Ultrasonic metal welding for reliable cable connections

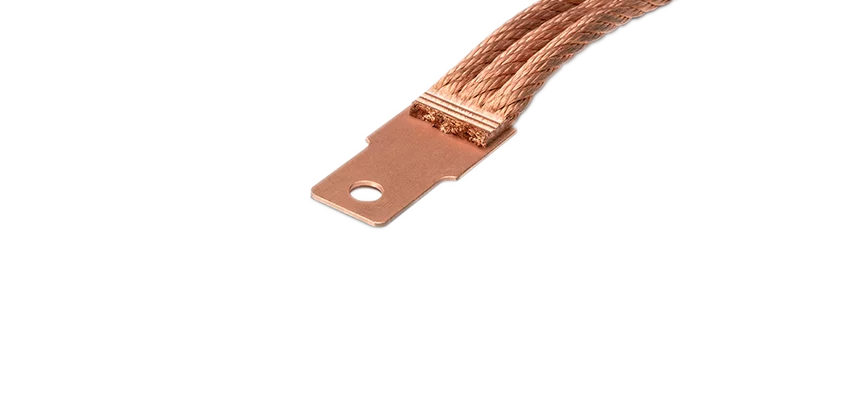

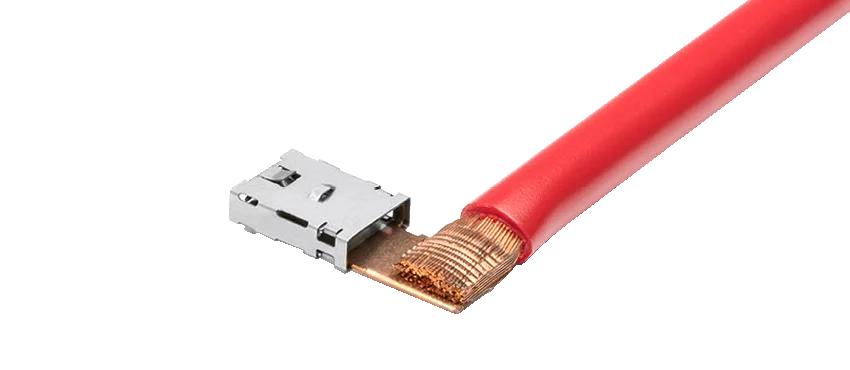

Ultrasonic metal welding is one of the most important joining technologies employed in the manufacture of wire harnesses for the automotive, construction equipment and household appliance industries. Among other things, the process is used for joining multiple wires with each other as well as for joining wires with grounding terminals or high-current contacts. The wire cross-section sizes which can be ultrasonically welded ranges from 0.08 square millimeters to 200 square millimeters. Compared with crimping or resistance welding, ultrasonic welding offers numerous advantages. These include the excellent electrical properties of the joint, extremely low energy consumption and comprehensive process control and corresponding process data management.

Learn more about our terminal and splicing machines.

Introduction to ultrasonic metal welding

Let's find out.