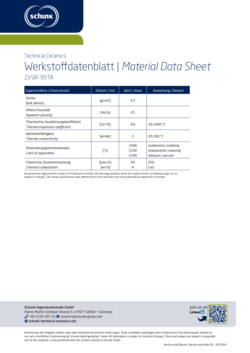

Material Data Sheet for ZirSIK-95TA

Zirconium Oxide

Zirconium oxide (PSZ; at Schunk ZirSIK-95 TA), is a frequently used oxide ceramic that has proven itself as a universal construction material in many industries. Thanks to its high thermal, chemical-corrosive and mechanical stability as well as its excellent thermal shock resistance, zirconium oxide can withstand even the highest loads.

What distinguishes ZirSIK-95 TA?

Zirconia ceramics from Schunk are characterized by high wear resistance in addition to good thermal shock resistance. Our ceramics are not wetted by molten metals, especially gold and platinum. We offer calcium-stabilized and yttrium-stabilized ceramics for thermal applications.

Where is zirconia ceramic used?

Due to their excellent thermal shock and temperature resistance, isostatically pressed or rammed ZirSIK crucibles are the first choice when it comes to the inductive melting of precious metals (especially platinum). The high product quality helps minimize crucible interactions with the melting material and enables long service lives.

ZirSIK-95TA is also used for groove/spring bricks and cooling ring bricks for lining quartz glass furnaces. There, the material's good thermal insulation properties at very high temperatures (> 1,700 °C) come into play. In addition, ZirSIK-95TA is used in the form of segment plates as kiln furniture for very reactive kiln furniture (e.g. for piezoceramics, powder metallurgical components).

Special properties of zirconium oxide:

- Low thermal conductivity (2.5 to 3 W/mK)

- High fracture toughness (6.5 to 8 MPam1/2)

- Oxygen ion conductivity

- High strength

- Wear resistance

- High fracture toughness