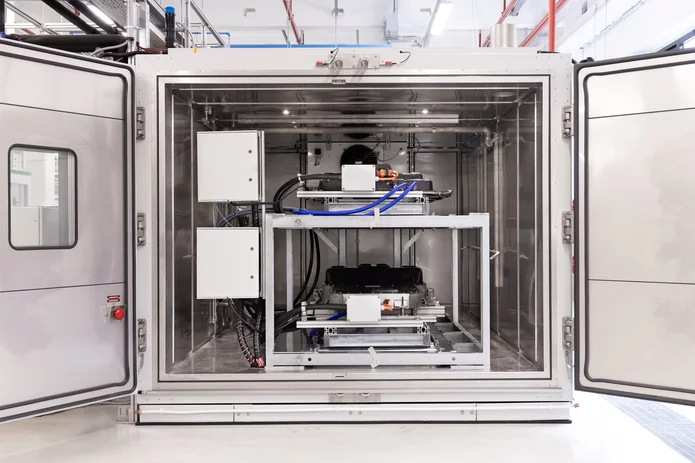

Ultrasonic welding - busbars

Ultrasonic welding is the proven standard for busbar joining in battery production. It enables fast, safe, and high‑strength metal‑to‑metal connections with minimal heat input - ideal for automated high‑voltage applications.

-

Extremely strong high‑current connections

Perfect for HV busbars, delivering low contact resistance and maximum conductivity.

-

Fast, robust process for series production

Short cycle times, high reproducibility, and no additional filler materials.

-

Minimal heat input, even with thick cross‑sections

No structural damage or insulation melting - a process‑reliable solution for e‑mobility production.