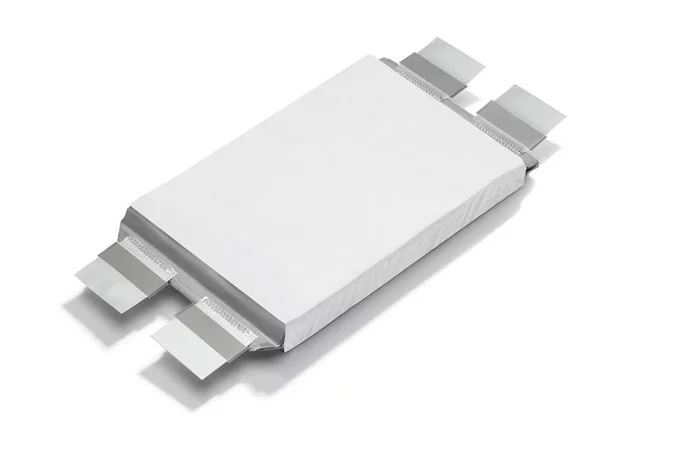

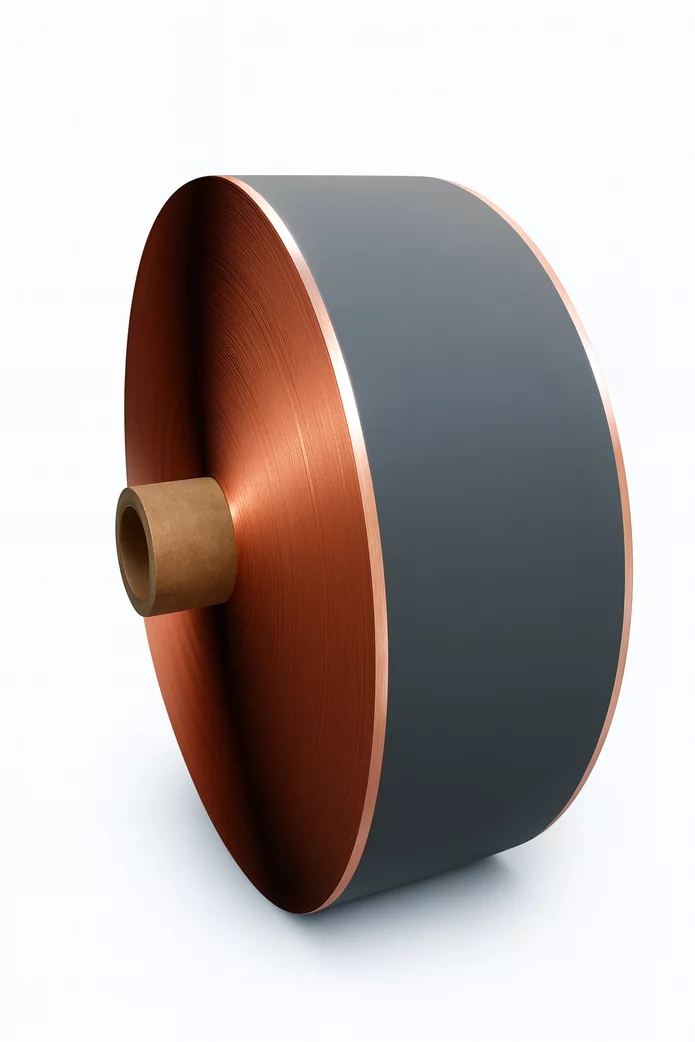

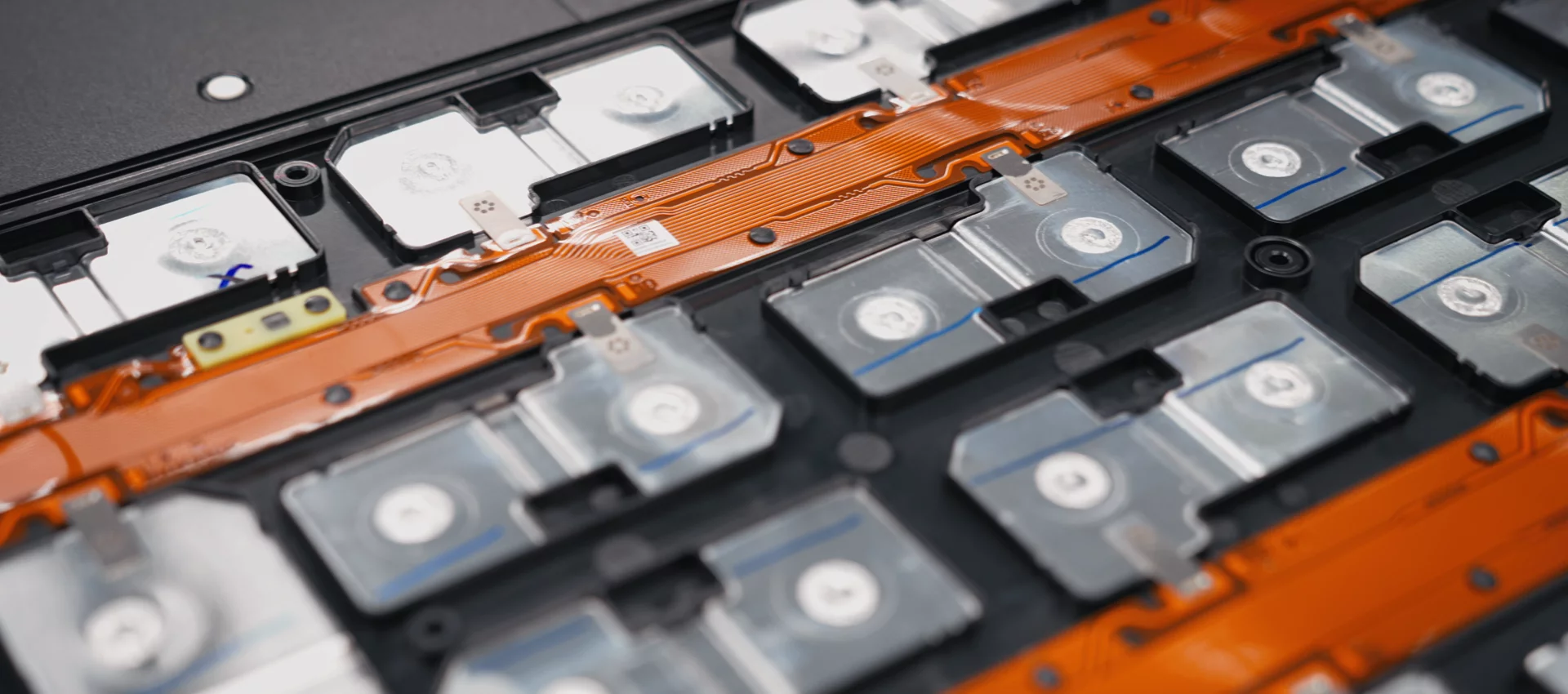

Ultrasonic Compacting and Welding of Cell Conductor Tabs

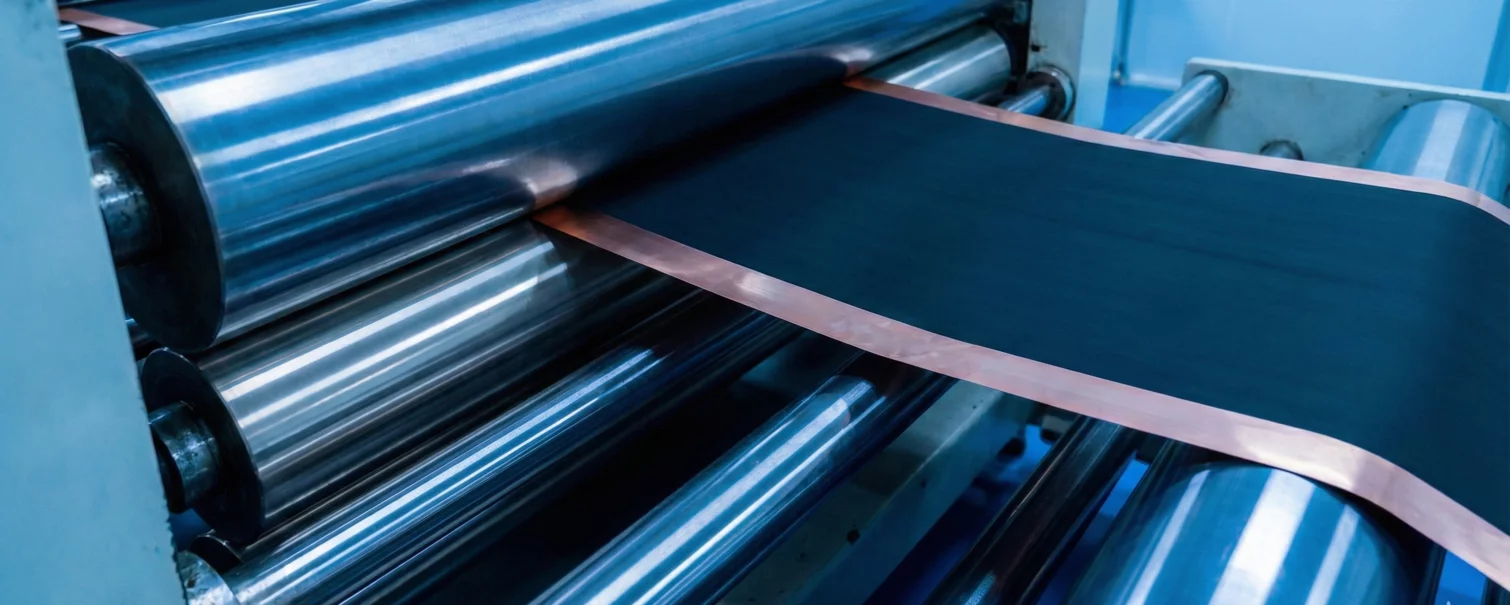

During ultrasonic compacting and welding, fine strands or foils are precisely compacted and welded to form high‑strength, reliable connections.

-

Low‑resistance, high‑strength connections:

Ideal for current paths in modern, high‑performance battery modules.

-

Integrated process control for reproducible quality:

Minimal contact resistance, stable connections, and significantly reduced scrap.

-

Minimal heat input for maximum material protection:

No thermal stress - perfectly suited for sensitive cells and thin conductor geometries.