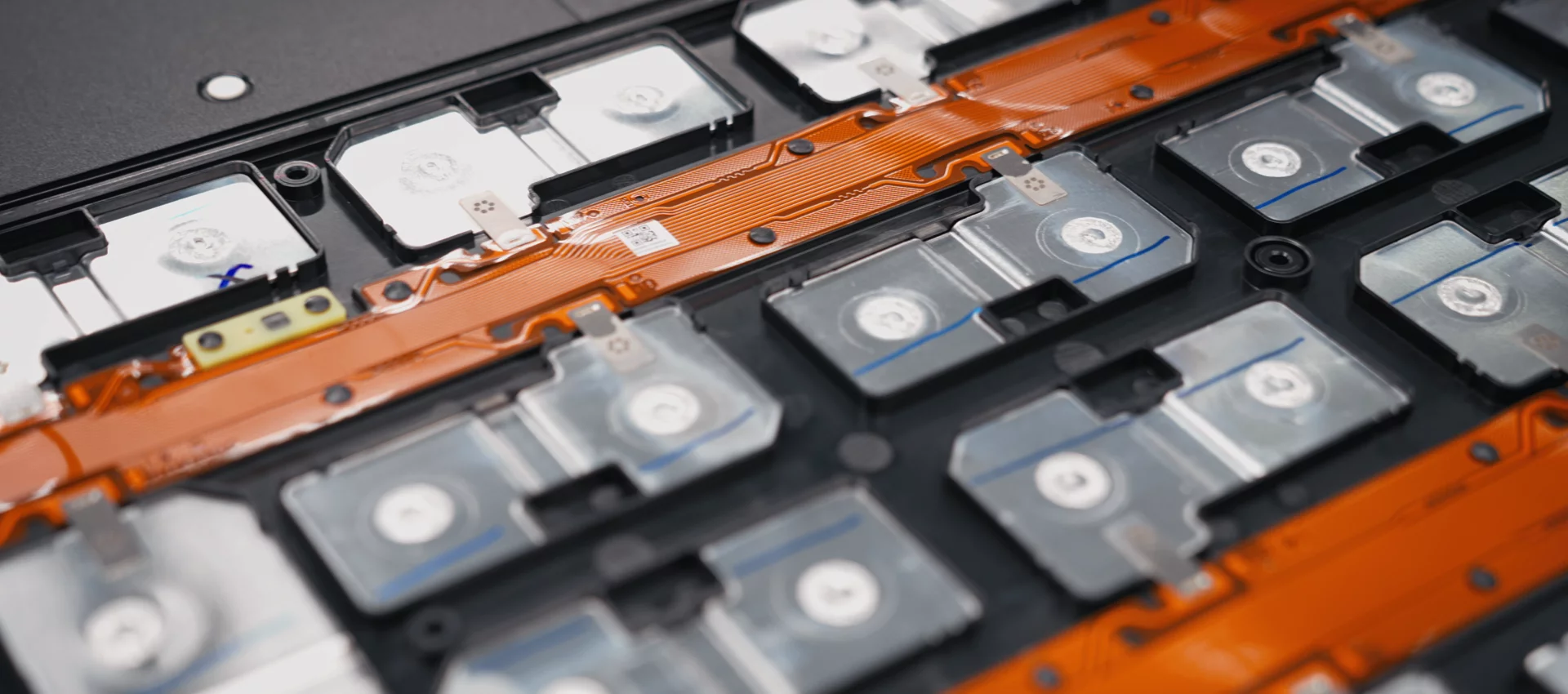

Wiring Harnesses and Battery Management

Ultrasonic welding is the proven joining technology for high‑quality automotive cable harness production. It creates fast, clean, and highly stable metal‑to‑metal connections for strands, terminals, and splices - without solder, minimising heat input and thermal damage.

-

Maximum process reliability for strands and splices

Consistently reproducible quality, even with thin conductors and complex cable bundles.

-

Very short cycle times for series production

Robust, fast, and clean processes - ideal for fully automated production lines.

-

No thermal stress on conductors

No weakening of materials, ensuring long service life and high vibration resistance in automotive applications.