Advantages

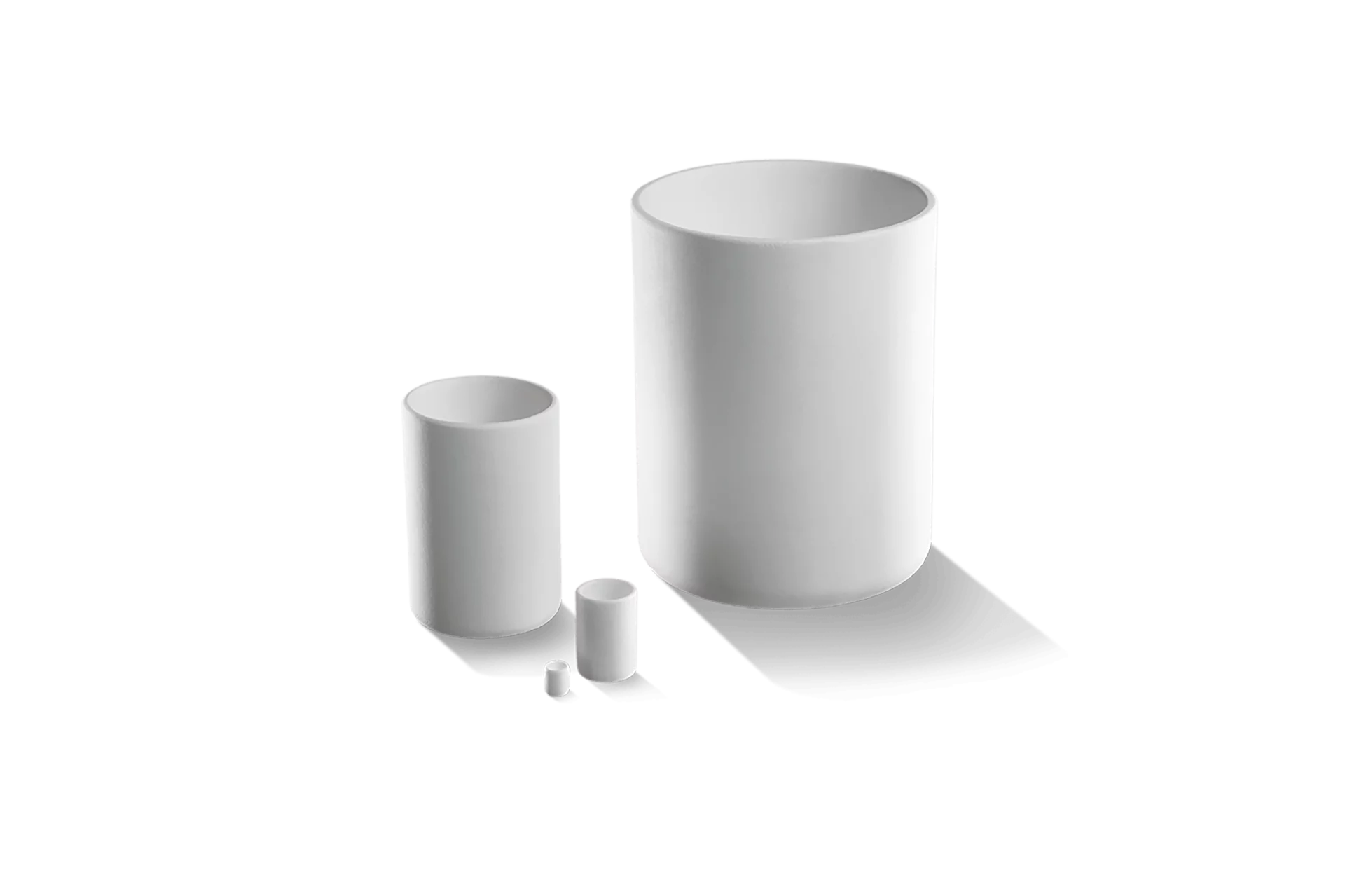

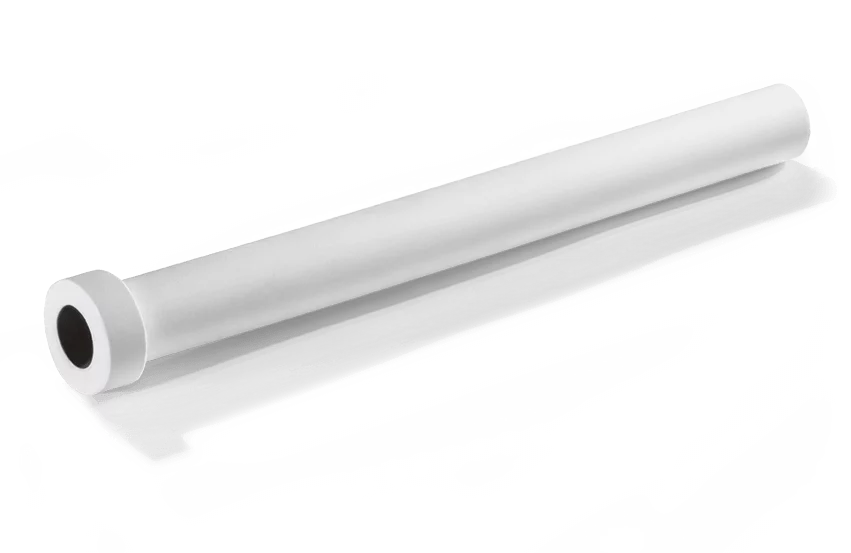

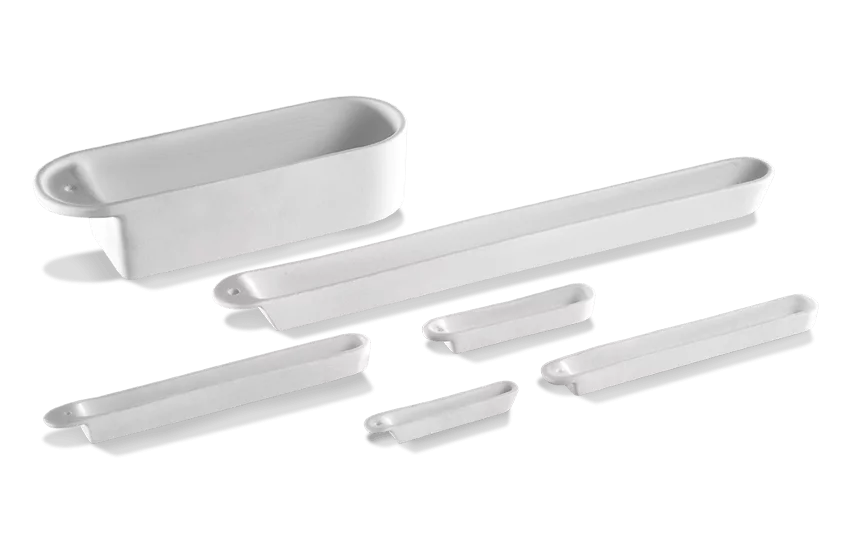

Technical ceramics for chemical engineering:

- very reliable

- chemically inert

- resistant to corrosion

- high temperatures and thermal shock

- immune to/resistant to impurities

- immune to/resistant to undesirable chemical reactions

- also suitable for aggressive environments

Brochure: Pyrometry, Laboratory Ceramics & Furnace Construction

Schunk Technical Ceramics

Add

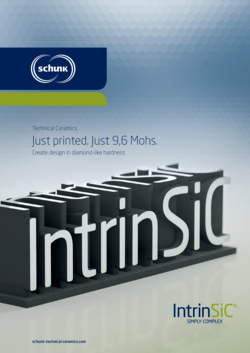

Brochure: IntrinSiC® 3D-printing

Create design in diamond-like hardness

Add

Downloads

2 Files online