Efficient and flexible wiring harness production:

welding all cross-sections without tool changes

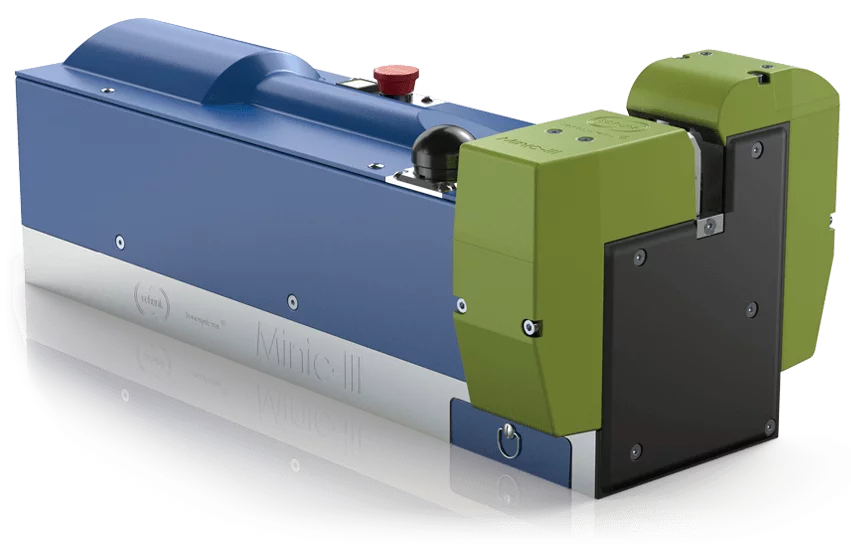

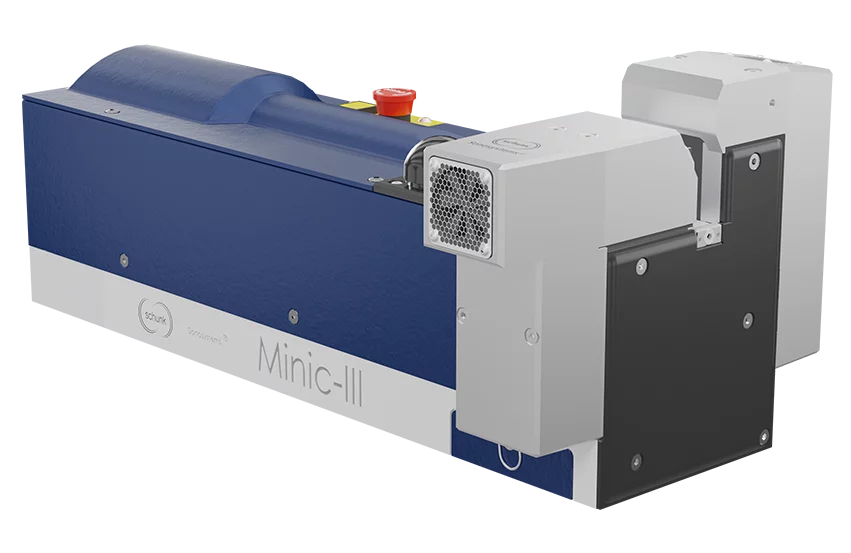

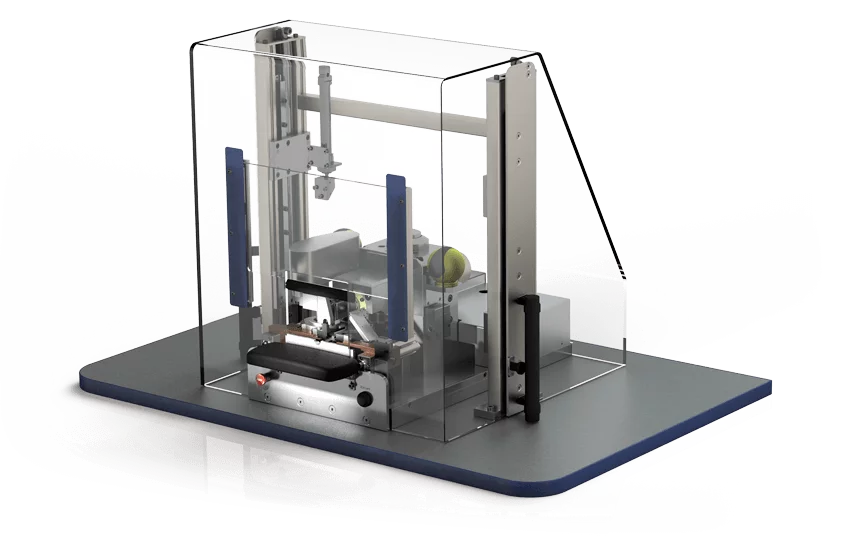

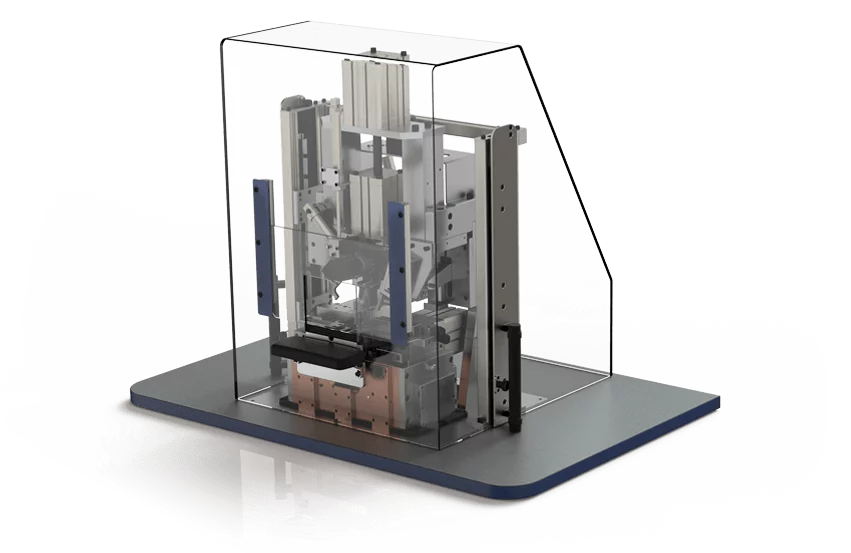

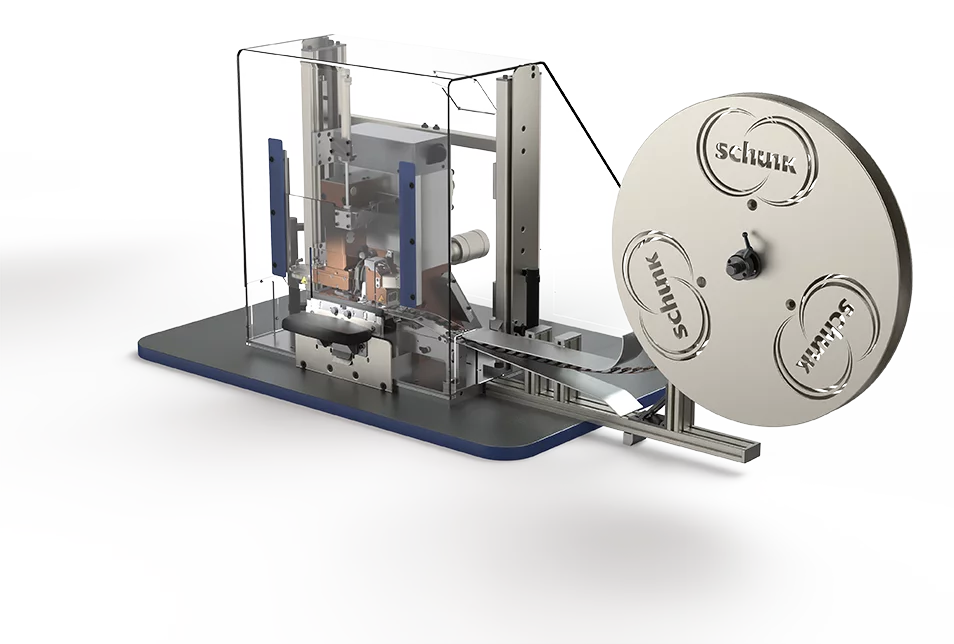

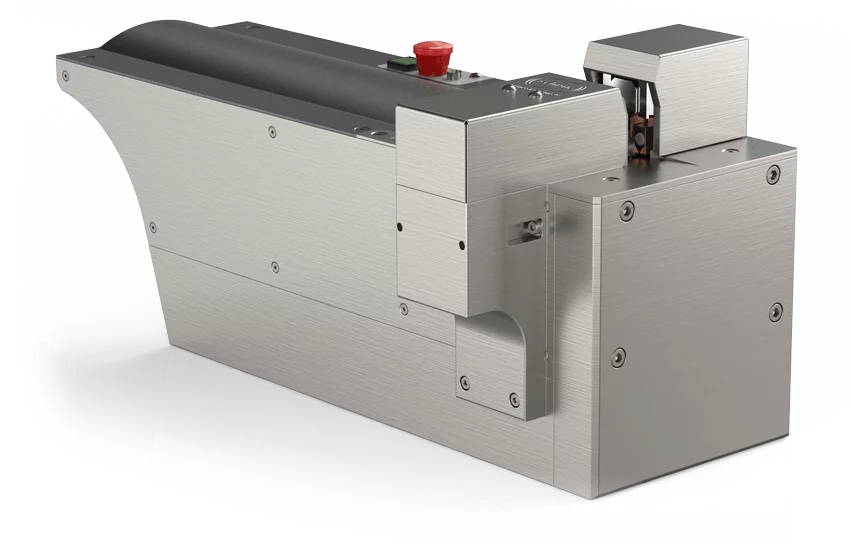

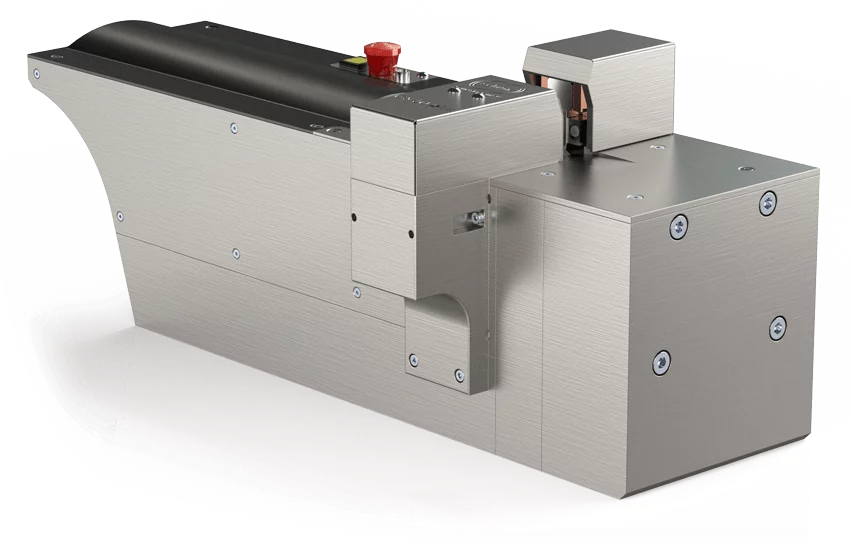

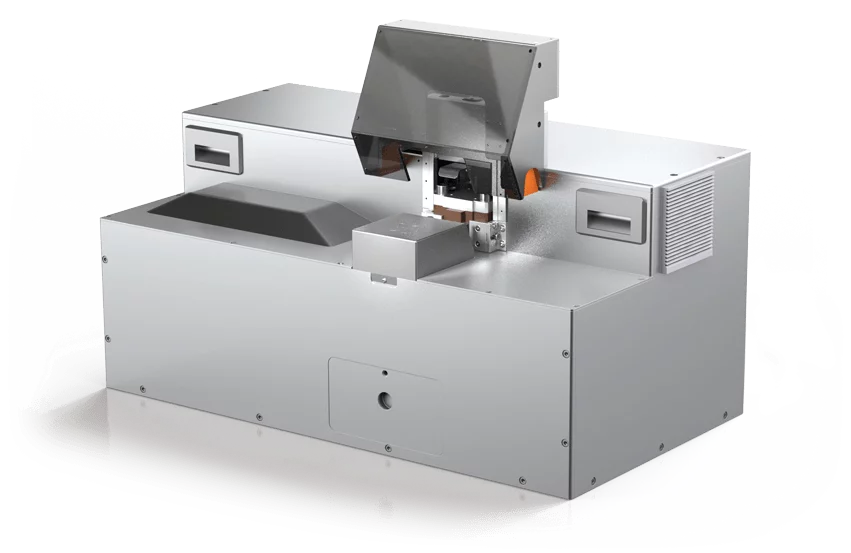

Quality, process reliability and flexibility are the hallmarks of good wire harness production. Our technologically leading machines enable you to achieve these characteristics for your production lines. The Minic series covers almost the entire cross-section range in the cable harness (from 0.26 mm² to 30 mm²) - without tool changes or mechanical modifications. The Global Splicer Series is suitable for welding aluminium, copper and mixed joints with cross-sections up to 50 mm². The LS series was specially developed for large cross-sections up to 200 mm². Connections of lines with various terminals, such as MAK or MAS, are also possible. All machines are suitable for welding mixed aluminium-copper joints - without modifications or tool changes.

Let's find out.

Learn more about our terminal and splicing machines.

Introduction to ultrasonic metal welding