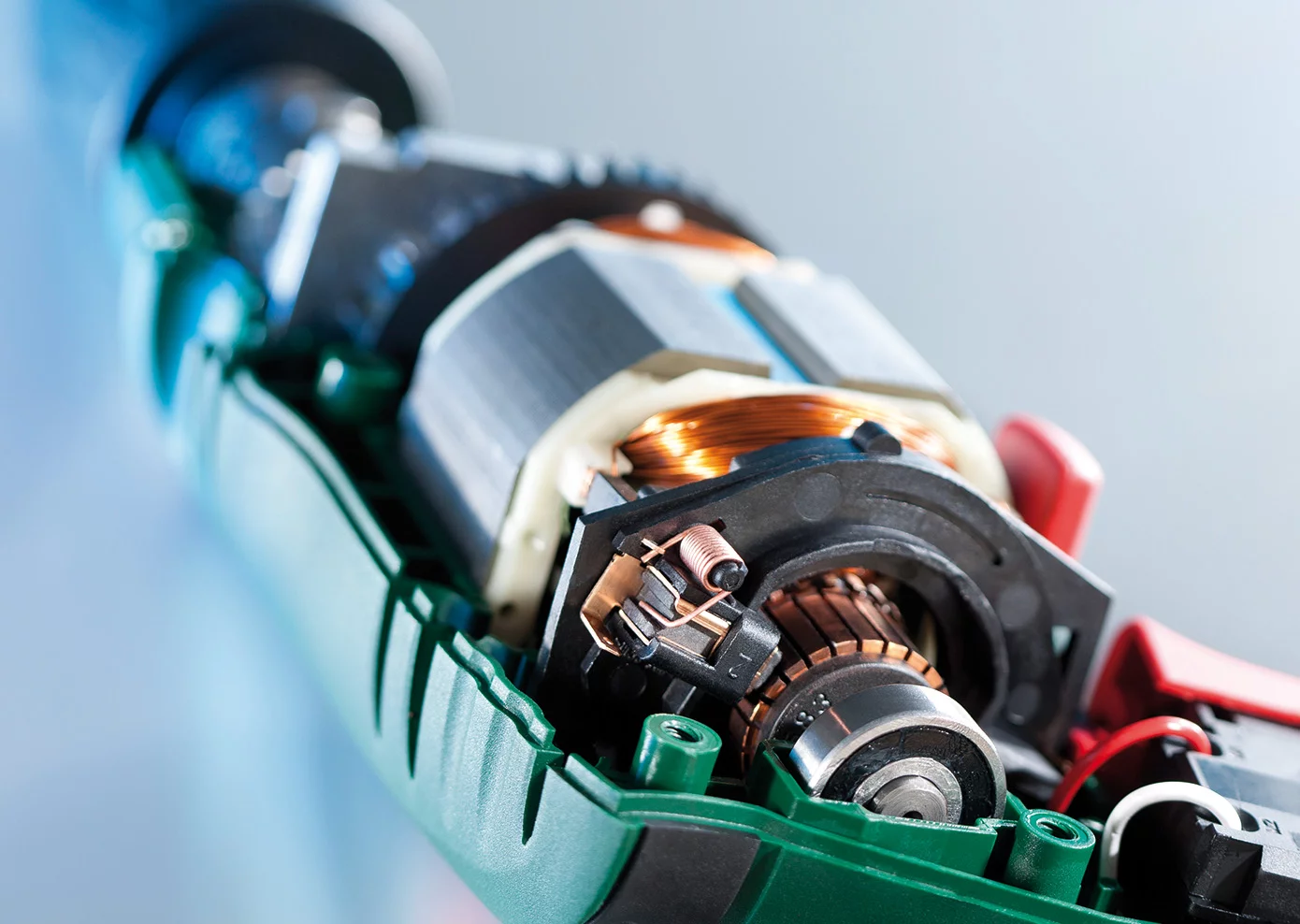

industrial motors and mass transit technology

Schunk offers:

- In-house material development tailored exactly to your needs

- Carbon brushes with excellent contact quality for power and signal transmission

- Materials with high resistance to chemicals, temperature, and abrasion

- Products with long service life and reduced maintenance requirements

- Technical consulting and adaptation to individual systems

Order Guide: Carbon Brushes

Add

Physical Data: Carbon Brushes

for industrial and railway applications

Add

Recommendations: Carbon Brushes

for industrial and railway applications

Add

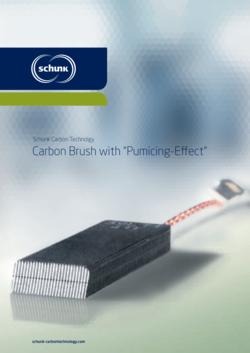

Brochure: Carbon Brush - Pumicing Effect

Avoid the Conventional Pumicing Process with Schunk Carbon Brushes

Add

Downloads

4 Files online