Components for efficiency and safety – from Schunk

Your Advantages with Schunk Components

Partnering with Schunk means benefiting from:

- Maximum thermal resistance: Components designed for process temperatures exceeding 2000 °C – essential for methane pyrolysis.

- Outstanding durability: Reduced maintenance and lower operating costs – ideal for continuous operation.

- Customized solutions: Tailor-made components designed specifically for your pyrolysis system.

- Global availability & support: Worldwide delivery with expert technical consulting.

- Sustainable hydrogen production: Enabling cleaner energy and climate protection.

- Proven technology & industry experience: Schunk is an established partner in methane pyrolysis, working with leading companies and offering deep technical expertise for your project.

Brochure: Methane Pyrolysis

Add

Downloads

1 Files online

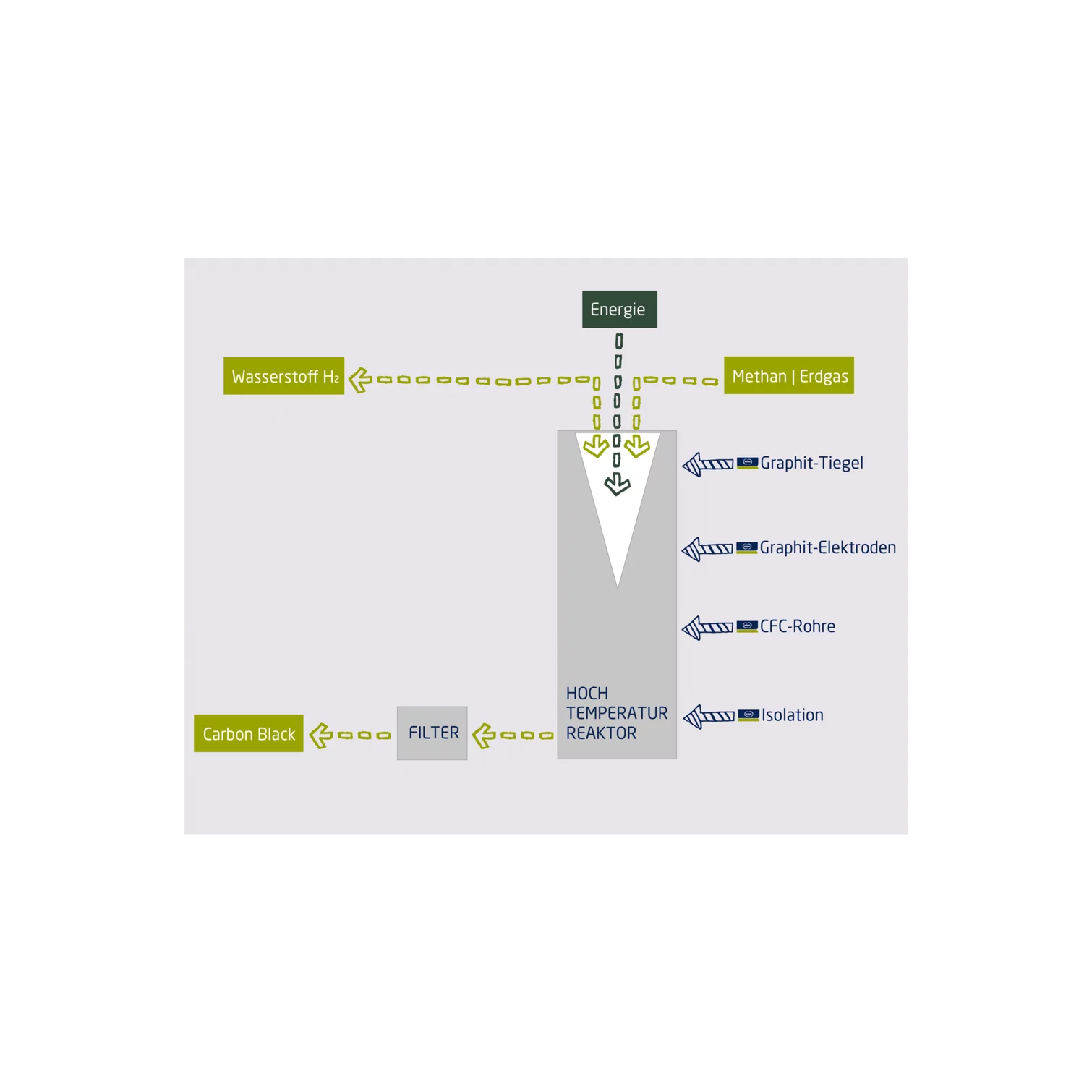

Process Overview of Methane Pyrolysis

Maximum efficiency for your processes – with the right combination of materials and coatings

Key Benefits at a Glance

• Reduced downtime and maintenance costs

• Enhanced efficiency through surface optimization

• Customized coatings tailored to your specific process needs

The right combination of material and coating is critical to your plant’s performance – our experts are here to support you.

Materials & Coatings