Advantages

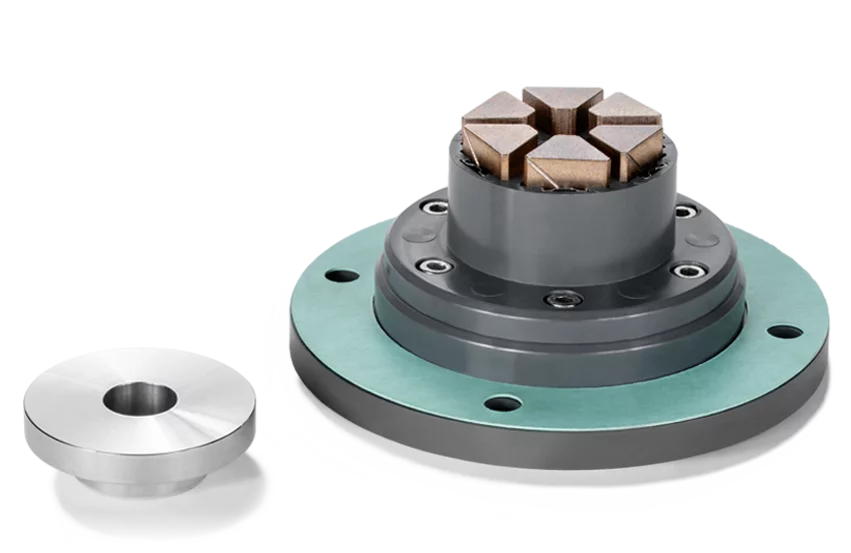

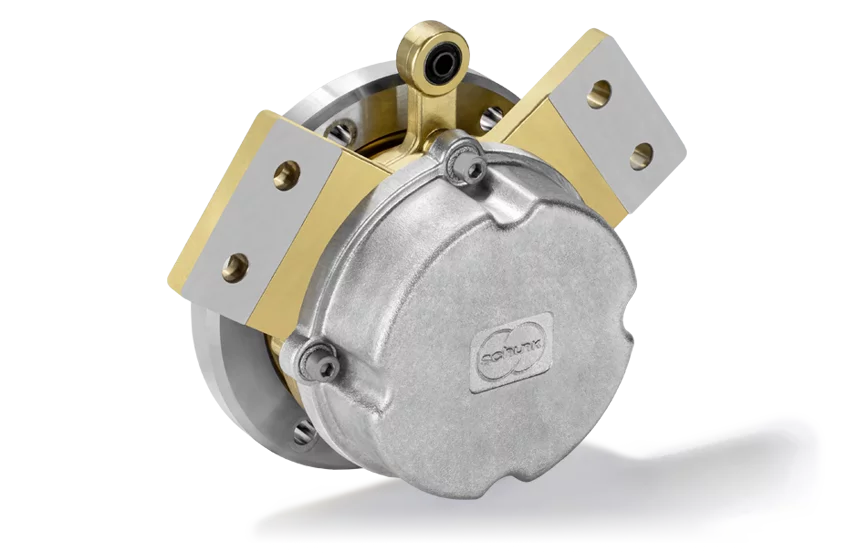

Reliable grounding contacts for the railroad industry

- Extremely long service life of all grounding contacts

- Various systems cover all common installation situations and interfaces

- High level of design and development expertise

Innovative shaft grounding for trains & railroads

-

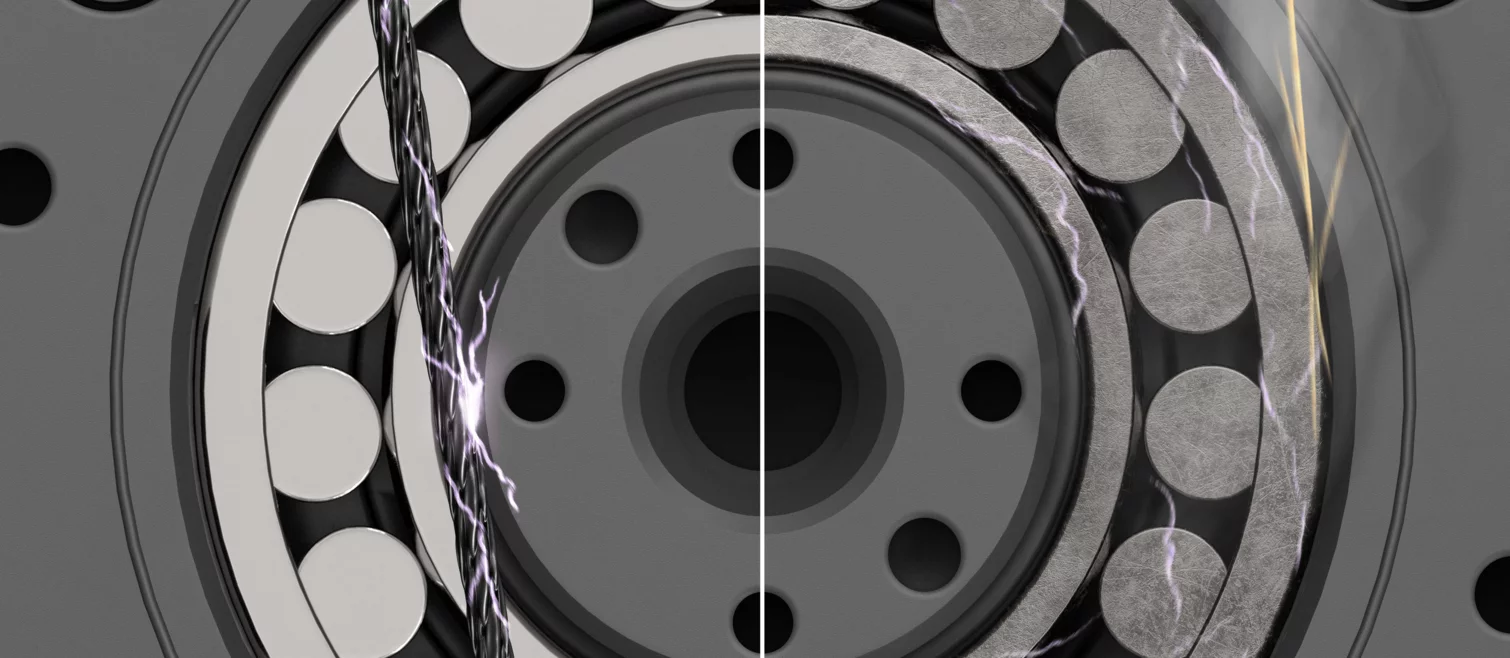

The system prevents expensive bearing damage

- Fast amortization due to lower repair and maintenance costs

