Hot glass handling

Efficient hot glass handling – Innovative solutions for the glass industry

High temperatures, sensitive materials and the highest purity requirements: The glass industry demands safe and reliable solutions for handling hot glass. Schunk Group offers both standardized and tailor-made solutions that can be used along the entire production line. Benefit from our decades of experience in material, coating and processing technologies, as well as our in-depth application expertise, to ensure an efficient and smooth glass manufacturing process. Even the most challenging process step in hot glass handling becomes manageable with our advanced materials.

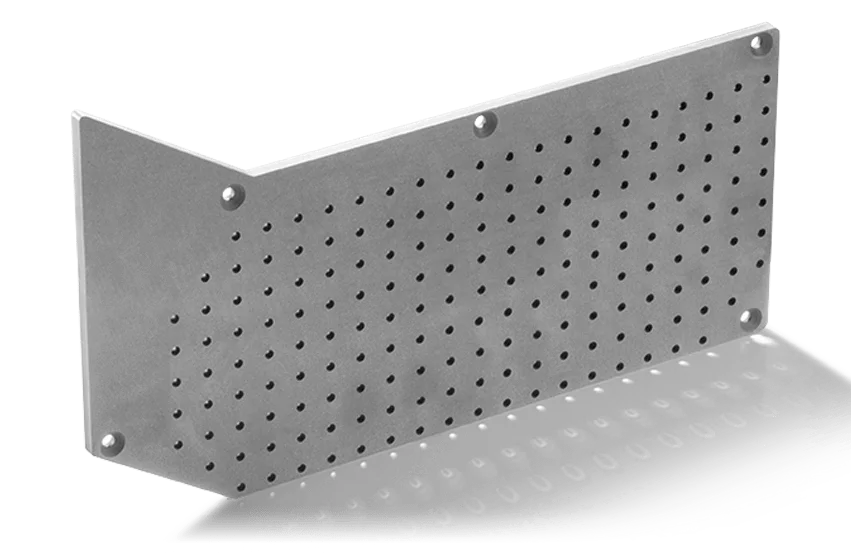

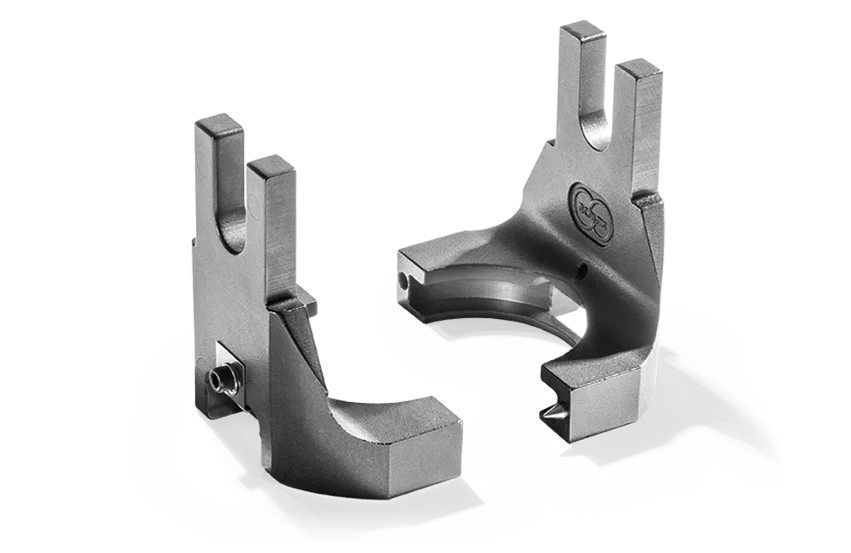

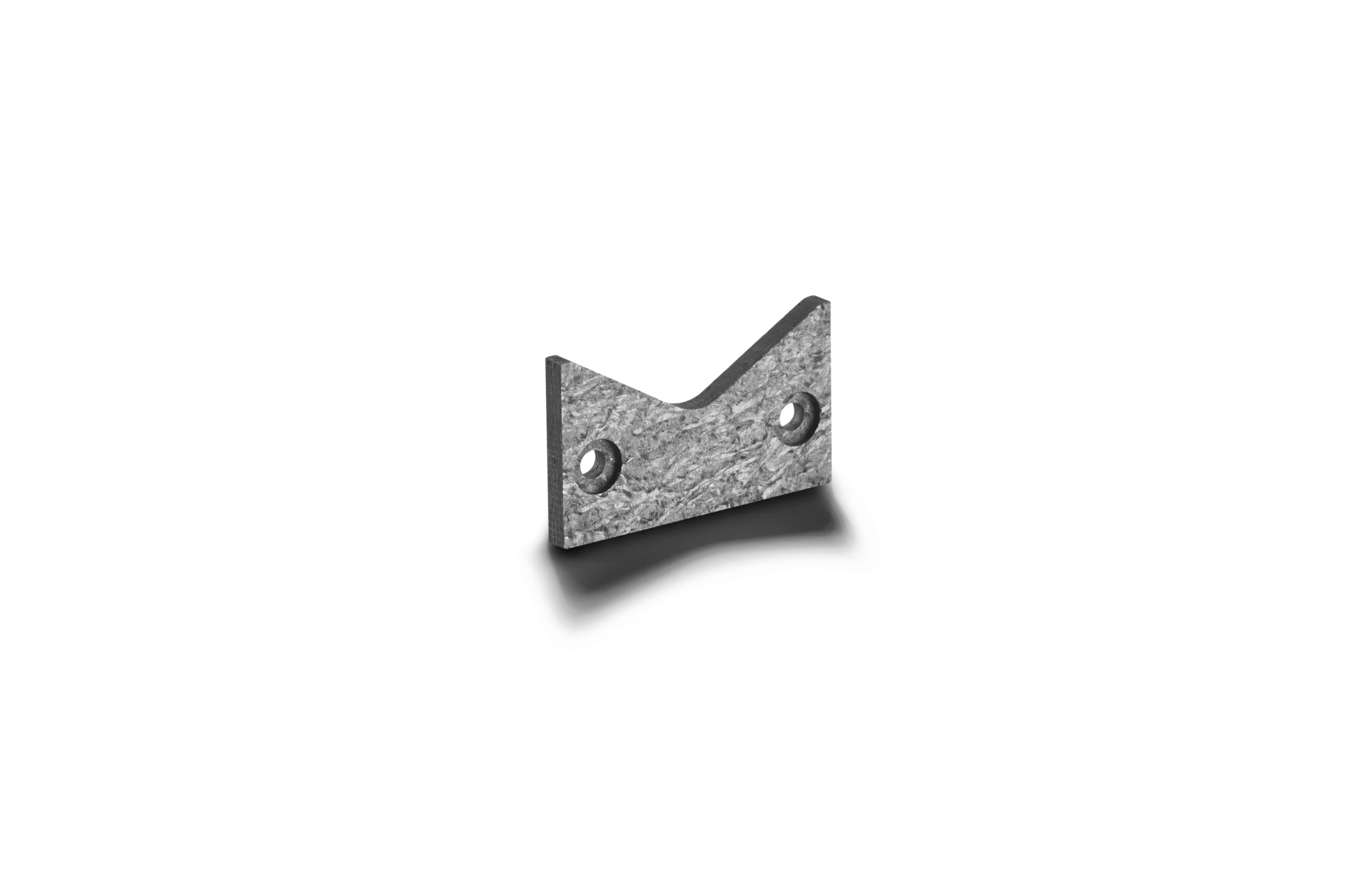

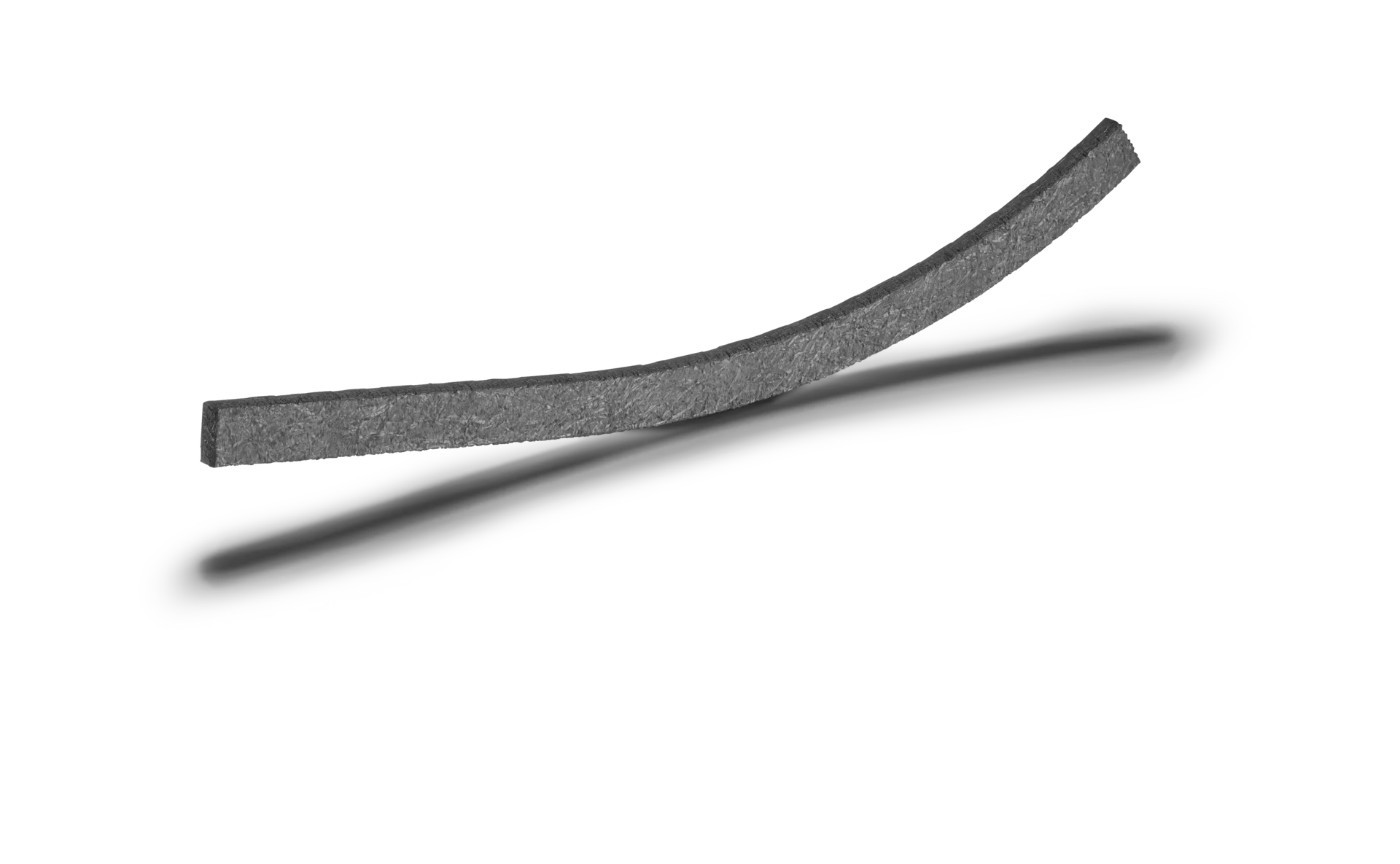

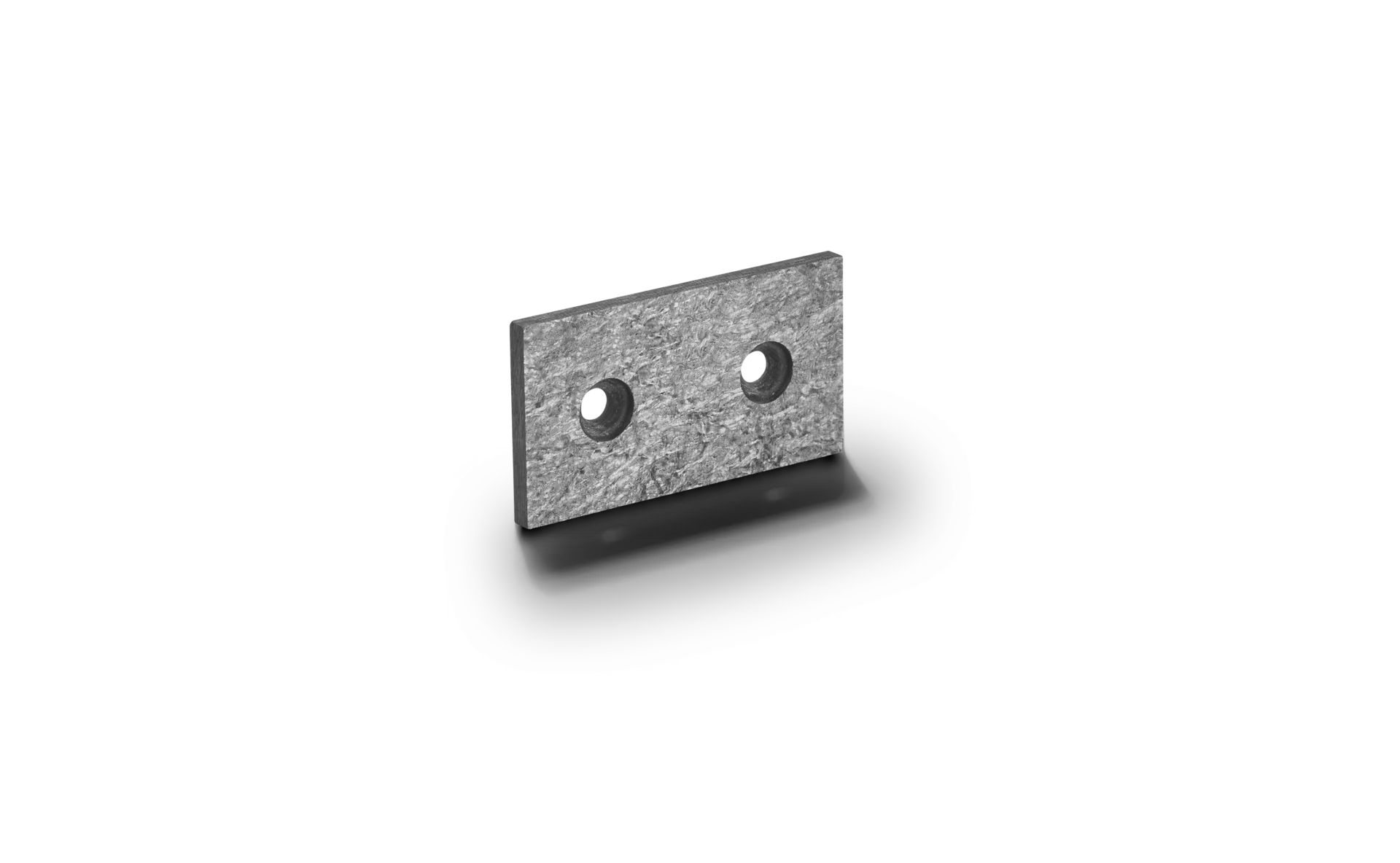

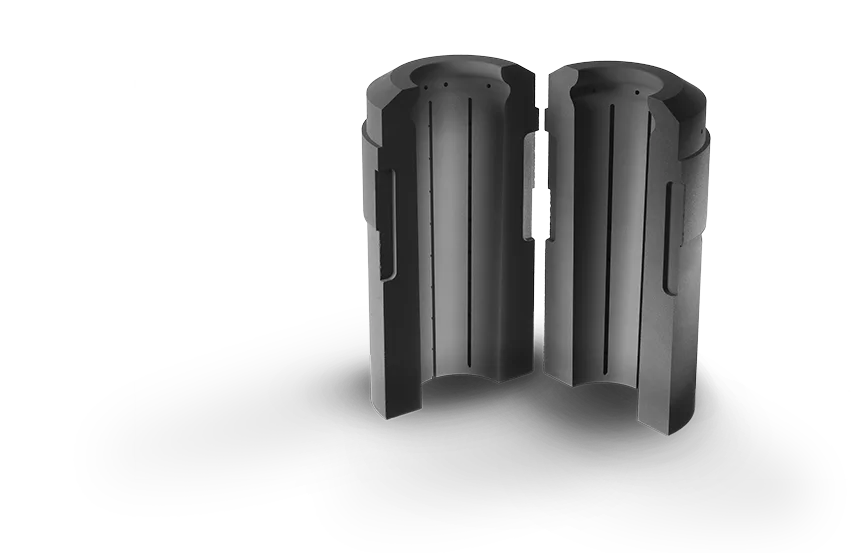

Specialized components for optimized hot glass processes

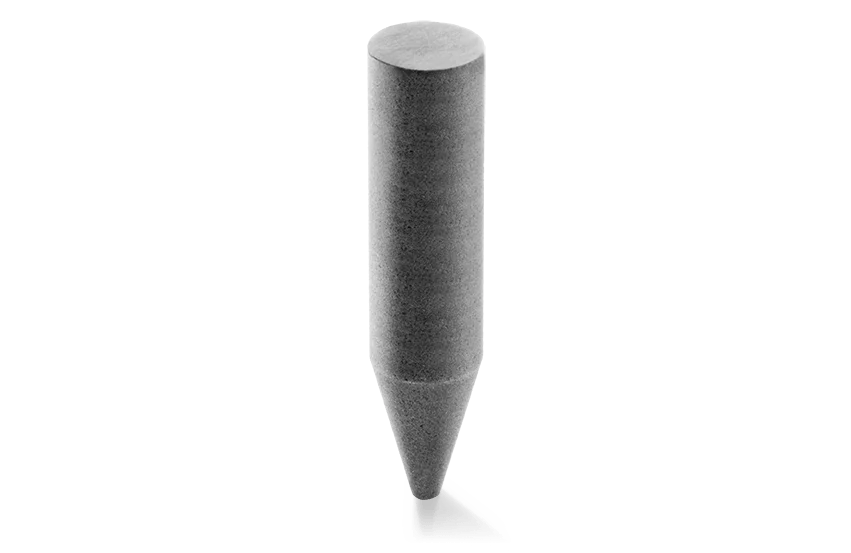

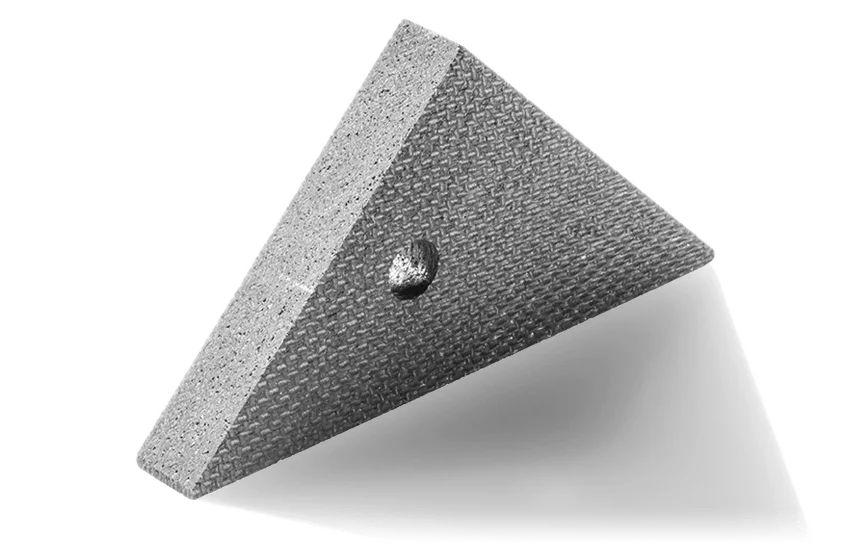

Our product solutions are designed to optimize every step of hot glass handling. This ensures stable processes and a high-quality surface finish. Our components made from high-purity carbon materials feature low thermal conductivity and minimal abrasion, protecting the