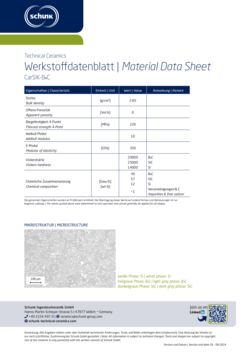

Material Data Sheet for CarSIK-B4C

Boron Carbide

Boron carbide is a non-oxide ceramic characterized by a particularly high hardness, a high modulus of elasticity and good wear resistance at low weight. The reaction-bonded RBB4C (at Schunk CarSIK-B4C) is used in particular in the ballistics sector. The ceramic combines exceptionally high hardness with low density and is thus optimally suited for lightweight solutions in personal protection and for lining land and air vehicles.

Boron Carbide

What distinguishes CarSIK-B4C?

CarSIK-B4C, which was specially developed at Schunk for ballistic protection, is a mixed quality of RBSiC and RBB4C and is optimized for the various ballistic threat classes. In Schunk's CarSIK-B4C, boron carbide particles are embedded in a silicon carbide matrix. The unique, patented structure gives the material an exceptional degree of hardness and ballistic protection to break and erode even hard core projectiles made of steel or tungsten carbide.

Where is CarSIK-B4C used?

As an overall composite with suitable fiber backing, CarSIK-B4C exhibits high impact resistance, which gives the protective plates high durability. In the defense & ballistics industry, boron carbide is unrivaled and irreplaceable. For the efficient production of close-tolerance, dimensionally accurate components made of boron carbide, Schunk Ceramics relies on modern and flexible manufacturing processes. In this way, die casting or isostatic pressing are used to create excellent products at a consistently high, reproducible quality level for prototype and series production. This consistency in geometry and material properties is appreciated by our customers worldwide. More than 1,000,000 plates supplied speak for themselves.

Special features

of CarSIK-B4C

- Hardness: 25 GPa

- Density: 2,85 g/cm³

- Compressive strength: 2900 MPa

- Thermal conductivity: W/mK

- Flexural strength: 220 MPa

- Modulus of elasticity: 350 GPa

3D printed boron carbide IntrinSiC B4C

From the first mover and 3D market leader in non-oxide ceramics.

Soon available. Contact us for samples.

SiC & B4C armour materials for ballistic protection