Satellite components from the printer ensure optimum performance on the way intospace

3D printing enables highly complex satellite components

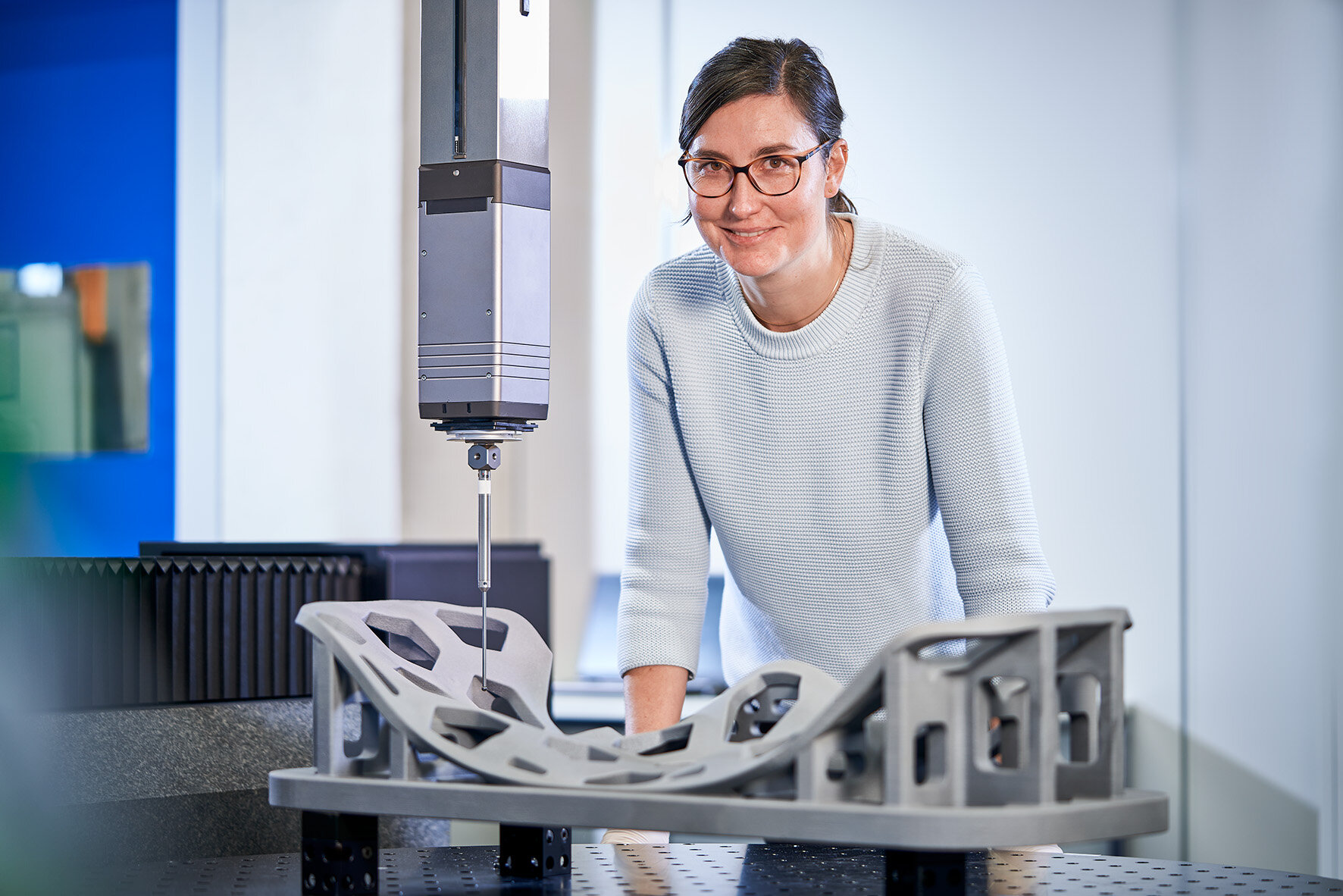

Clara Minas-Payamyar, Head of Development for Additive Manufacturing, and her team are driving forward the development of satellite components, among other things. The focus is on the Schunk material IntrinSiC®, a 3D-printed, reaction-bonded silicon carbide that is revolutionizing the production of complex components.

