Introduction: Saving Energy in High-Temperature Processes

In industrial heat treatment—such as hardening, sintering, or brazing—energy consumption and process stability are critical performance factors. Workpiece carriers and charging systems significantly influence both. While traditional steel designs often hinder efficiency due to their weight and limited thermal resistance, carbon fiber-reinforced carbon (CFC) charging fixtures offer a proven way to reduce energy input and improve overall process performance.

Energy Savings with CFC Fixtures

Steel fixtures have a high thermal mass. Every cycle requires the full mass to be heated up and cooled down again, extending process times and increasing energy consumption. Steel also acts as a thermal sink in the furnace—absorbing heat, releasing it slowly, and disrupting temperature uniformity.

CFC fixtures are up to 70 percent lighter and have significantly lower heat capacity. This reduces the amount of material that needs to be heated with each cycle. As a result, heating and cooling phases are shorter, and the specific energy demand per batch is substantially lower.

In real-world operations, users report that replacing heavy steel fixtures with significantly lighter CFC systems has led to measurable increases in load capacity and overall throughput—while reducing the energy consumption per treated part.

Our experts note that many customers have achieved up to 20 percent higher productivity along with notable energy savings by switching to CFC systems.

Comparison: Steel vs. CFC in Heat Treatment Processes

|

Criteria

|

Steel Fixtures

|

CFC Fixtures (Schunk)

|

|

Thermal Mass

|

High – must be fully heated in every cycle

|

Low – significantly reduces energy demand per cycle

|

|

Weight

|

Heavy – limits load capacity and extends cycle time

|

Up to 70% lighter – enables higher net load

|

|

Thermal Stability

|

Prone to deformation above approx. 800 °C

|

Stable up to 2,000 °C depending on design

|

|

Cycle Time

|

Long – due to slow heating and cooling

|

Short – enables faster temperature transitions

|

|

Energy Consumption

|

High – due to mass and poor thermal dynamics

|

Reduced – lower thermal mass and faster response

|

|

Automation

|

Limited – dimensional changes over time

|

Precision-fit – suitable for robotic handling

|

|

Service Life

|

Limited – requires regular repair or replacement

|

Long-lasting – low maintenance, highly durable

|

|

CO₂ Footprint

|

Higher – due to energy use and replacement frequency

|

Lower – due to efficiency and longevity

|

These differences translate into measurable efficiency gains—especially in energy-intensive heat treatment environments. Moreover, the streamlined, material-saving design of CFC fixtures often allows for a greater number of parts per batch—an additional factor that boosts cost-efficiency.

Stable Processes at High Temperatures with CFC Fixtures

Beyond weight, temperature resistance is a key performance indicator. Steel loses mechanical stability above roughly 800 °C, often leading to distortion of the carrier structure and uneven heat distribution. To compensate, operators are forced to apply energy-intensive process adjustments.

CFC fixtures, in contrast, maintain dimensional stability above 1,000 °C. Thanks to reinforced fiber construction and design optimization, they can be used at process temperatures up to 2,000 °C without permanent deformation. This enables precise positioning of workpieces, uniform treatment conditions, and improved energy utilization.

Shorter Cycle Times – Lower Energy Use with CFC Systems

The low weight of CFC charging systems doesn’t just reduce energy demand—it also shortens cycle duration. Both heating and cooling phases are accelerated, allowing more batches per shift and lowering energy use per part.

This leads to improved furnace utilization and a better specific energy footprint—making CFC fixtures a powerful lever for lowering production costs.

Less Maintenance, Longer Service Life

Steel charging fixtures are prone to warping, cracking, oxidation, and scale formation at high temperatures. These issues impact energy efficiency, increase maintenance needs, and often lead to unplanned downtime.

CFC materials are inherently resistant to thermal shock, creep, and corrosion. Charging fixtures retain their mechanical integrity over hundreds of furnace cycles—without reworking or repair. And because all materials are manufactured in-house at Schunk, customers benefit from secure supply chains and consistently high quality.

