Efficient, Robust, and Rare-Earth-Free: Schunk's Wet-Running Solution for EESM Motors

Improved range with the same battery, enhanced system robustness, and no reliance on critical raw materials – Schunk Mobility Carbon’s wet-running current transmission system for Externally Excited Synchronous Motors (EESMs) addresses key challenges in modern electric powertrain design.

The system, developed by a team at Schunk’s Bad Goisern site, is built to operate reliably in direct contact with cooling oil – a critical advantage for next-generation EVs.

EESM vs. PSM: Why Automakers Are Looking Beyond Magnets

While Permanent Magnet Synchronous Motors (PSMs) are still widely used in electric vehicles, EESMs are gaining attention as a sustainable and cost-effective alternative. They don’t require magnets, meaning they avoid the use of rare earth elements – a key factor in reducing supply chain risk and environmental impact.

However, one technical challenge remains: power transmission to the rotor. Typically achieved through carbon brushes, this step becomes increasingly complex in oil-cooled motor environments – the exact problem Schunk set out to solve.

Current Transmission in Oil-Cooled Motors: The Weak Link

As power density increases in electric motors, so do thermal loads. Many OEMs rely on oil-based cooling systems to manage heat – but traditional current transmission systems are dry-running and must be completely sealed from oil. If seals fail or oil enters the system, it can lead to degraded performance or total failure.

"Our goal was to ensure reliable power transmission even in an oil-filled environment – and to do so over the entire vehicle lifespan," explains Thomas Pichler, Global Account Manager at Schunk Mobility Carbon.

