Pioneering charging solutions for the mobile future

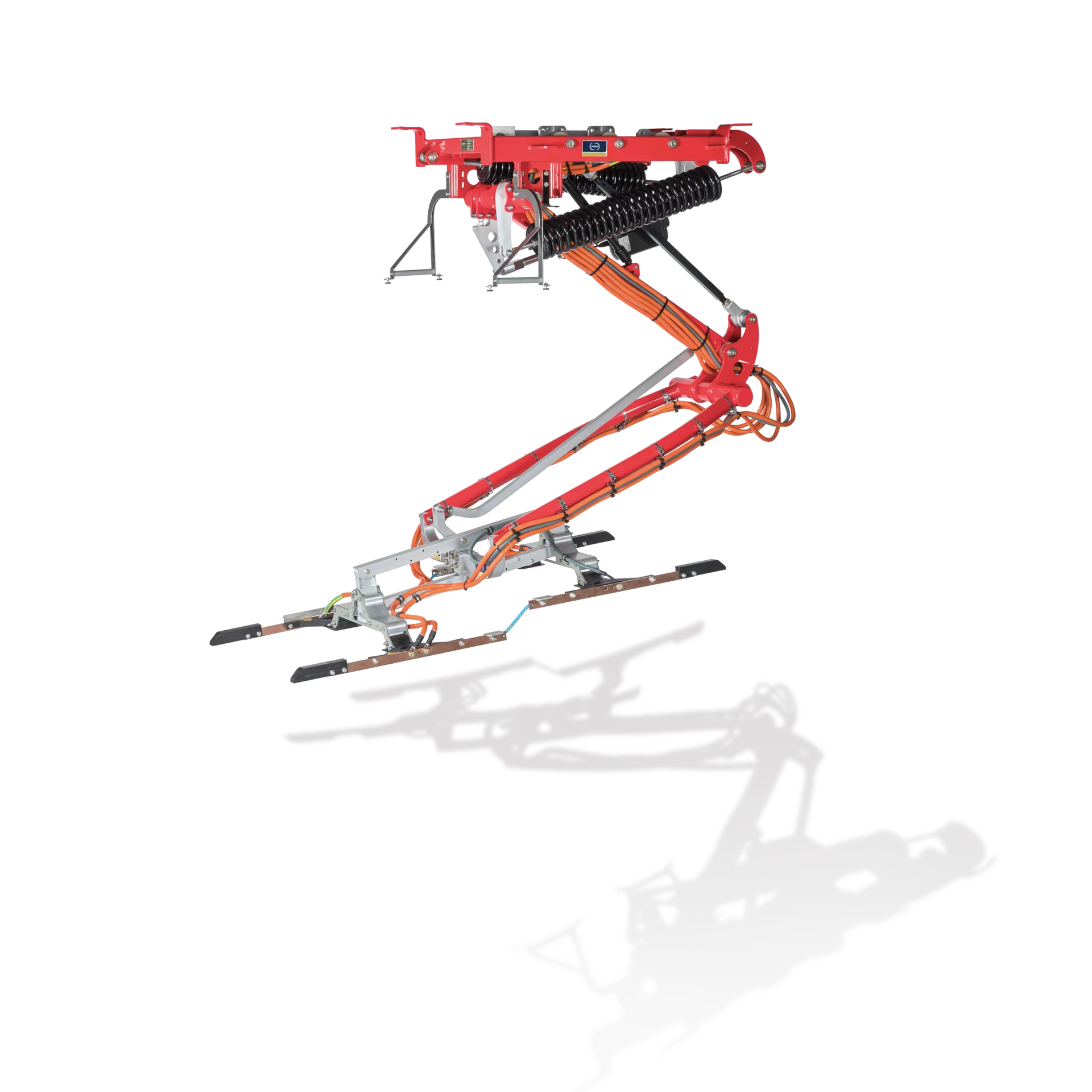

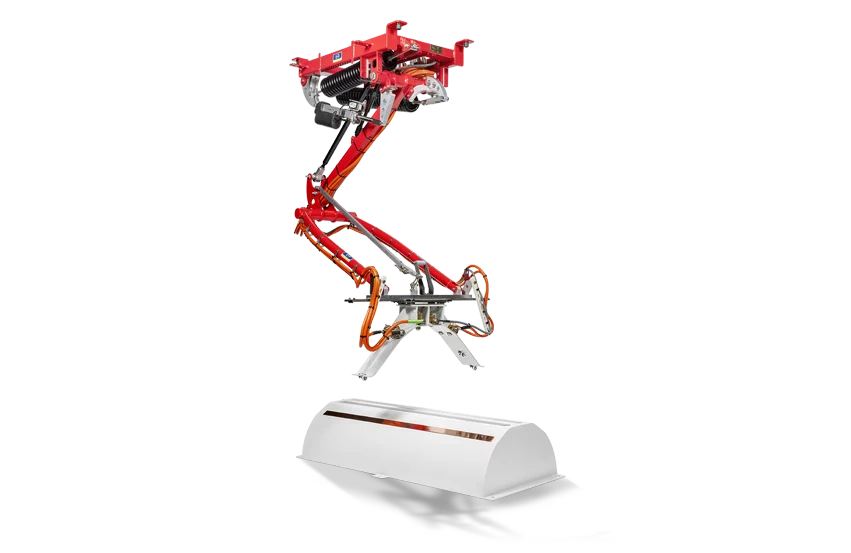

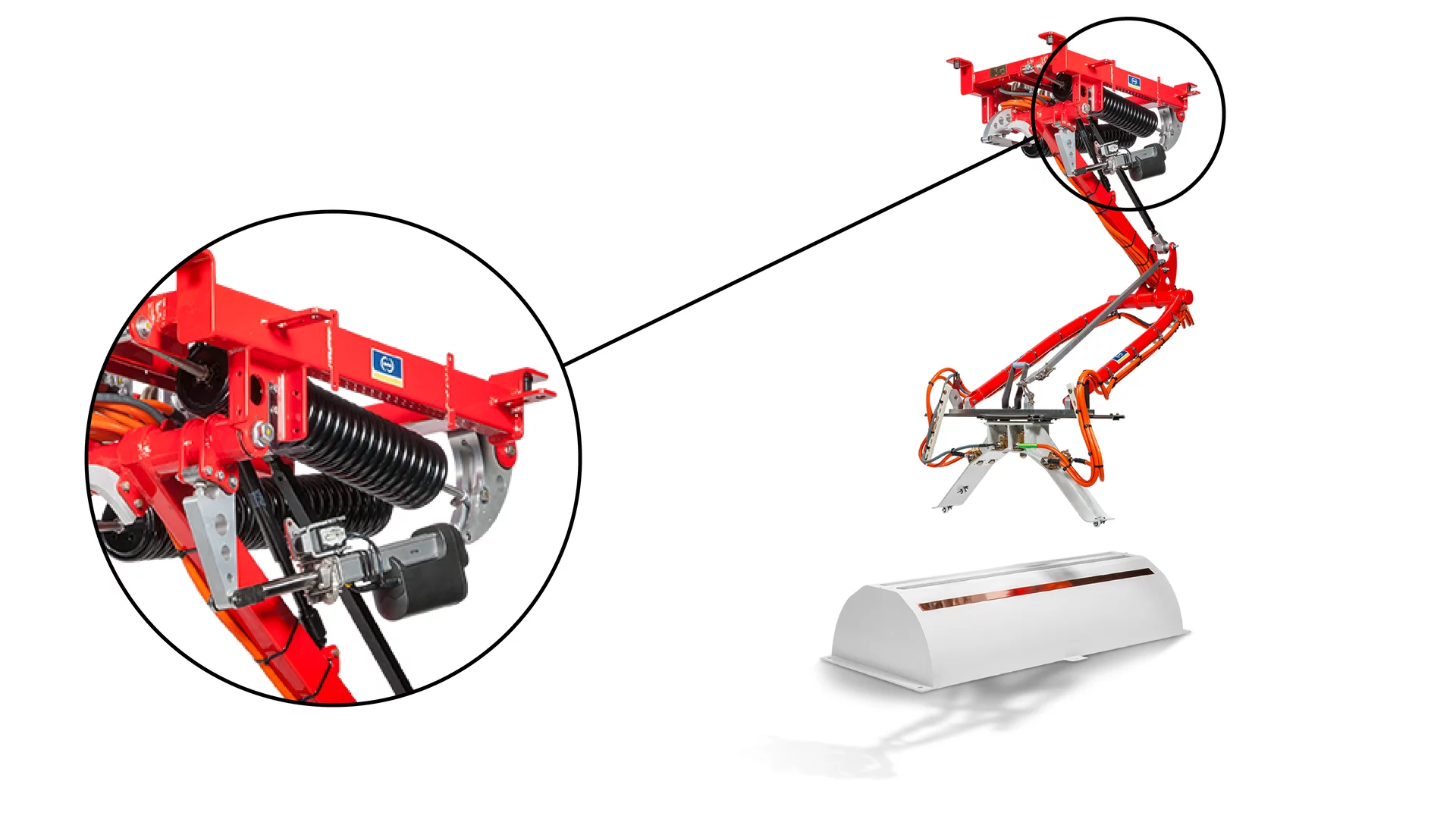

Inverted Pantograph SLS 201

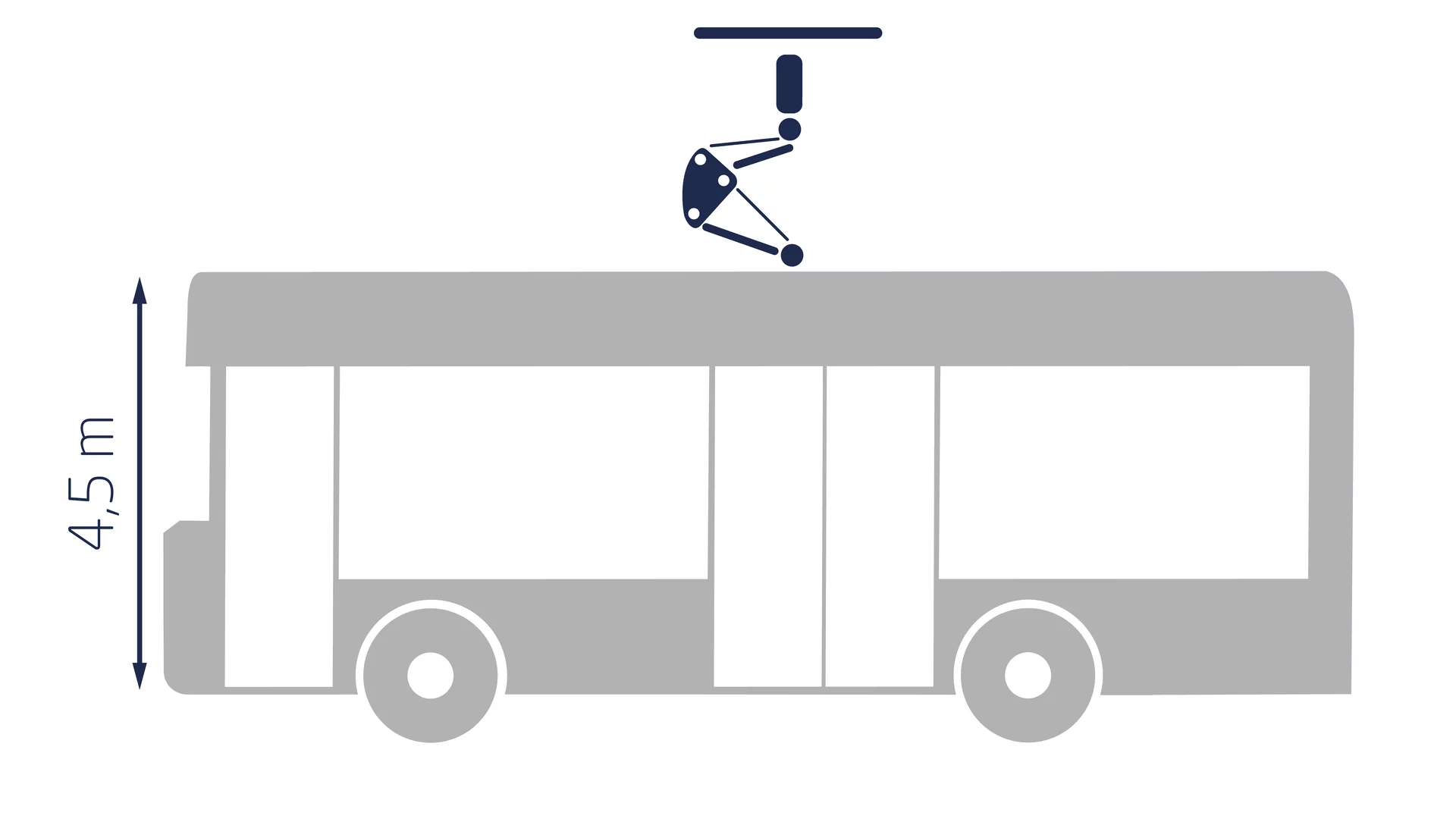

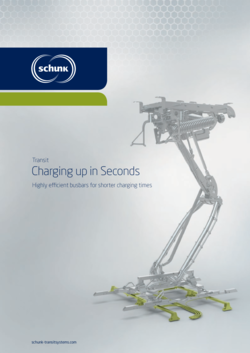

The SLS 201 inverted pantograph is integrated on the infrastructure side at a central location, for example the bus depot or within the route network. Its contacting works according to the top-down principle: The bus parks under the inverted pantograph, which moves down, connects with the counterpart on the bus roof and charges the batteries.

Charging Time: from 30 seconds to overnight charge

Charging Power: up to 600 kW

Set-Up Principle: "Top-Down"

Charging Concept: Opportunity Charging, Flash Charging and Depot Charging

Highly efficient busbars for shorter charging times

100 Cities – 25 Countries: Schunk Smart Charging for Electric Buses is in Use Worldwide

Learn more about the inverted pantograph SLS201.401 from Schunk – the compact solution for reliable current collection in limited space.