Energy-Efficient Design with Schunk CFC Systems

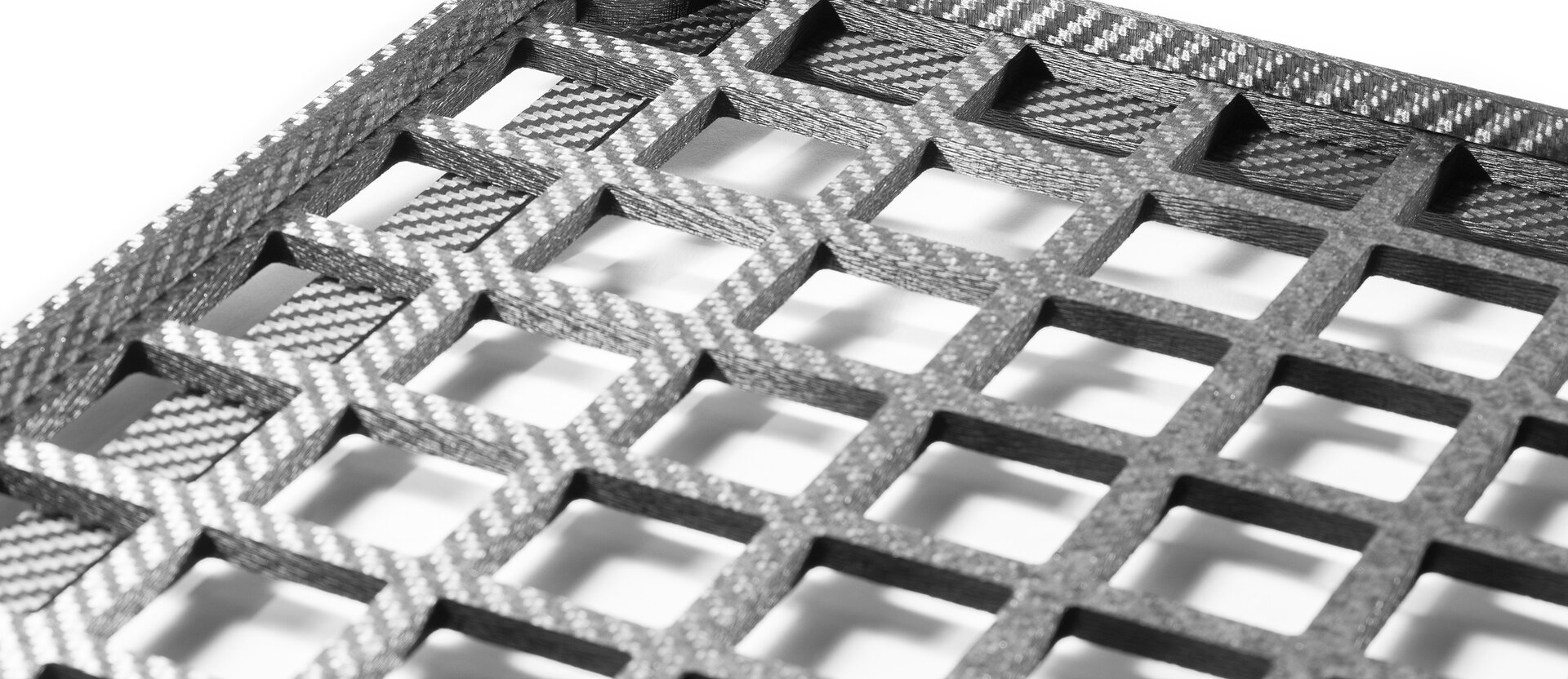

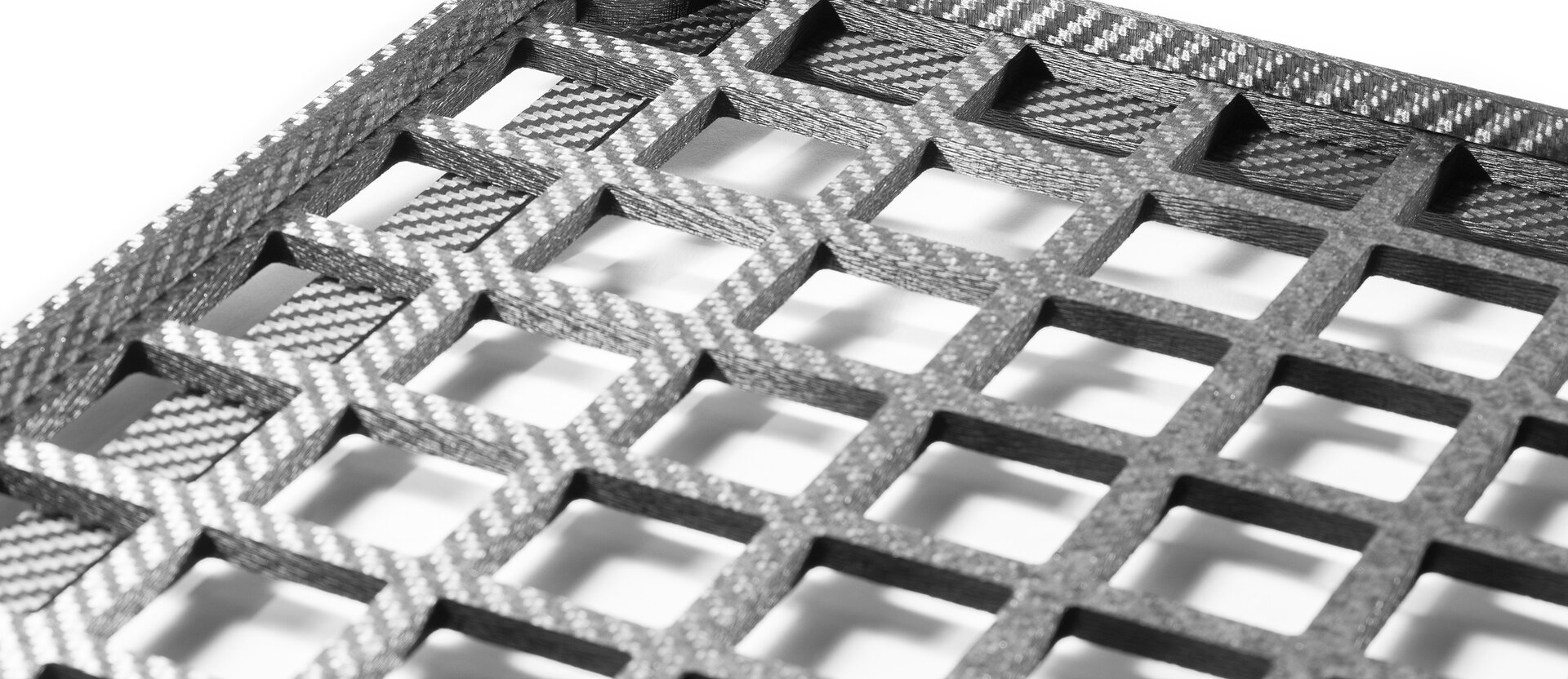

Schunk develops charging systems specifically for energy optimization. Using FEM simulations, we determine the optimal balance between structural strength and low mass as early as the design phase.

Our modular UniGrid® platform combines high rigidity with minimized thermal mass. Protective components such as CarboGard® and Durafox® prevent unwanted contact reactions, ensuring process integrity even above 1,050 °C.

We support customers across the entire lifecycle—from technical consulting and design to after-sales service. The goal: reliable and energy-efficient heat treatment with carbon fiber-reinforced carbon technology.

Conclusion: Less Energy per Batch – Greater Efficiency with CFC Fixtures

Carbon fiber-reinforced carbon (CFC) charging fixtures demonstrably reduce energy consumption in industrial heat treatment. Their low thermal mass, high temperature stability, and long service life improve process reliability, system efficiency, and the CO₂ balance of manufacturing operations.

In energy-intensive industries such as metal processing, powder metallurgy, or aerospace, CFC workpiece carriers are a key building block for sustainable and resource-efficient production.

With platform solutions like UniGrid®, CarboGard®, Durafire®, and Durafox®, Schunk offers a well-engineered portfolio tailored to the needs of high-temperature, energy-optimized heat treatment environments—supporting lower energy input per part and stronger overall performance.

Interested in more information? Find all relevant brochures and technical documents on energy-efficient heat treatment with carbon charging racks.

Download now!