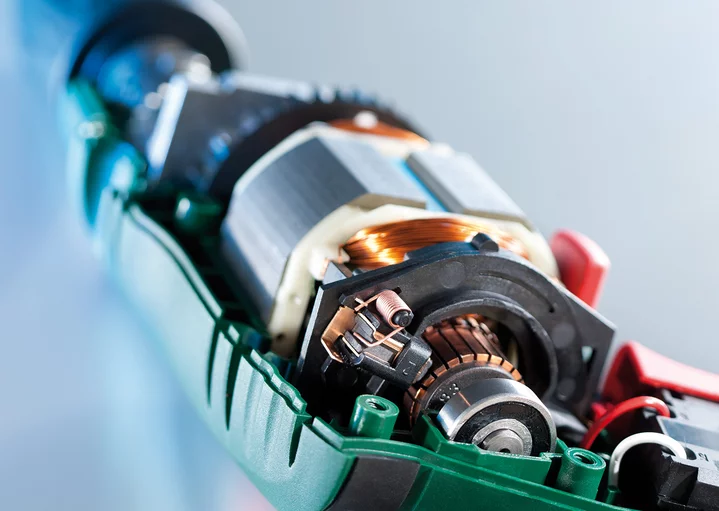

industrial motors and mass transit technology

Typical requirements for carbon brushes:

- Load change resistance

- Low wear of brushes and counter material

- Adaptation to individual motor parameters

- Secure current transmission

This results in maximum safety in motor operation – reliable and long-lasting.

Order Guide: Carbon Brushes

Add

Catalogue: Carbon Brush Holders - Electric Machines

versions, variants and types

Add

Brochure: Current Transmission

Schunk Industry - Your Partner in Industrial Power & Signal Transmission

Add

Physical Data: Carbon Brushes

for industrial and railway applications

Add

Recommendations: Carbon Brushes

for industrial and railway applications

Add

Brochure: Signaling Devices

Signaling Devices made by Schunk - Premium Equipment for Professional Electric Power Tools

Add

Brochure: Mining

Optimal Mining Equipment Performance with Carbon

Add

Brochure: Carbon Brush - Pumicing Effect

Avoid the Conventional Pumicing Process with Schunk Carbon Brushes

Add

Brochure: Carbon Brush with Cut-Off & Signaling Device

Reliability for Professionals –

Carbon Brushes with Cut-off Device

and Signaling Device

Add

Downloads

9 Files online