For Fuel Cells and Redox Flow Batteries

The manufacturing process of bipolar plates

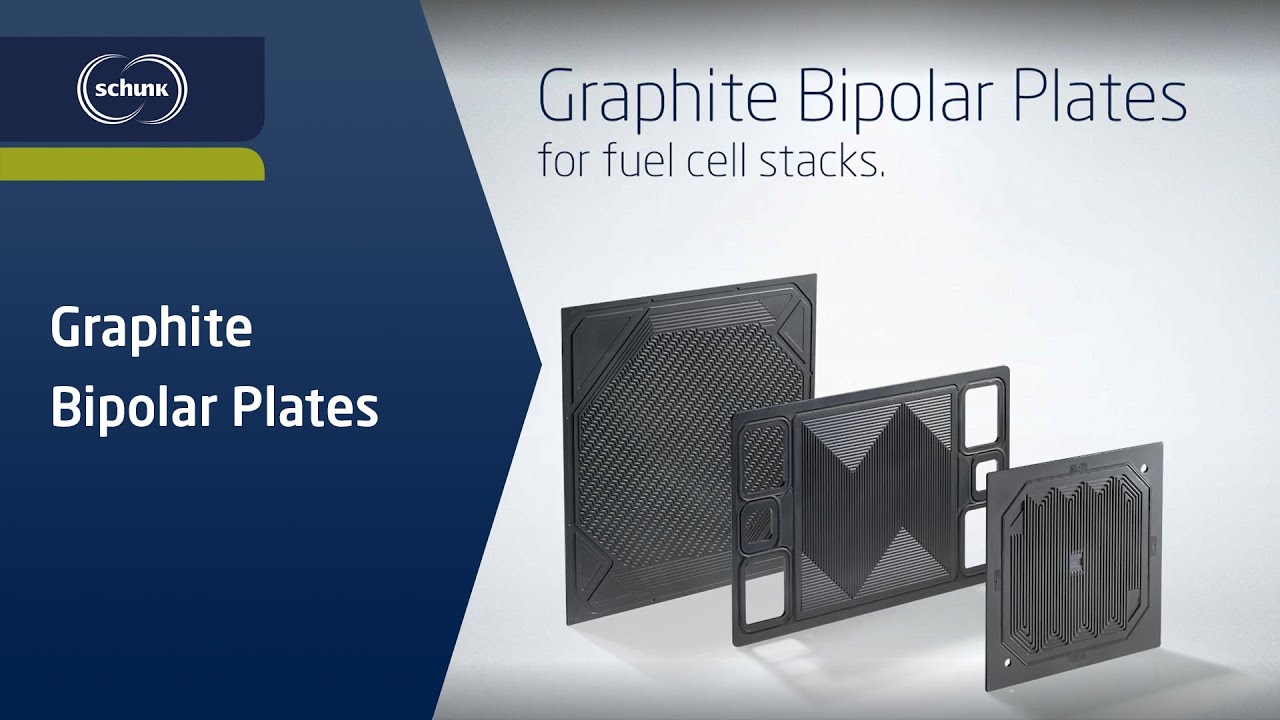

Graphitic bipolar plates are key components in the functioning of fuel cells and redox flow batteries. They make a significant contribution to the performance and efficiency of this "green" technology of the future. Compression-molded graphitic bipolar plates impress with their enormous degree of freedom in the design of the media-carrying structures and the sealing geometries. They also have excellent mechanical and electrical properties and a long service life. Extruded graphitic bipolar plates are flexible and can be manufactured in very large component dimensions.

How are molded and extruded graphitic bipolar plates manufactured?

The Schunk Group is already able to produce compression molded and extruded bipolar plates in large series. We take care of the entire process, from the procurement of raw materials and the shaping of the bipolar sheet to its final, customer-specific finishing.

How are bipolar sheets manufactured?

Bipolar sheets can be manufactured using both compression molding and extrusion processes. Which process is chosen for a specific application depends on the customer's requirements and the individual needs of the application.

From the inquiry to sampling and series production

Before we manufacture our bipolar plates in series according to your individual requirements, we receive a customer inquiry. This is followed by coordination of the initial ideas based on your drawings and requirements. We will then send you standard plates in the form of test samples on request. You can use these for initial functional evaluations, for example. Based on the findings of the sampling, we then manufacture functional prototypes, which are produced by milling a standard plate. Once the functional prototype has been sufficiently tested in your application, bipolar plates can be manufactured in series. Our state-of-the-art machinery and equipment is available for the precise and economical series production of bipolar plates.

Engineering competence in materials technology and machine building.

Downloads

Efficient manufacturing of bipolar plates

Molded bipolar plates

Schunk Kohlenstofftechnik has the entire value chain for the production of graphite bipolar plates under its own control. The composition of the material, the production technology and the finishing are closely coordinated and can be customized. This combination of material and manufacturing expertise is one of our great strengths.

Extruding bipolar plates with a high graphite fill level

The extrusion process also requires a special formulation of purchased raw materials such as graphite, carbon black and binders before production of the bipolar plates can begin. High-quality extruded foils for use as bipolar plates in redox flow batteries are characterized by a high graphite content.

Expert tip: The electrical, mechanical and thermal properties of a bipolar plate can be precisely adjusted by optimizing the formulation.

In the extrusion process, the high-performance material, which has a thermoplastic bond, is converted into a continuously produced film. This makes it possible to produce bipolar sheets in sizes that can exceed lengths of 1000 mm and widths of 380 mm. The film can be given additional properties through the application of surface modifications. The flexible, extruded bipolar plate can be welded directly to the frame of the battery stack, eliminating the need for conventional sealing solutions and resulting in an extremely compact design.

We explain the unique properties of bipolar plates and how they contribute to the efficiency and performance of fuel cells. We also show how our customers can benefit from using this technology.

Jens Völlner, Business Development Manager Fuel Cell Applications, about graphite bipolar plates - the key-component for fuel-cells.

Videos

Do you have any questions about our graphite bipolar plates?

The Schunk Group manufactures bipolar plates for use in fuel cells in series production and with outstanding quality. If you would like to see our expertise along the entire value chain for yourself, please contact our team of experts. We will be happy to advise you personally and send you samples of our bipolar plates on request.