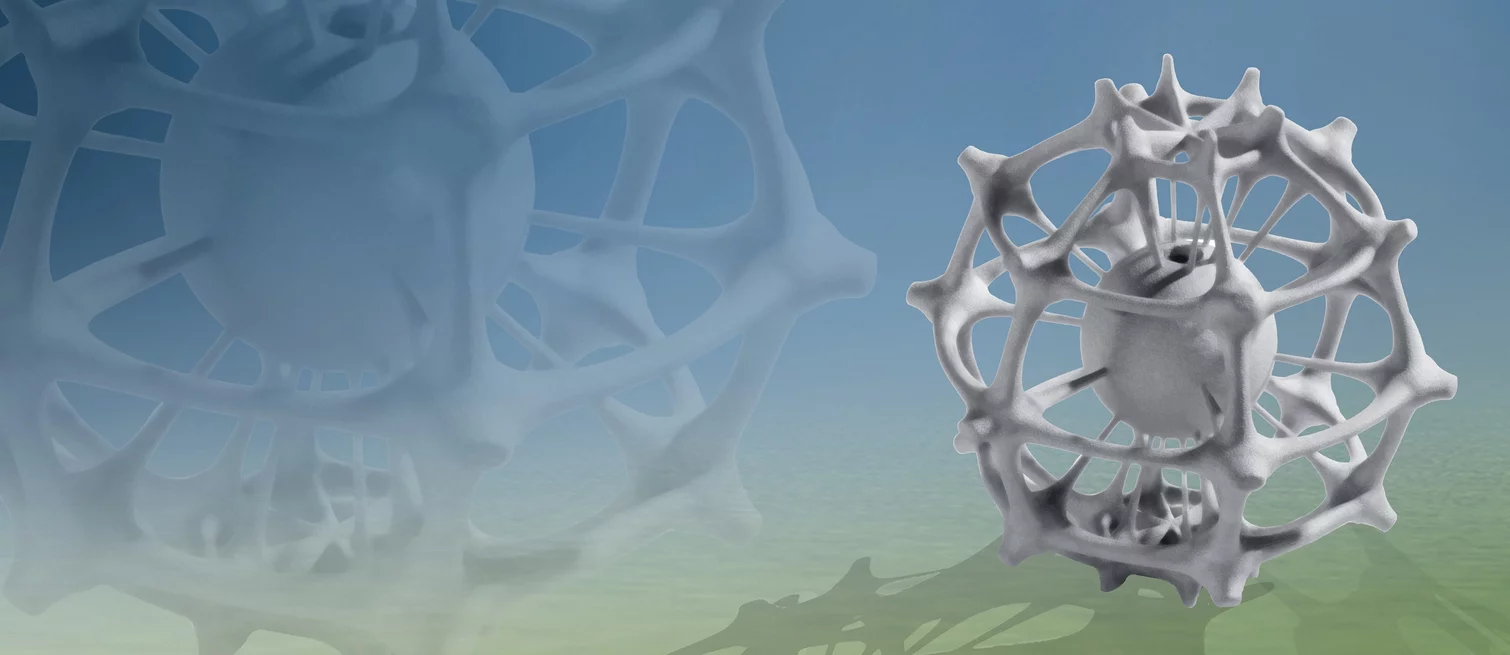

The IntrinSiC® 3D printing process is a powder bed printing process. In this process, the print data of a 3D model is broken down into individual 2D layers. A moving print head applies the binder to a powder layer, causing individual particles to bond. After the application of another powder layer, these sequences are repeated and the 3D object is successively built up.

Competitive advantages through innovation

As a first mover in this sector, Schunk also offers its expert knowledge as a service. We support our customers in the constructive design of components using FEM (Finite Element Method), Design-for-Manufacturing as well as topology optimization in order to improve reliability, weight savings, and mechanical structural properties. Optimized components can be manufactured immediately thanks to the CAD data, which enables short production lead and delivery times.