purity of the glass. Stress cracks and unwanted deposits are effectively prevented. For components subject to extreme mechanical stress, we also offer carbon fiber-reinforced composites (CFC).

High-performance materials for reduced abrasion and stress cracks

When hot glass is cast, conveyed or guided, it inevitably comes into contact with other materials. Their surface properties determine whether scratches, cracks or deposits will occur. Choose Schunk to eliminate these risks and ensure trace-free handling. Two critical factors for a smooth production process and flawless glass quality are the functional reliability and surface characteristics of the contact materials. With our carbon components, you gain full control over both.

Free to download – our materials in comparison

From container glass to pharmaceutical glass

Innovative materials from the Schunk Group

The Schunk Group uses advanced materials such as Durafire® Glass, a carbon fiber-reinforced ceramic material with outstanding strength and oxidation resistance. This material is ideal for long production cycles, especially in container glass production, and allows you to benefit from longer service lives and reduced maintenance intervals.

No stress cracks

No residue or adhesion

Long service life

Customized solutions

CFC materials

Reliable support for smooth operations

In glass production, everything needs to run smoothly. To prevent unplanned downtime or process deviations, we offer a comprehensive service package that supports you quickly and reliably. We are familiar with the unique challenges of container glass, tubing glass, pharmaceutical glass and household glass production. Our service concept is built on this experience – giving you the confidence of a reliable and experienced partner.

Innovative Solutions for Thermal Applications

Schunk Industry: Leading the Way in Glass Handling

Downloads

Let us advise you

Contact us for innovative hot glass solutions - for optimum processes and maximum quality!