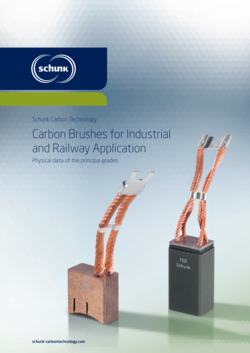

Schunk electrographite materials for electrical applications are characterized by very high purity. This results in optimum protection and very low wear of the counterface material. In addition, the materials can be adapted to the specific application conditions by post-treatment. Since we manufacture our own materials, you can rely on Schunk for a broad portfolio of die-pressed, iso-pressed, vibration-compressed and extruded materials, numerous finishing options and sound application engineering advice.

Where is our electrographite used?

Electrographites generally exhibit good sliding properties, have lower electrical resistance, high thermal conductivity, and improved corrosion resistance compared to non-graphite materials. The electrical and tribological properties are used for electrotechnical applications. The good film-forming properties, i.e. the ability to form a graphite layer on the mating material, are another important property of electrographite materials. Our materials are used, for example, in carbon brushes, shaft seals, dry-running dynamic seals, dry-running plain bearings and vanes in dry-running rotary vane pumps and compressors. Our carbon/carbon (C/C) solutions enable stresses to be dissipated and are virtually wear-free. Their very low electrical noise allows them to be used for signal and data transmission. Due to its high purity and good electrical and thermal conductivities, electrographite is also used in analytical and medical technology, e.g. as conductivity measuring electrodes (dialysis) or as a component in thermal analysis equipment.