Schunk Technical Ceramics

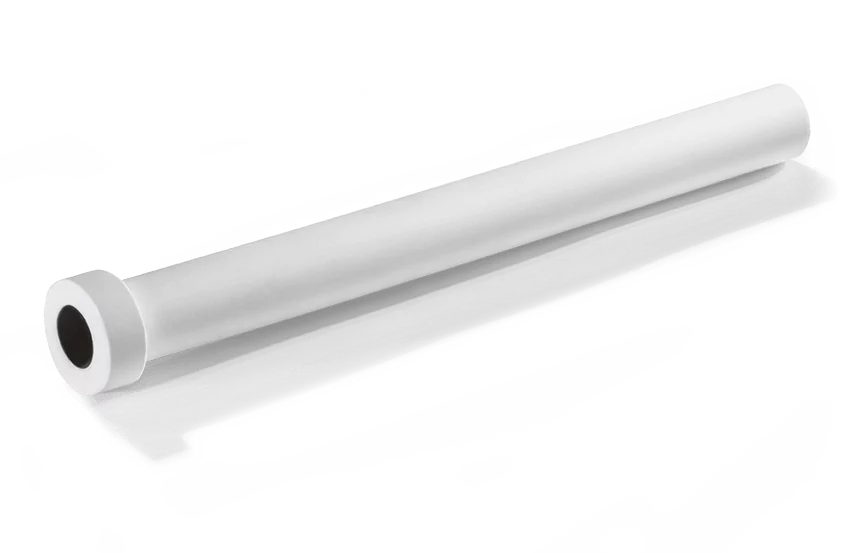

Rollers

Rollers as conveyer rollers are used for Roller Hearth Kilns in various industries (i.e. calcination of cathode active materials for Lithium- Ion- batteries, sanitaryware, Ferrites, Dinner-/Tableware, Architectural Ceramics). The preferred grade for a max. operation temperature of 1.380°C is RBSiC (silicon- infiltrated, reaction- bonded silicon carbide) due its superior material properties. Our extruded RBSiC grade CarSIK-Z exhibits an up to approx. 40% increased bending strengths compared to commercially available competitor materials. Due to the superior combination of high bulk density whilst having low content of free Si our Rollers achieve an outstanding Bending Strengths as well as Creep-Resistance which warrants a high degree of safety in operation in particular during standstill of the Rollers without rotation under full load at elevated temperatures.

You benefit from these advantages:

- Available Grade: RBSiC (CarSIK-Z)

- Excellent Bending Strengths and Creep- Resistance

- Excellent Oxidation- and Corrosion Resistance

- Very good Thermal Shock Resistance

- Low warpage tolerances (TIR)

- Available length up to 4200mm (in all mounting-installation configurations for driving systems)

- For special applications: ovality ≤0,1mm, TIR ≤3mm, Ra ≤ 1,0

for Calcination of Cathode Active Materials (CAM)

for Calcination of Cathode Active Materials (CAM)