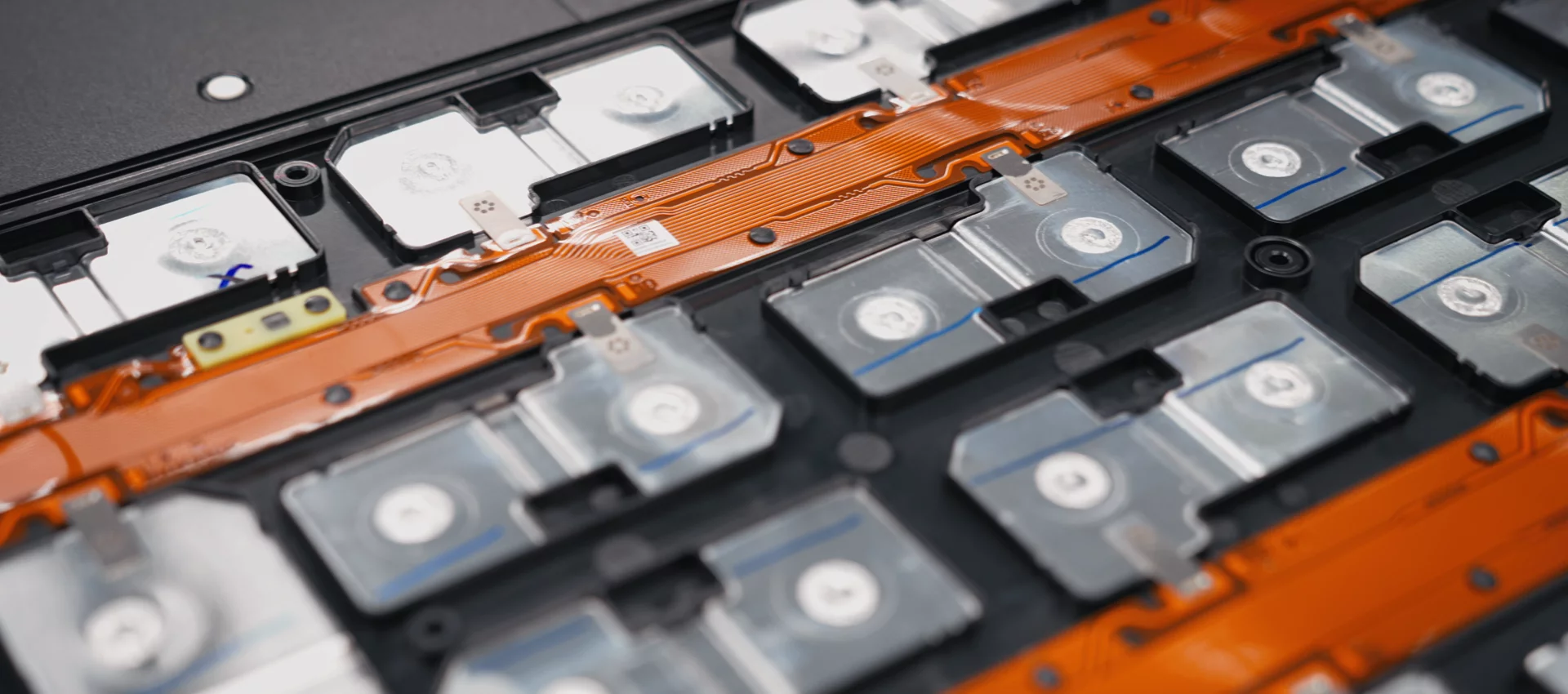

Bonding of Cell Housings, Cell Contacting Systems, and Sensor Technology

Ultrasonic welding enables precise, high‑strength connections for cell contacting and housing components

-

Minimal heat input, maximum component protection:

Ideal for temperature‑sensitive sensors and cell conductors, with no risk of warping, or thermal damage.

-

High process stability with clean, reproducible results:

Perfectly suited for automated production lines with short cycle times and demanding quality standards.

-

Strong, durable metal‑to‑metal joints without additional materials:

Cost‑efficient, reliable, and ideal for high‑current applications in battery systems.