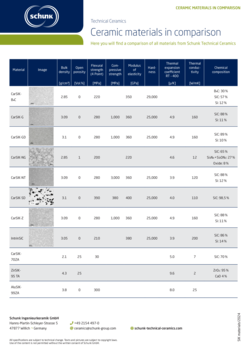

Materials used by Schunk Technical Ceramics

Comparison Chart: Materials

1 Files online

The advantages of our technical ceramics

Benefit from the possibilities and properties of our RBSiC variants CarSIK and IntrinSiC®

- Very low coefficients of thermal expansion

- High flexural strength and rigidity

- Bionic structures for minimum weight with maximum load-bearing capacity

- Supported by FEM simulation

- Precision machining in the µ range

- Very high Weibull moduli (> 15)

- Very good thermal shock resistance

- Production of large and complex components (1.8 x 1.0 x 0.7 m)

- Mirror polishing (under development)

- A globally unique variant: production using 3D printing with IntrinSiC®

Brochure: IntrinSiC® 3D-printing

Create design in diamond-like hardness

Add

Downloads

1 Files online