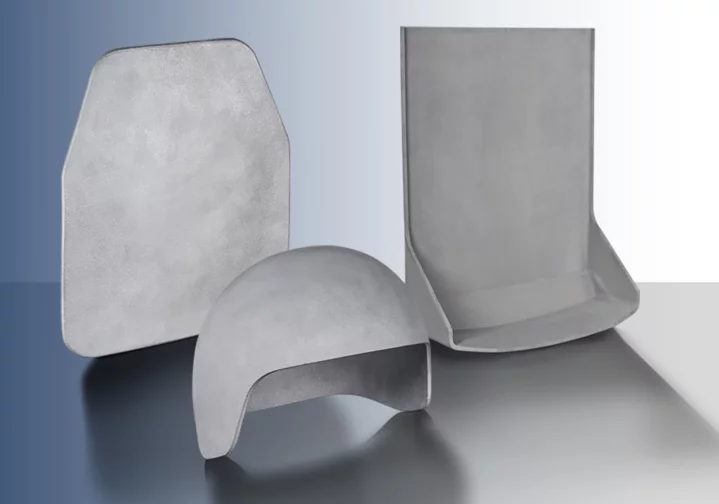

SafeGuard GD: Robust standard solution for series helmets

- Reaction-bonded silicon carbide (RBSiC)

- Density: 3.10 g/cm³

- Hardness: 25,000 MPa

- Ideal for series helmets, e.g., police, military

In tactical operations, special operations, or urban crisis situations, one thing is clear: the human head remains one of the most vulnerable targets. That is why ballistic helmets are an indispensable part of modern protective equipment. They offer protection against bullets, shrapnel, and blunt force—and must be lightweight, stable, and reliable.

However, what is often overlooked is that the actual protective mechanism of these helmets is not in the outer shell, but inside – in an invisible layer of technical ceramics. This is exactly where Schunk comes in.

We supply the crucial ceramic components on which many high-performance helmets worldwide are based. Materials such as SafeGuard GD and SafeGuard B4C protect thanks to their exceptional hardness, low weight, and ability to fragment even armor-piercing projectiles and absorb the impact energy.

Thanks to innovative processes such as 3D printing with IntrinSiC®, even complex helmet structures can now be produced – precisely fitting, lightweight, and highly effective.

So anyone who thinks that protection is just a matter of the shell has not looked at the core: that is where safety begins – with high-performance ceramics from Schunk.

A ballistic helmet is much more than just head protection. It is a complex safety system designed to protect the wearer from firearms, shrapnel, impacts, and explosive forces. Originally reserved for military units, ballistic helmets are now standard equipment for special police units, private security services, and special forces worldwide.

A modern helmet consists of several layers and components:

The ceramic component plays a key role here: it is responsible for fragmenting incoming projectiles and reducing the impact energy before it is transmitted to the head.

Ballistic helmets are classified according to international standards:

Today, a ballistic helmet is a high-tech product – and the ceramic used determines its protective potential.

While outer materials such as aramid or polyethylene are clearly visible in ballistic helmets, the crucial protective material remains hidden: ceramic hard ballistics. This thin, extremely hard layer inside the helmet is responsible for ensuring that projectiles are destroyed rather than penetrating the helmet – often in a fraction of a second.

Upon impact, a projectile hits the ceramic plate. Thanks to its high hardness, it immediately fragments the projectile. The resulting fragments are stopped by the subsequent layers (e.g., fibers, damping material). The major advantage is that the kinetic energy is absorbed before penetration and distributed over a larger area, drastically reducing the risk of serious head injuries.

Compared to traditional metals such as titanium or pure plastic solutions (PE), technical ceramics offer significant advantages:

Schunk supplies the critical ceramic materials that make their protective effect possible. With one of the world's broadest portfolios of high-performance ceramics for ballistics, the company offers everything manufacturers need to produce state-of-the-art helmets – from series solutions to customized high-end components.

Type: RBSiC

Density: 3,10 g/cm³

Hardness: 25.000 MPa (Vickers)

Special features:

Robust standard material

Ideal for helmets in serial production

Type: RBB4C

Density: 2,85 g/cm³

Hardness: 29.000 MPa (Vickers)

Special features:

Extremely lightweight

Maximum protection

Type: RBSiC (3D)

Density: 3,05 g/cm³

Hardness: 25.000 MPa (Vickers)

Special features:

Design freedom through 3D-printing

for complex helmet shapes possible

Type: RBB4C (3D)

Density: 2,88 g/cm³

Hardness: 29.000 MPa (Vickers)

Special features:

Lightweight

Customization via 3D-printing

Ballistic helmets today are much more than simple protective shells – they are high-tech systems in which every gram, every shape and every material counts. At the heart of this development is technical ceramics.

As one of the leading suppliers of high-performance ceramic materials, Schunk provides the invisible but crucial component that gives modern helmets their protective effect. Whether with the proven SafeGuard GD, the ultra-light SafeGuard B4C or the innovative 3D-printed IntrinSiC® solutions – ceramics from Schunk mean state-of-the-art protection.

Ceramic protection starts on the inside – where it counts. And Schunk ensures that this protection delivers what it promises.