Why Silicon Carbide Is Gaining Ground in Aerospace

Space is a tough environment. Satellite components must withstand extreme temperature changes, vibrations during launch, and function reliably for years without maintenance. This is where silicon carbide (SiC) shows its strengths.

It offers low density, high stiffness, and remains thermally stable under changing conditions. Silicon carbide can also be processed to achieve highly precise optical surfaces, making it the ideal material for applications like satellite mirrors and structural parts in optical systems.

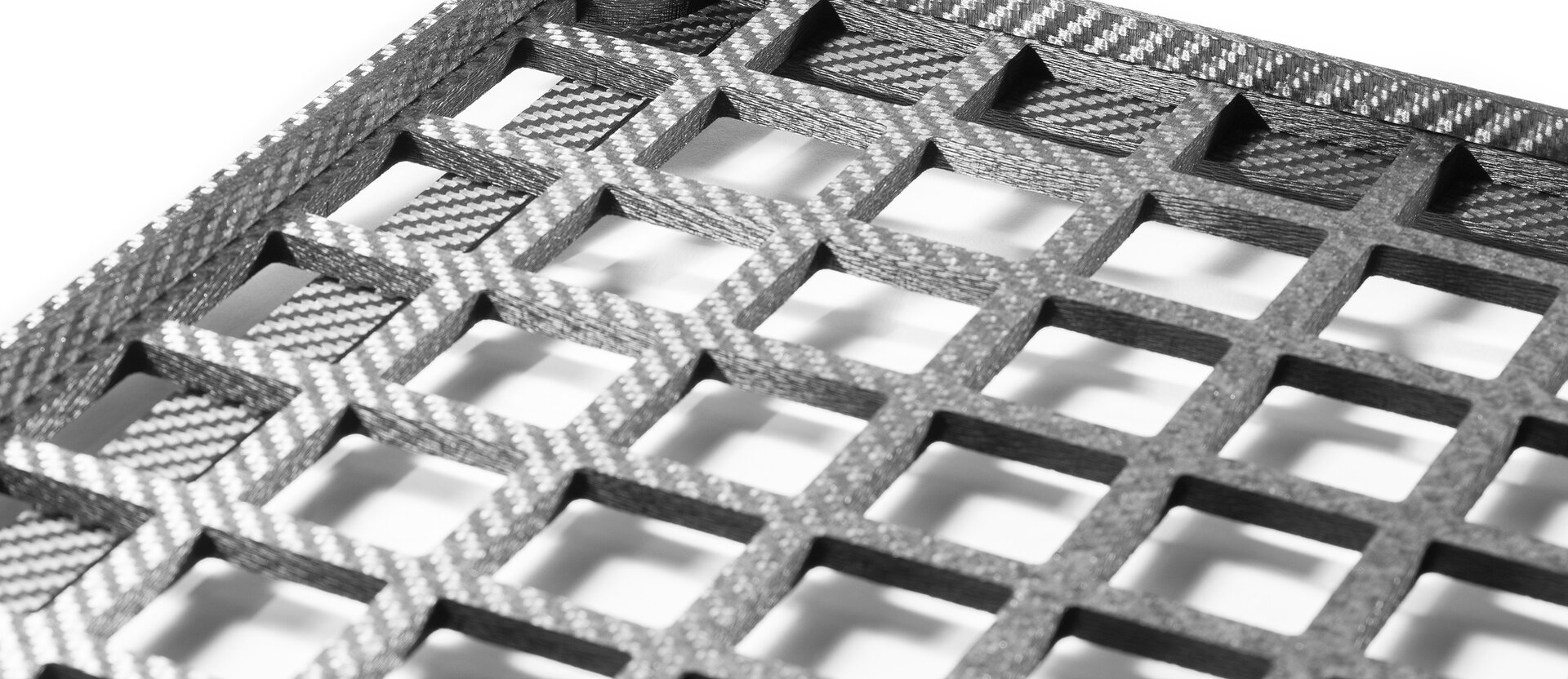

Design Freedom Meets Precision: The Advantage of Ceramic 3D Printing

Using its proprietary IntrinSiC® 3D printing technology, Schunk can produce large and complex ceramic components with exceptional precision. This approach offers:

- Greater design flexibility

- Weight reduction, which helps lower launch costs

- Shorter development cycles with consistent quality

Schunk is currently collaborating with a leading European space company on mirror substrates up to 1.55 meters in diameter. A prototype has already been manufactured for the European Space Agency (ESA).

In-House Expertise Across the Full Manufacturing Chain

One of Schunk’s key strengths is its fully integrated value chain. All critical steps – from raw materials to final finishing – are handled within the Schunk Group:

- Powder production at ESK-SiC

- 3D printing at Schunk Ingenieurkeramik (SIK)

- CVD SiC coating at Schunk Carbon Technology (SKT)

- High-precision polishing using OptoTech systems

- Cleanroom conditions provided by Weiss Technik

- Optical coatings supported by partners such as Dynavac

This tight integration ensures short lead times, consistent quality, and process reliability – all critical factors in aerospace manufacturing.

For the Next Generation of Optical Systems in Space

Schunk’s 3D-printed ceramic components are ideal for space-based systems where performance, reliability, and low mass are essential – including:

- Satellite mirrors for optical and infrared applications

- Support structures for sensors and instruments

- Lightweight components for scientific and defense missions

Combining advanced ceramic materials with additive manufacturing opens new possibilities for performance-optimized designs that meet the stringent demands of space missions.

Conclusion: Precision and Innovation for the Demands of Space

Modern satellite systems rely on components that are as smart as they are resilient – lightweight, stable, and precise. Schunk Technical Ceramics combines deep expertise in technical ceramics with advanced 3D printing and an integrated production approach to deliver solutions tailored for orbit.

From Willich to space – engineered for performance, built to last.

Interested in learning more? Discover our brochures and technical documents on advanced ceramic components and 3D printing solutions for space applications.

Download now!