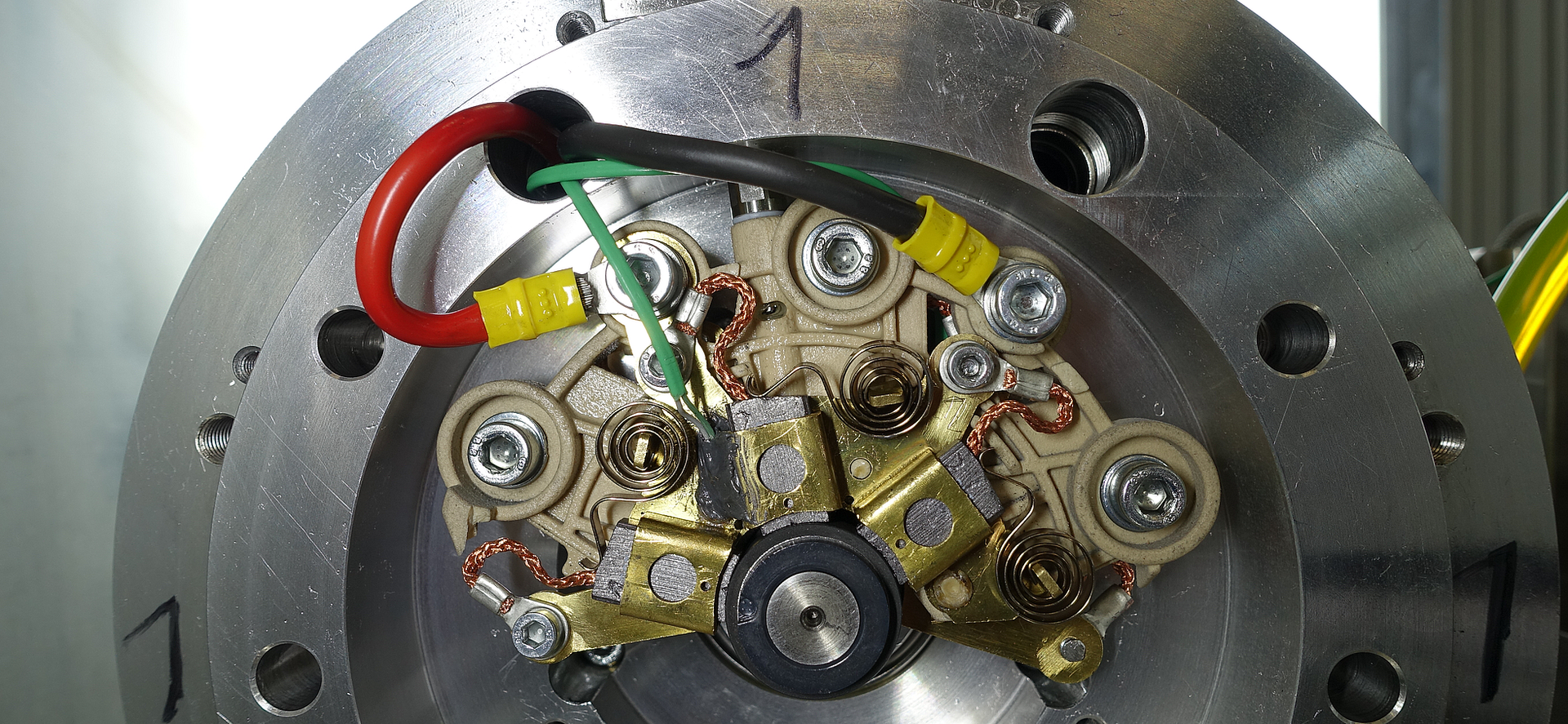

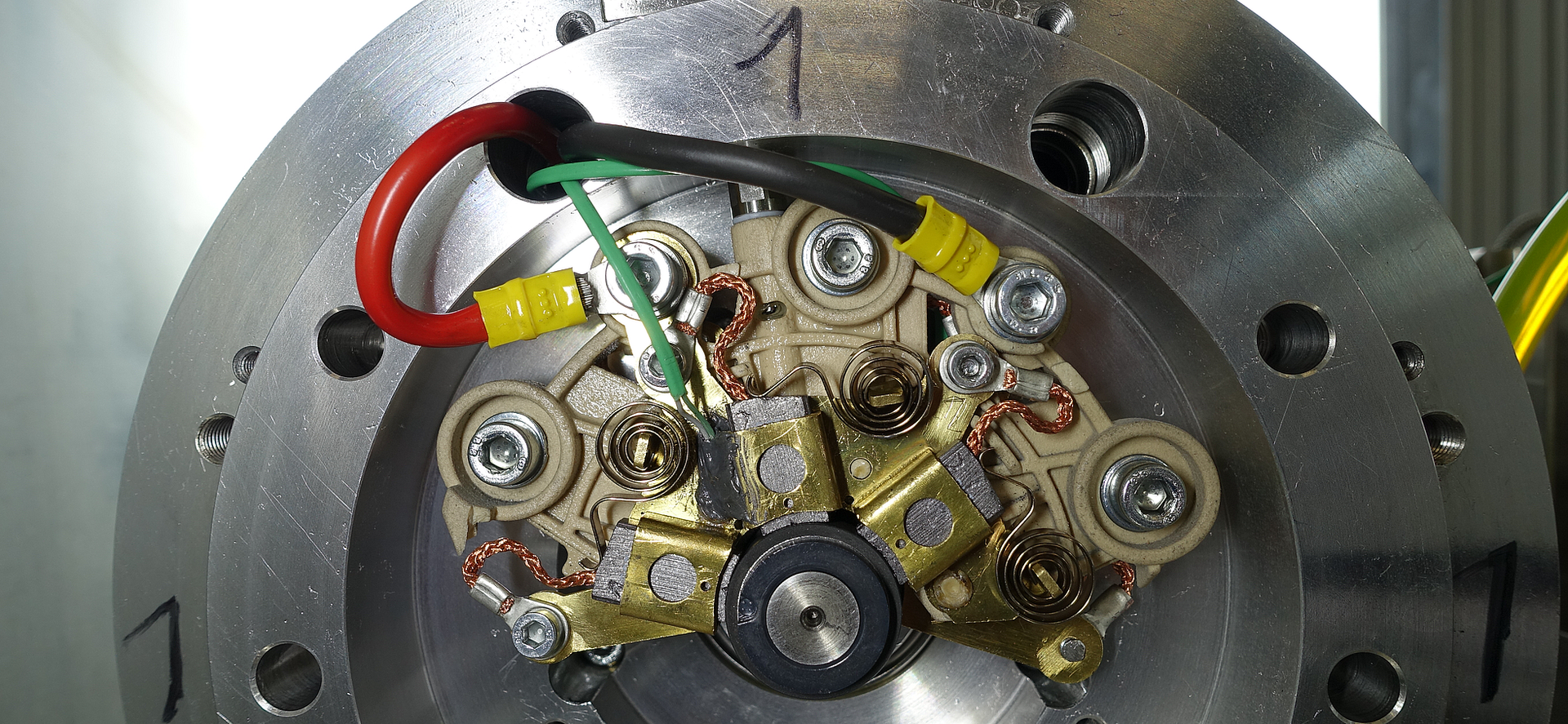

Schunk’s Solution: Wet-Running Slip Ring System for EESMs

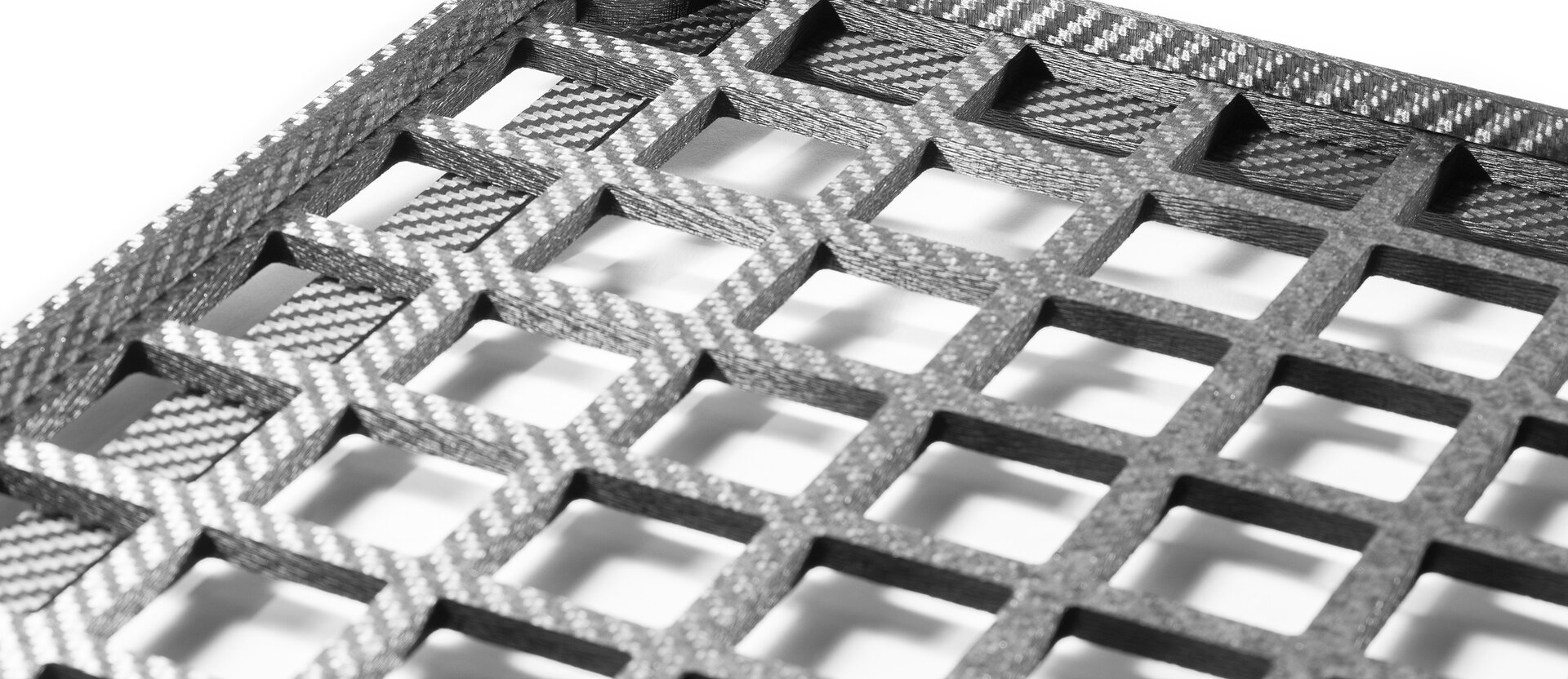

The new system from Schunk consists of a wet-running slip ring and traction module, specifically designed for use in oil-cooled EESMs. Through a custom material composition, the system remains conductive and stable even under harsh operating conditions.

Benefits at a Glance:

“We developed a system that performs where others would fail. That’s a critical enabler for future-proof electric mobility,” says Pichler.

From Prototype to Application: On the Road to Market

The technology was developed at Schunk’s Bad Goisern facility, where a cross-functional team brought it from concept to prototype. Initial samples are already being tested by OEMs, with positive feedback confirming its market potential.

The next step: making the solution commercially viable.

“We know the system works – now we’re focused on scaling it economically,” says Pichler. “Because even the best technical solution needs to make sense commercially.”

Why EESMs Could Define the Next Generation of EVs

Externally Excited Synchronous Motors offer real advantages: no rare earths, lower cost, improved recyclability, and less exposure to global material risks.

With Schunk’s wet-running current transmission, EESMs become even more attractive – offering high efficiency, improved thermal management, and greater resilience under real-world conditions.

Notably, the innovation was selected as a finalist in the Schunk Innovation Contest – reflecting both its technical merit and its strategic relevance for the future of electric drive systems.

Conclusion: A Technological Building Block for Future EVs

Schunk Mobility Carbon’s wet-running current transmission system is more than a materials innovation – it’s a key enabling technology for rare-earth-free, efficient, and robust electric motors. What it means for electric mobility:

The shift to EESMs is coming – and Schunk’s solution is helping drive that transformation.

Interested in learning more? Discover all relevant brochures and technical documents on wet-running power transmission and FSM solutions from Schunk.

Download now!