Advantages of technical ceramics for metrology components

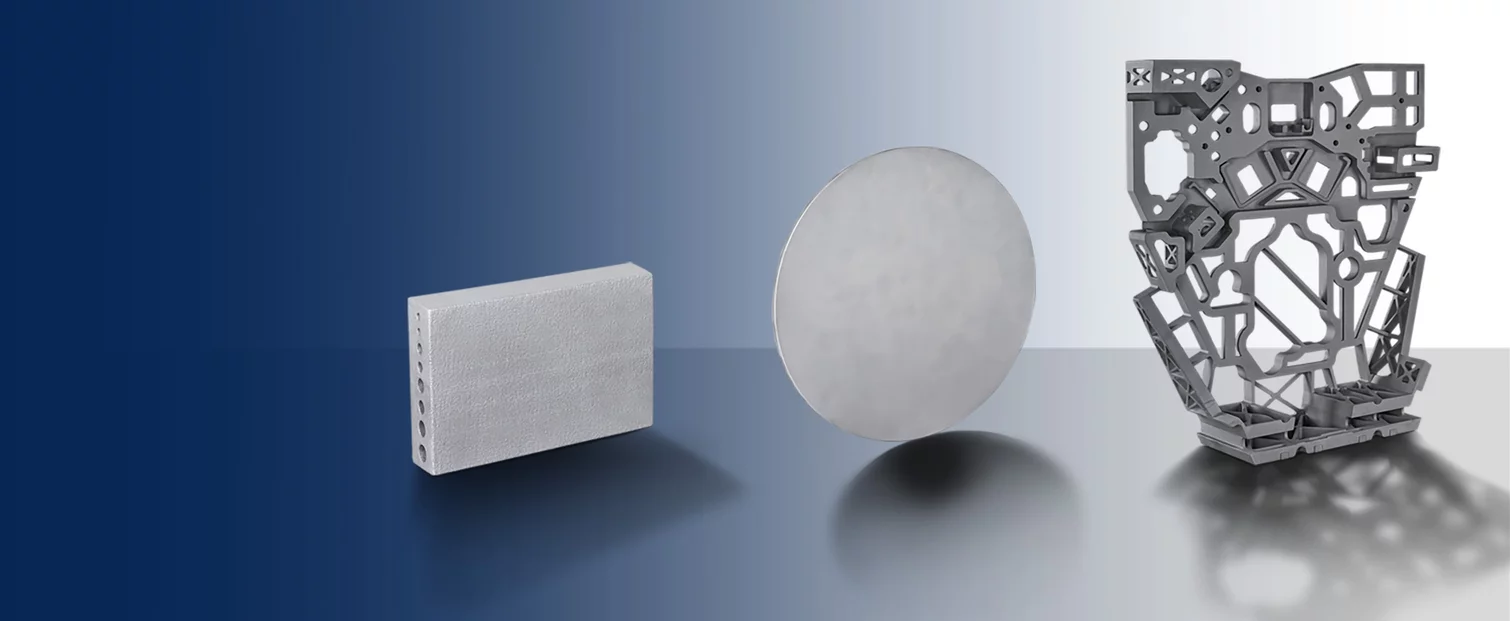

- RB-SiC variants: CarSIK-NG, IntrinSiC®.

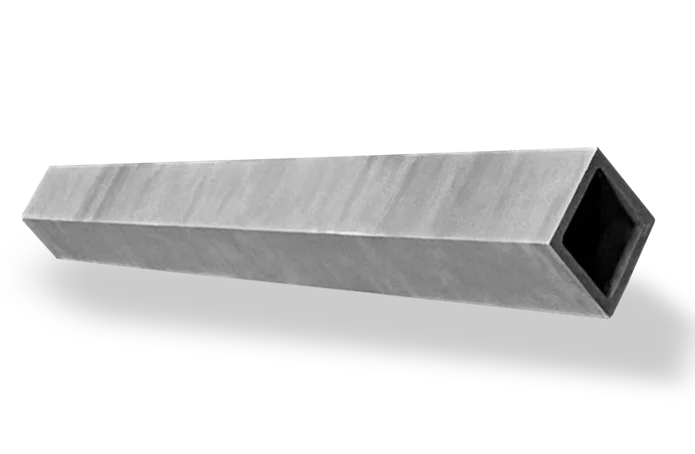

- High flexural strength, creep strength, and stiffness

- Large components (1.8x1.0x0.7m) in one piece with maximum design freedom at the same time

- No open porosity

- Economical production of high quantities

- Very low coefficients of thermal expansion as well as high thermal conductivity up to 200 W/mK

- High oxidation and corrosion resistance

- As a variant unique in the world: production by 3D printing with IntrinSiC®