Automated Charging for Electric Port Vehicles

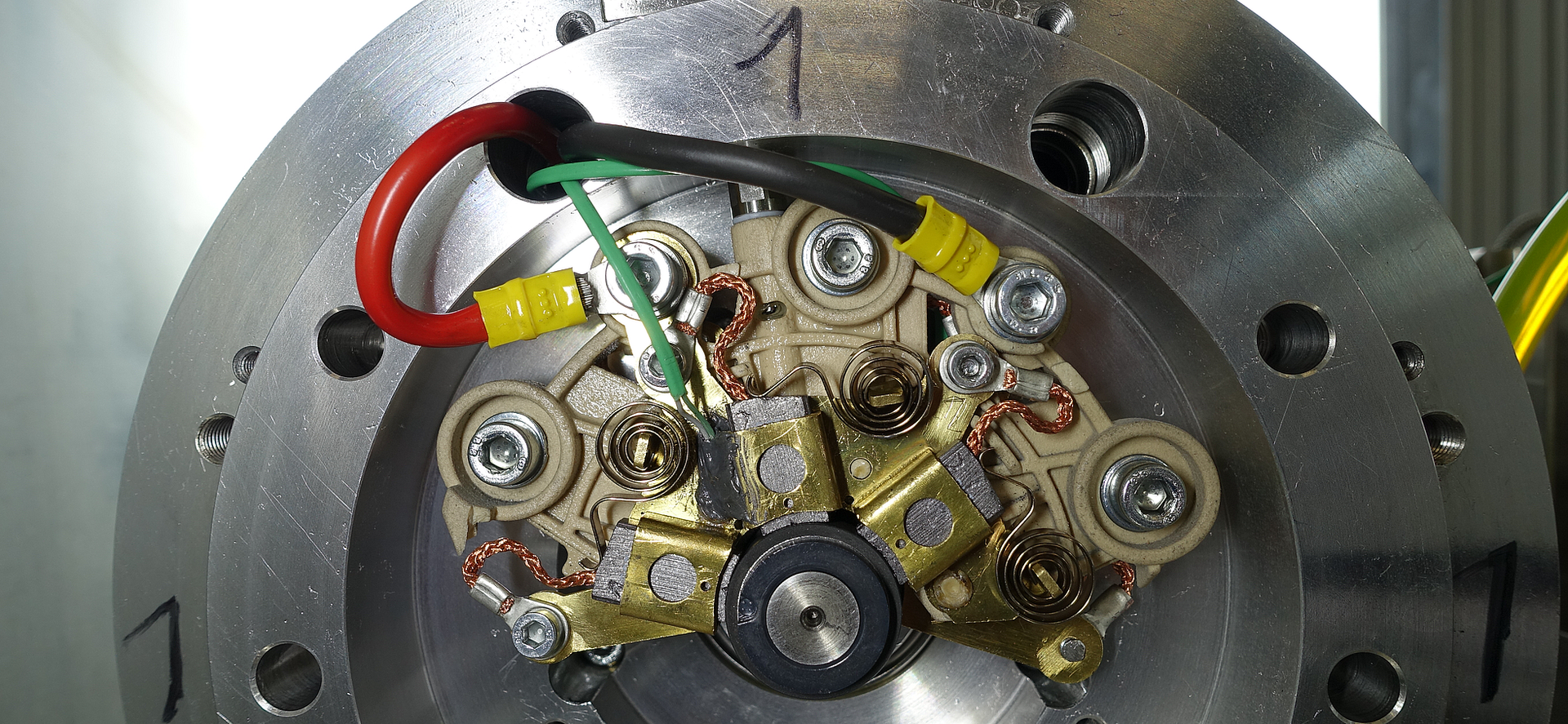

At Pier 400 in the Port of Los Angeles, one of the world’s busiest container terminals, a new high-performance charging system is now in daily use. In collaboration with Kalmar and APM Terminals, Schunk Transit Systems has implemented two Inverted Pantographs SLS201.401 to support the first fully electric straddle carriers in North America. The system enables automated, high-current charging (up to 1,200A)—ideal for demanding port environments with tight schedules and continuous operation.

