Your advantages

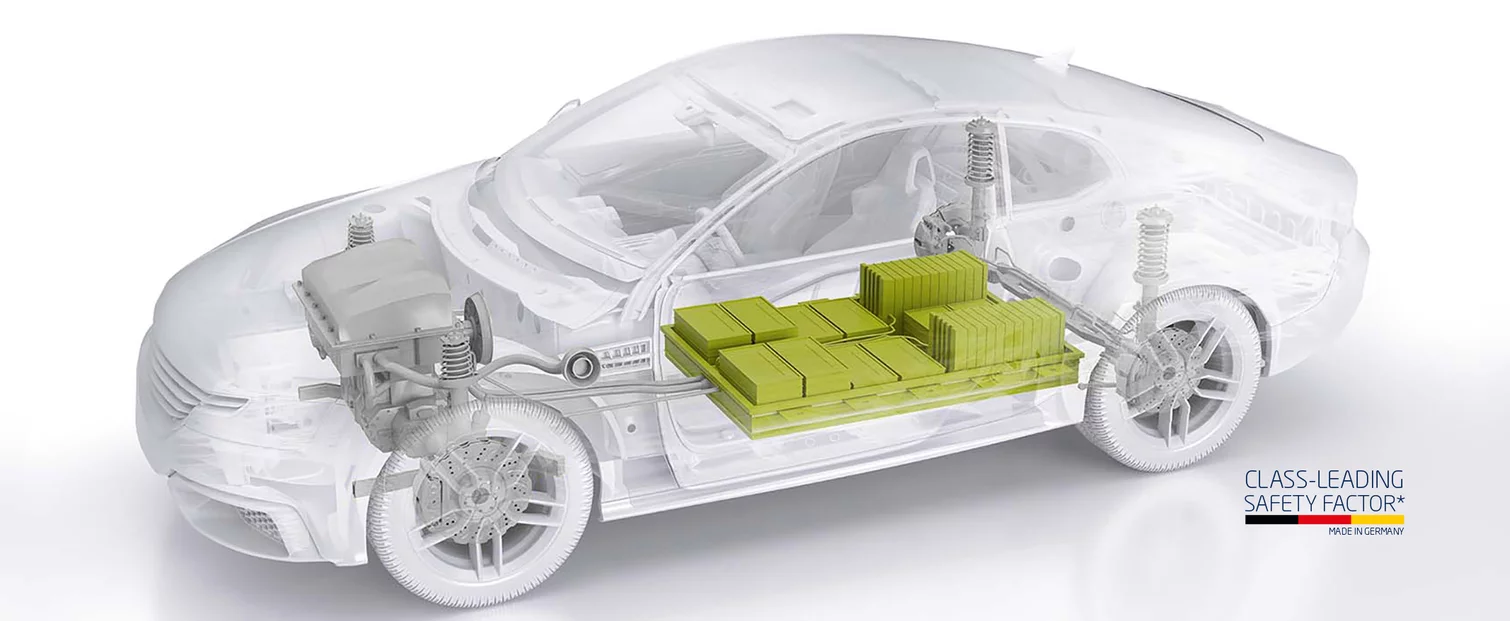

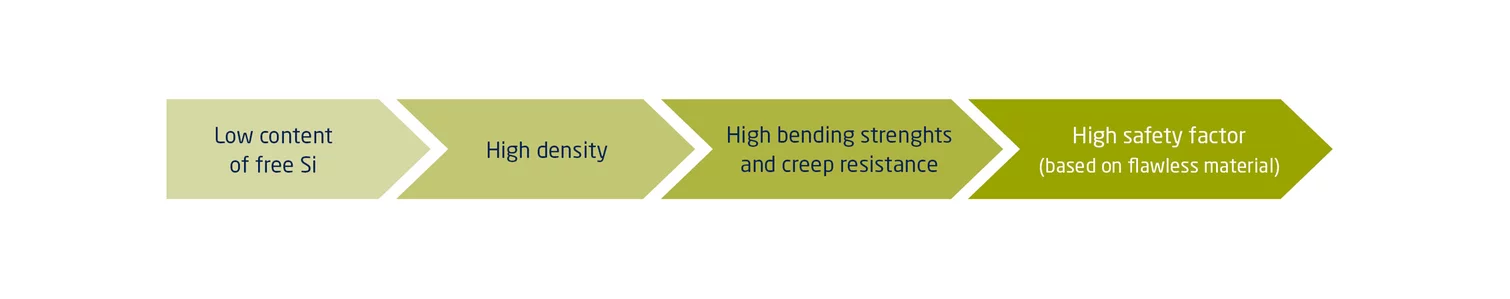

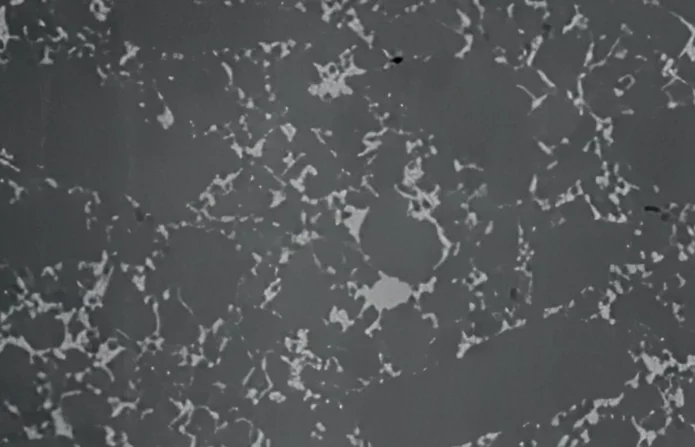

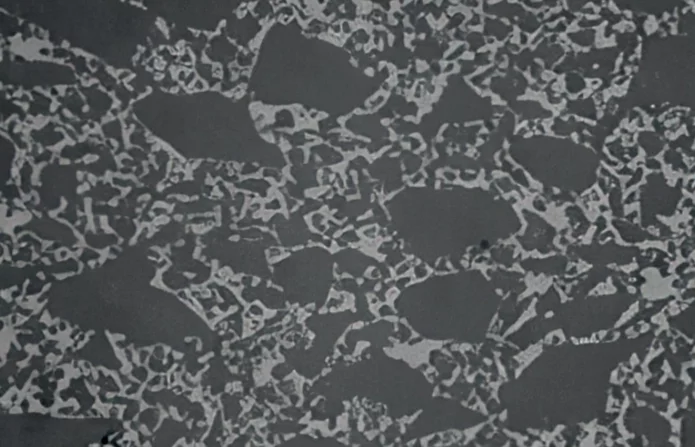

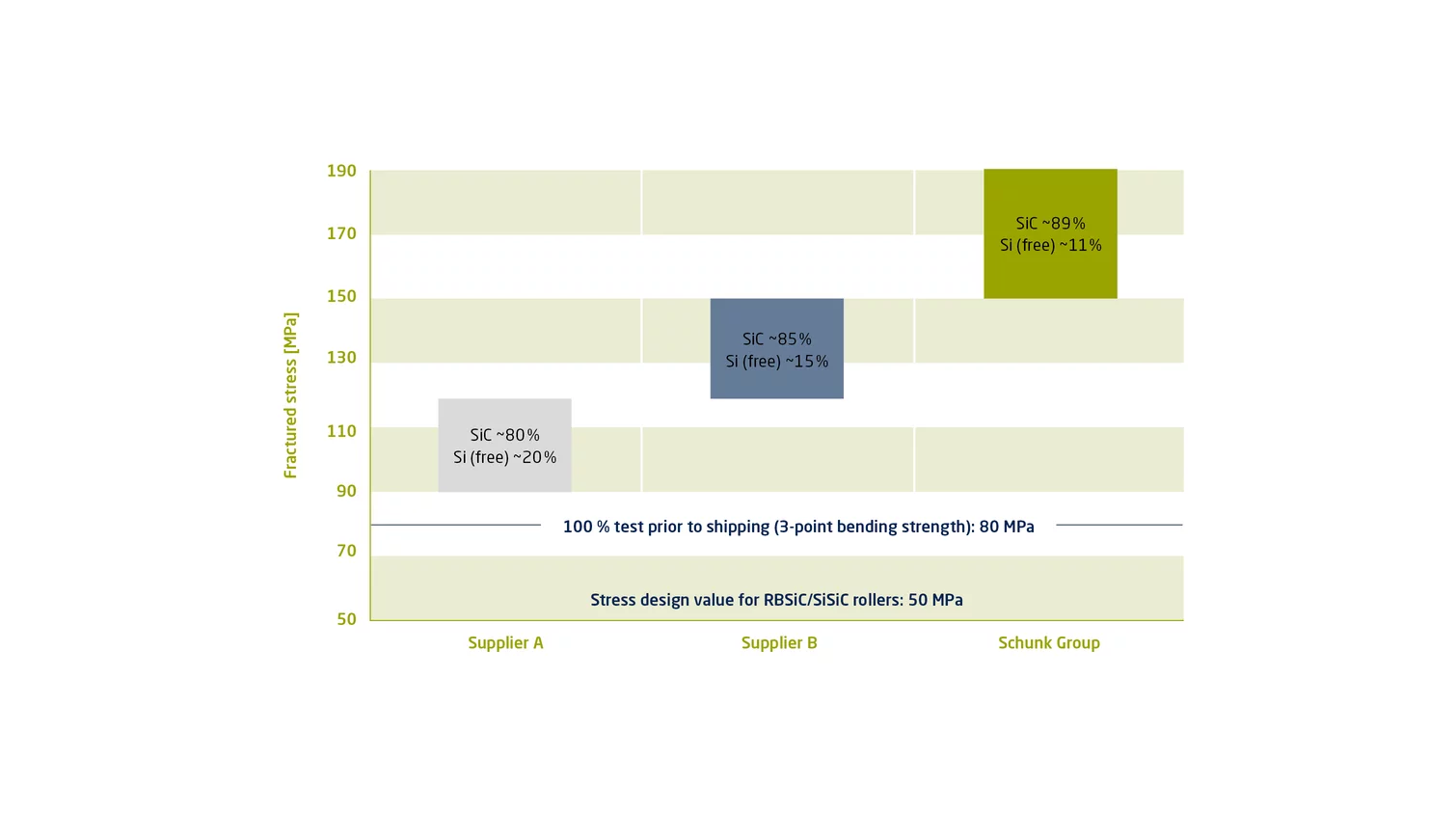

- Class- Leading Safety Factor (due to superior microstructure and highest bending strength and creep-resistance among currently all commercially available RBSiC/SiSiC grades)

- Tight TIR specification (incl. high degree of uniformity)

- Gastight material for outstanding oxidation resistance up to 1,380 °C

- Excellent thermal shock resistance

- Excellent chemical resistance (withstanding aggressive kiln atmospheres)

- Variable diameter and wall-thickness up to a max. length of 4,200 mm

Brochure: RBSiC Rollers

for Calcination of Cathode Active Materials (CAM)

Add

Brochure: RBSiC Rollers (interactive)

for Calcination of Cathode Active Materials (CAM)

Add

Downloads

2 Files online