Aerospace industry faces major challenges

IntrinSiC® meets the highest requirements of the space industry

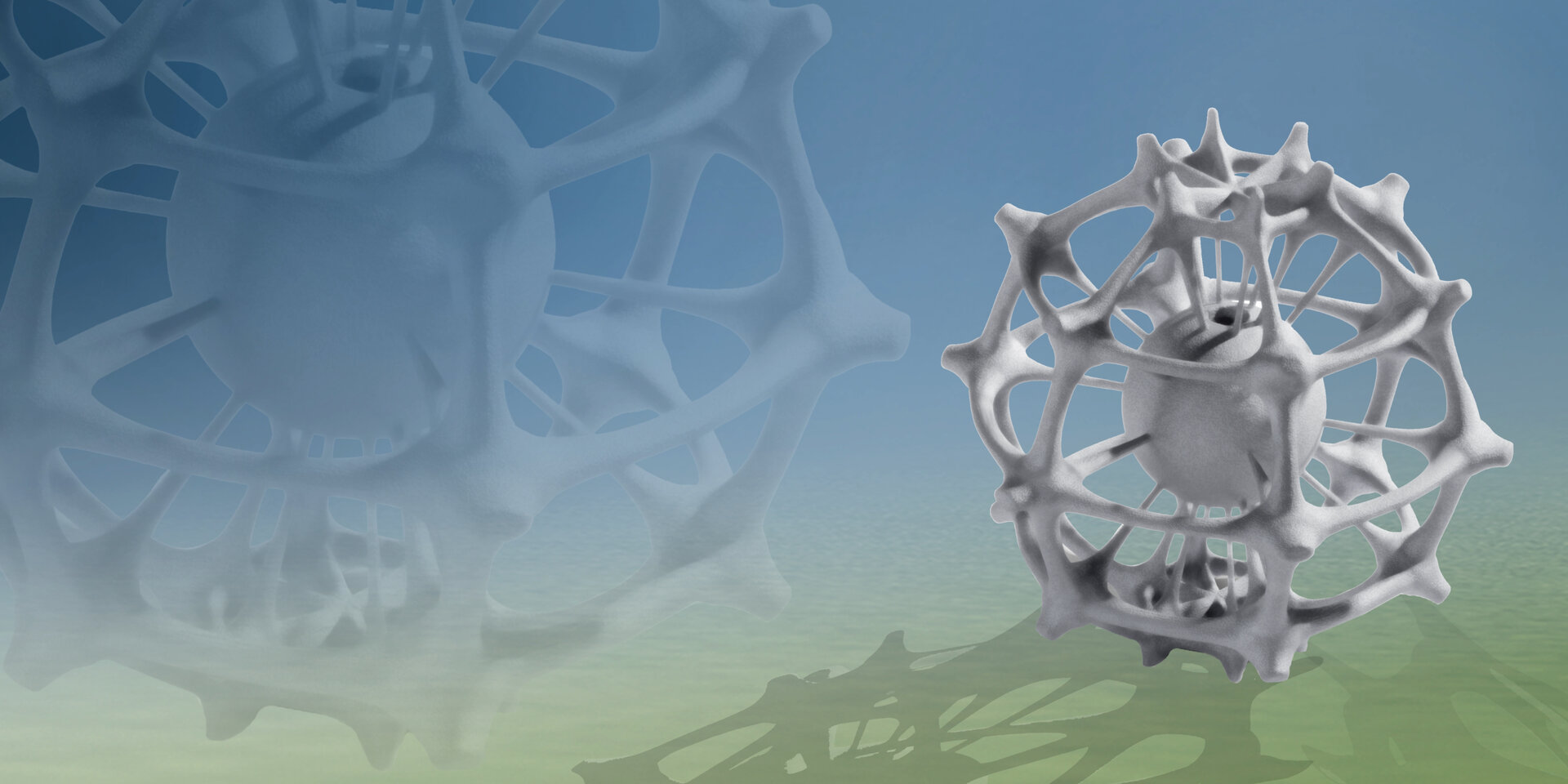

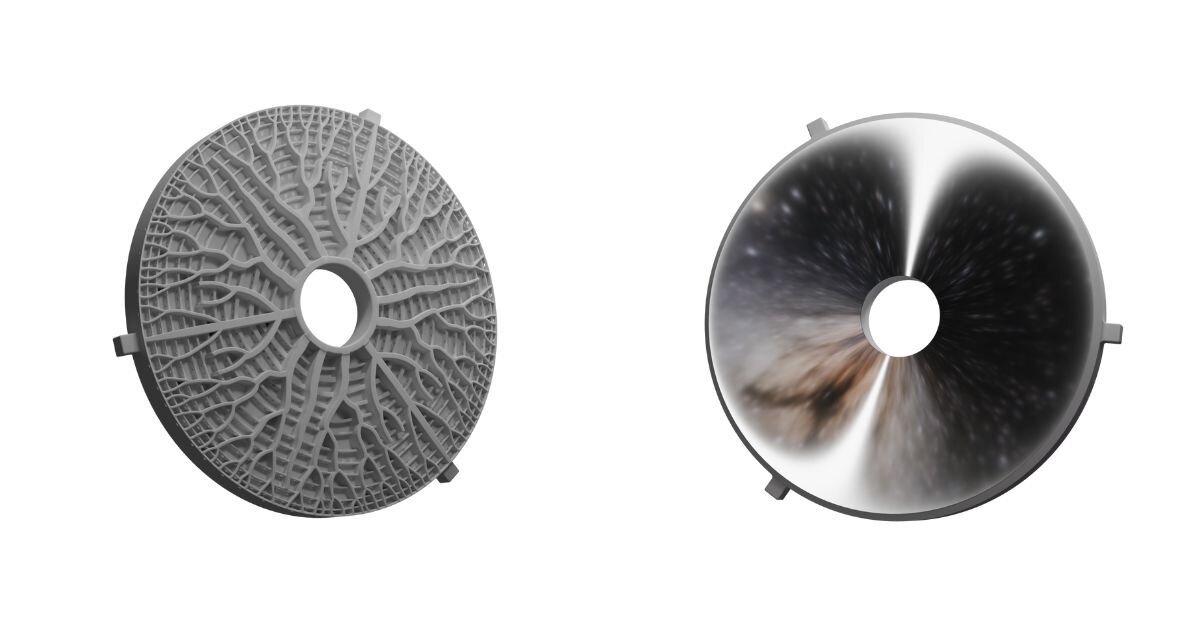

With IntrinSiC®, Schunk has developed a 3D printing process that can be used to manufacture components from reaction-bonded silicon carbide. This lightweight but almost diamond-hard material is now used in a range of high-tech applications. The material is predestined for use under the extreme conditions in space: Due to its special material properties, IntrinSiC® meets the high quality and cleanliness requirements of the space industry.

Lucrative process even for small quantities

"3D printing gives our customers a freedom of design that cannot be achieved with conventional manufacturing processes. This means that we can increasingly develop components with a focus on their performance and no longer on their manufacturability. It is also possible to produce very complex components with short lead times. Even the production of small quantities, which is typical in the aerospace industry, is lucrative with IntrinSiC®"

Less weight, lower costs - 3D printing makes it possible

IntrinSiC® also offers potential savings in terms of weight: "With bionic designs, the weight of components can be greatly reduced," explains Minas-Payamyar. "We can also simplify complex component systems by combining them into one component. The result is fewer interfaces, which saves component integration time and costs."

3D printing as a pioneering technology for the aerospace industry

Minas-Payamyar sees great potential for the future in IntrinSiC®: "I see our process as an enabler for new types of satellite systems. If the design freedom of additive manufacturing is already taken into account in the initial design phase of satellites in the future, the possibilities of 3D printing can be fully exploited."

→ Here you can download the IntrinSiC 3D printing and Machanical Engineering brochures!