- Slim design enables use in compact installation positions on the bogie

Brochure: Perfect Grounding

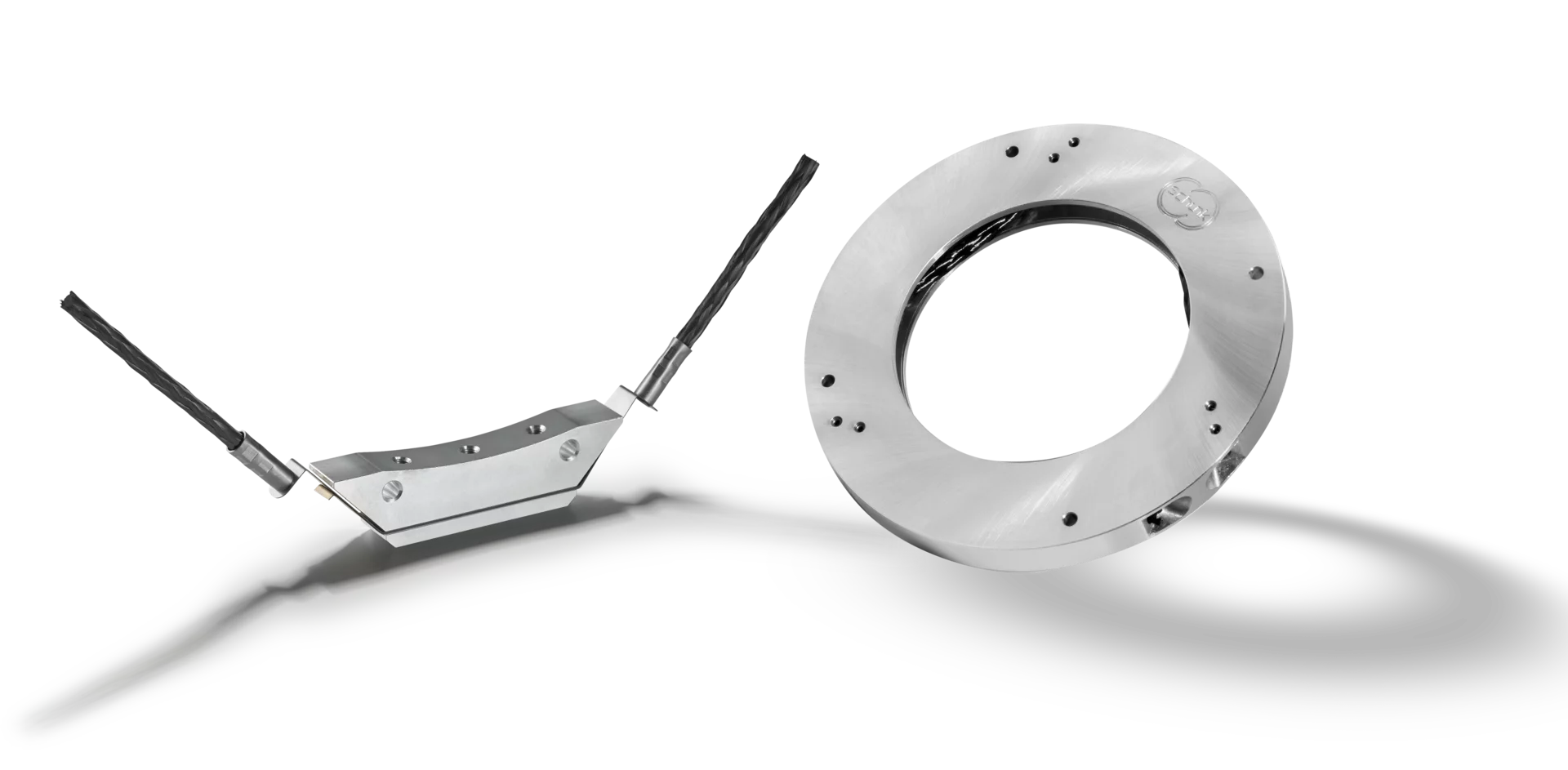

CFG - Carbon Fiber Grounding

Add

Case Study: Dessauer Verkehrsbetriebe GmbH

Shaft Grounding System from Schunk saves transmission bearings in Dessau tramways

Add

Case Study: Verkehrsbetriebe Karlsruhe

Grounding System from Schunk Solves Long-standing Problem of Public Transport Company in Karlsruhe

Add

Downloads

3 Files online