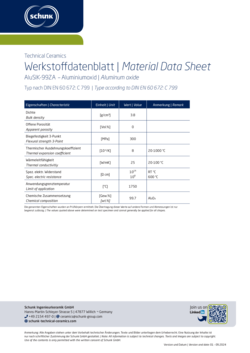

Material data sheet for AluSIK-99ZA

Special properties of aluminum oxide (Al2O3):

- Electrical insulation: 1×1014 - 1×1015 Ωcm

- Hardness: 15 to 19 GPa

- Density: 3.75 to 3.95 g/cm³

- Mechanical strength: 300 to 630 MPa

- Compressive strength: 2000 to 4000 MPa

- Thermal conductivity: 20 to 30 W/mK

- Flexural strength: 300 MPa

- Modulus of elasticity: 320 GPa

- Max. Application temperature: 1700 °C

- High corrosion and wear resistance

Datasheet: AluSIK-99ZA

Add

Downloads

1 Files online