Technical Deployment: Charging Cycles, System Capacity and Mechanical Design

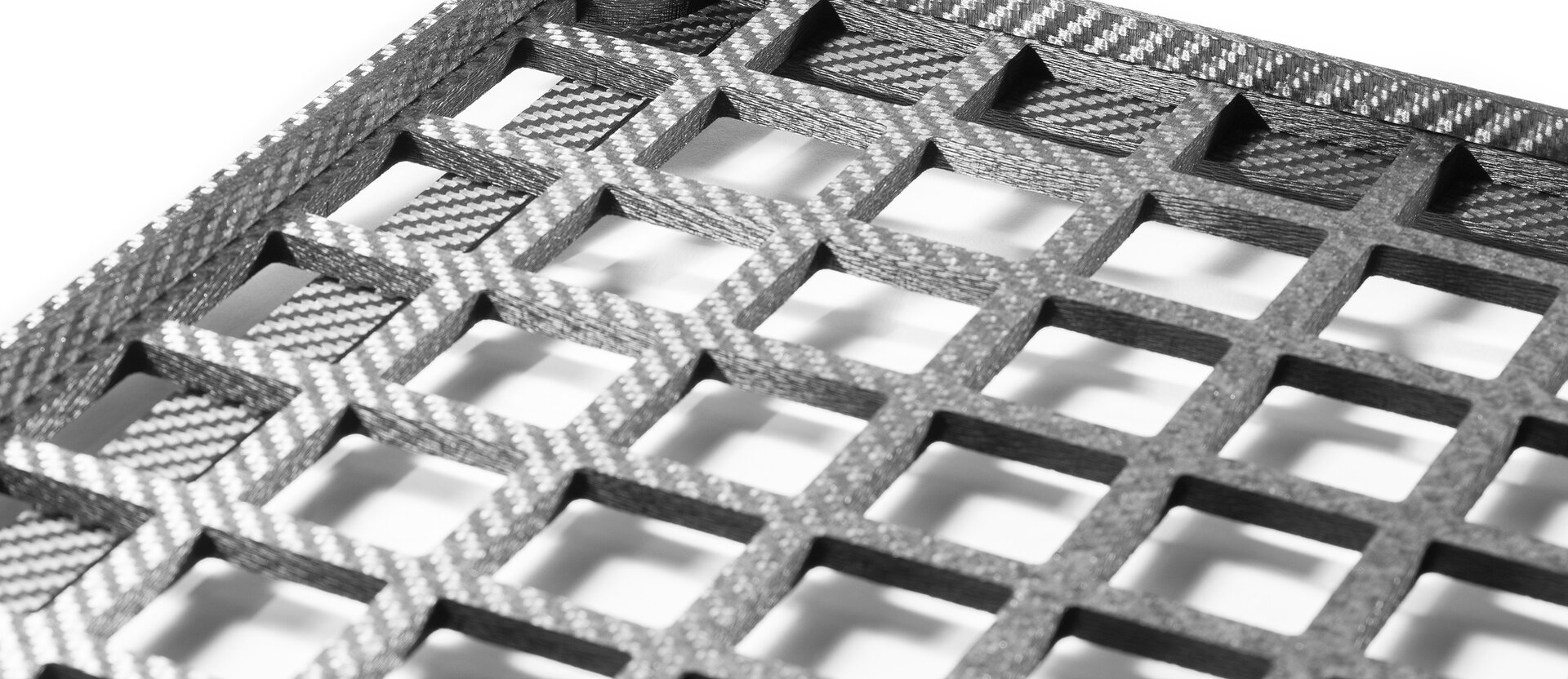

More than 100 charging operations per day are handled by the two SLS201.401 systems installed at the terminal. The infrastructure is designed for 24/7 use and optimized for durability and minimal maintenance. Key technical features include:

Thanks to its robust mechanical design, the system withstands dust, and weather exposure like salty air – ideal for outdoor marine terminal environments.

Benefits of the Inverted Pantograph in Port Logistics

The inverted design offers critical operational and engineering advantages over conventional plug-based or onboard charging solutions:

This makes the SLS201.401 a preferred choice for ports looking to electrify terminal vehicles without compromising operational performance.

Energy Savings and Emissions Reduction

Each all-electric straddle carrier saves approximately 125 metric tons of CO₂ per year compared to diesel-powered models. In addition to reducing the carbon footprint, the system eliminates tailpipe emissions, including nitrogen oxides and fine particulates—resulting in cleaner air for terminal workers and surrounding communities.

This deployment supports APM Terminals’ broader sustainability target: to achieve net zero operations by 2030. Smart charging technology is a key enabler on that path.

For all technical details on the inverted pantograph SLS 201.401 – from application areas and performance data to safety features – please see our compact data sheet:

Download now!

Scalable Smart Charging Infrastructure for Ports

The system is modular and scalable, allowing future expansion of charging points without vehicle modifications. The pantograph integrates with standard fleet management and terminal control systems, enabling seamless fleet electrification.

The SLS201.401 offers a technically mature, field-tested, and fully automated solution for ports seeking to decarbonize container handling operations. The technology is adaptable to other terminal vehicles such as reach stackers, terminal tractors, and AGVs.

Conclusion: Reliable Charging Technology for Zero-Emission Cargo Handling

The implementation of Schunk’s inverted pantograph at Pier 400 marks a major step forward for electric cargo handling in North America. It proves that automated, high-frequency charging is technically viable in high-throughput port environments. Together with partners Kalmar and APM Terminals, Schunk is enabling the transition to emission-free port logistics—with reliable charging systems built for industrial performance.

Interested in more information? Find all relevant brochures and documents on the topic of Automated Charging:

Download now!