Advantages

Leading technology from the world's 3rd rail experts

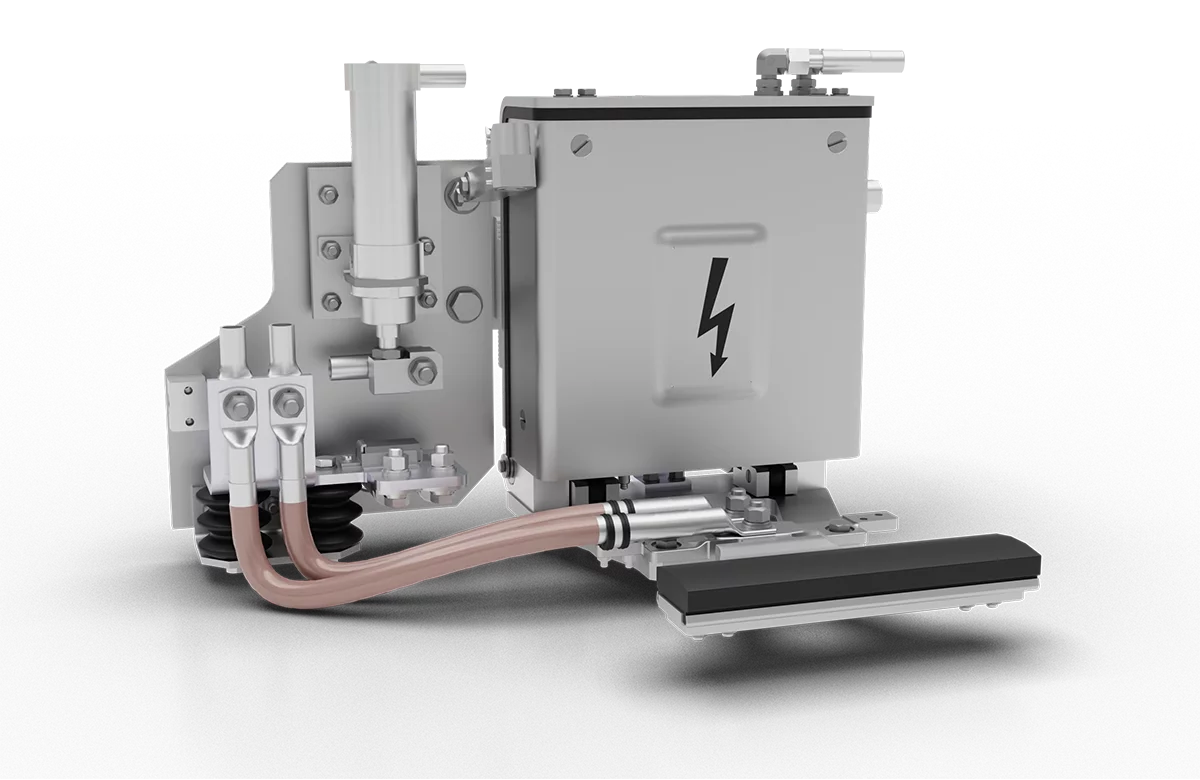

- Diverse applications thanks to a variety of base designs and customer-specific adaptations

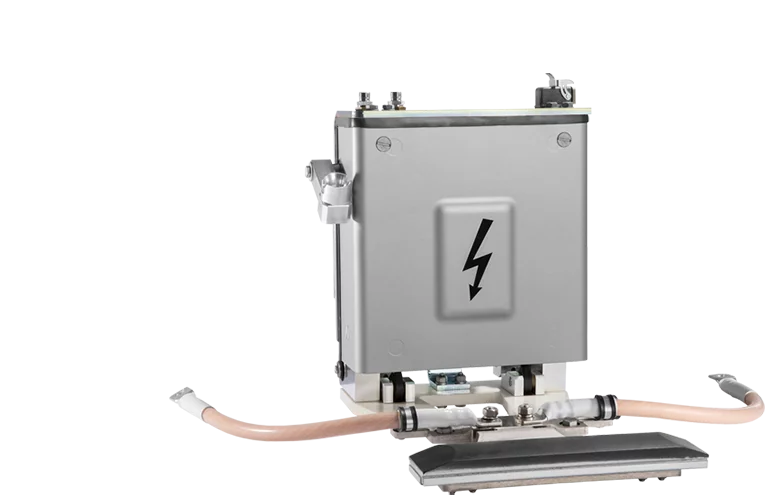

- Patented Schunk multi-system collectors can contact conductor rails from the bottom, top or from the side

- A second layer of insulation makes the current collectors especially safe against short circuits that may be caused by metallic waste in the track bed

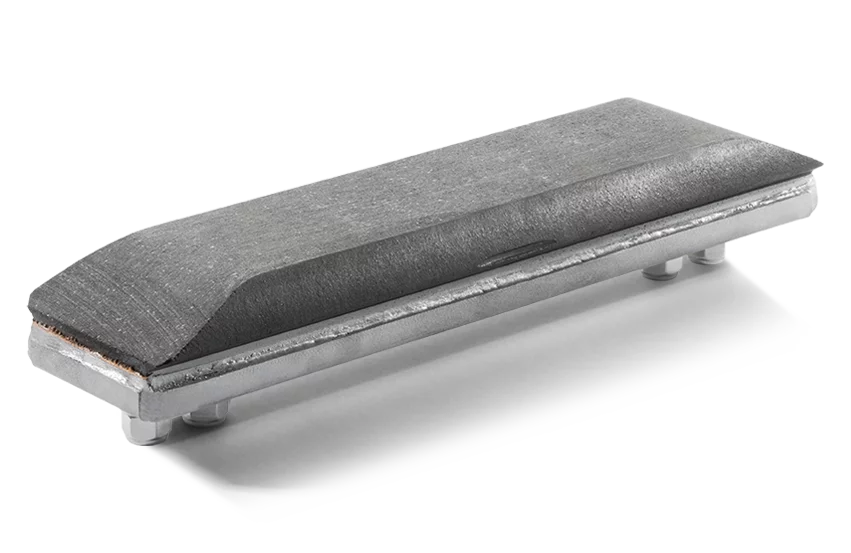

- The safety-relevant intercepting device for our contact shoes prevents contact shoes from being lost if they collide with obstacles

- Integrated or separate fuse boxes with specialized fuses protected against vibration protect the vehicle technology and wiring against damage in case of an electrical malfunction

- Everything from a single source – including wear parts and service

Brochure: Schunk Transit Systems

Pioneering solutions for the rail and bus industry

Add

Downloads

1 Files online