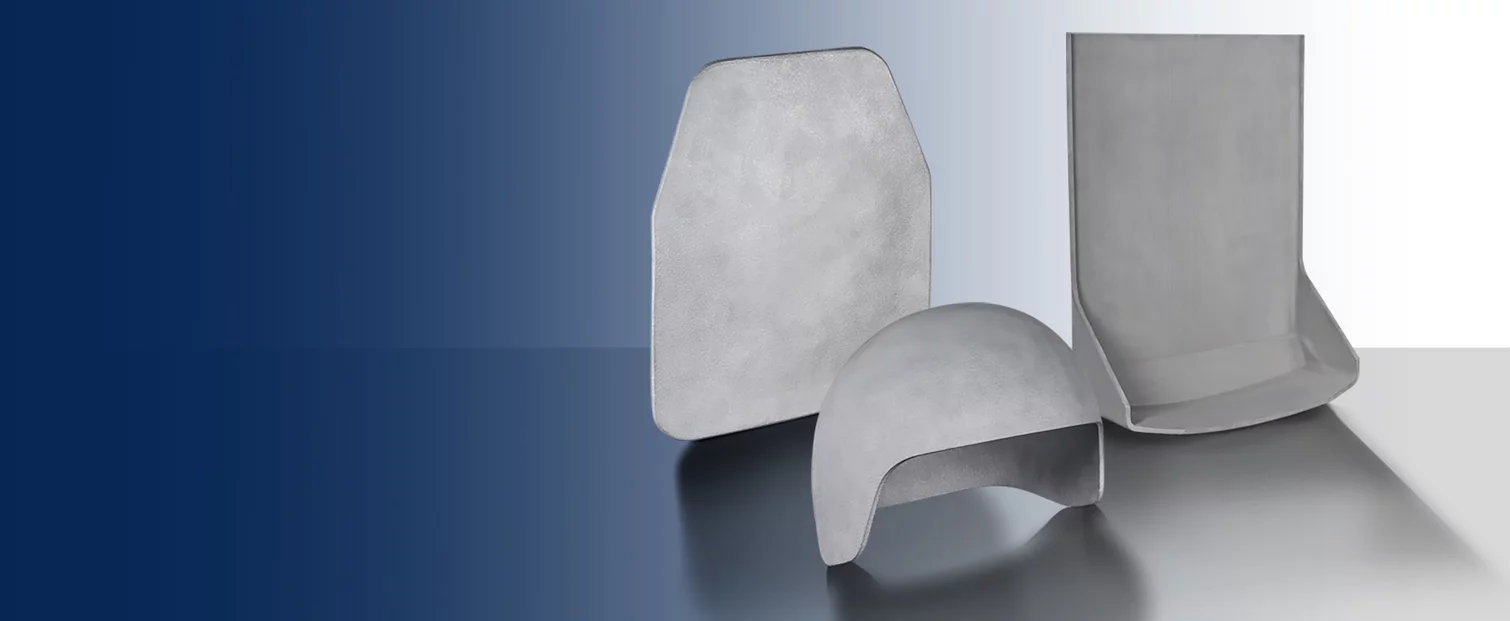

Body Armor

Being a hard ballistic component, monolithic ceramic plates are used in the highest protection classes to break up armor-piercing projectiles upon impact and to absorb some of the kinetic energy and distribute it to a larger area.

Whether ceramic armor plates for aviation, vehicle construction or personal protection – as a long-term supplier to these industries, we know what matters. For protection in high protection classes of safety-relevant components, high-performance ceramic materials are needed that have special properties.

What do personal protection and vehicle armor have in common? In both cases, you need equipment that consistently defeats threats and offers maximum protection. In both areas weight also plays an important role. In order to be comfortable to wear, protective vests and shields must be as light as possible.Vehicle armor must be light to reduce wear-and-tear on the drivetrain, suspension, and chassis.

Ballistic protective vests and shields have to defeat small arms and rifle attacks to protect soldiers and police officers. In combination with suitable fiber composite backing, they withstand projectiles with high penetrating power even with multiple shots. They ensure that high-hardness core projectiles break and erode upon impact. The kinetic energy is thereby divided into lower momentum fragments that are more easily caught within the composite plate. The use of portable, compact, yet highly effective and reliable solutions of low weight solutions plays an important role in the field of personal protection. The focus here is on the users acceptance of the protective equipment and their remaining mobility in hazardous situations. The combination of high hardness and low density of the ceramic armor plates predestines our product for lightweight solutions with high protection performance. Thanks to our leading production technology, we are able to flexibly supply both prototype samples and large series-production quantities in reproducibly high quality and on time.

Ground vehicle protection usually involves the dimensionally accurate covering of large, complex surfaces. This is made possible by the use and design of mosaic panels made up of smaller hexagonal and square tiles. Such multi-tile setups also increase the ability to withstand multiple impacts. The combination of high hardness and low density of the plates predestines our product for lightweight solutions with high protection performance. Thanks to our leading production technology, we are able to flexibly supply both prototype samples and large series-production quantities in reproducibly high quality and on time.

For ballistic protection of aircraft, larger area panels can be used to achieve the ballistic effectiveness, usually with lower velocity requirements and reduced multihit requirements. Thanks to our modern production technology, we are able to create a large variety of geometries characterized by very precise cuts, among other things. Optional holes and cut-outs are also possible via machine processing.

Schunk Technical Ceramics, as a leading expert in the field of technical ceramics, offers innovative solutions for a wide range of applications. Our high-quality technical ceramic materials enable maximum safety, especially in situations where ballistic impacts can pose a threat.

We redefine the limits

Schunk’s modern manufacturing technology - including 3D printing - enables us to offer a wide variety of geometries for prototypes, low-rate initial production, and full production quantities. Precise cuts as well as additional holes and recesses are made possible by machining. if not able to be implemented during the molding of the ceramic components.

Learn more about our 3D-printed technical ceramics

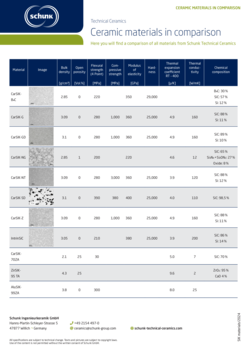

SiC & B4C armour materials for ballistic protection

Create design in diamond-like hardness