Industry Solutions from Schunk Mobility

Learn more about our e-mobility products here

As your e-mobility supplier, we develop pioneering solutions

Around the world, the face of mobility is changing, as it becomes more networked, more efficient and lighter, and more sustainable. As a competent e-mobility supplier, we are on board with this trend right from the start. With innovative e-mobility developments, we are paving the way to a new mobile future for our development partners. Leading manufacturers from the automotive industry and automotive supplier sector trust in our technological expertise. “Schunk inside” stands for safety, quality and reliability – benefits our customers truly appreciate. That is why so many of them trust our company for the long-term. Our components are helping to make modern e-vehicles safer, more efficient, and more environmentally-friendly.

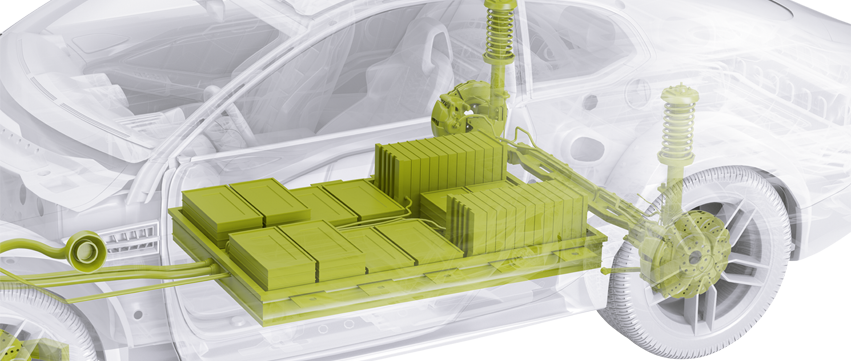

Thermal management, shaft grounding and reinforcement sleeves

Thermal management needs to function reliably, especially when charging and discharging batteries in electric vehicles. The only way to achieve long battery service life is to ensure top-notch thermal performance. Thermal runaway protection concepts for Li-ion batteries are also necessary - in an area where everything is constantly getting smaller, lighter and more powerful.

The challenge in shaft grounding is ensuring reliable function, even if components are in the oil circulation system. Customers expect systems to reliably dissipate disturbances up to the 100 MHz range and easily integrate into existing design concepts, without requiring significant structural changes to the engine. Installation requirements also play a major role in designing our reinforcement sleeves. These are used to stabilize high-speed rotors, for example inside an e-turbo. We are happy to help you select the right materials for your specific application and determine the correct installation for your sleeves if desired.

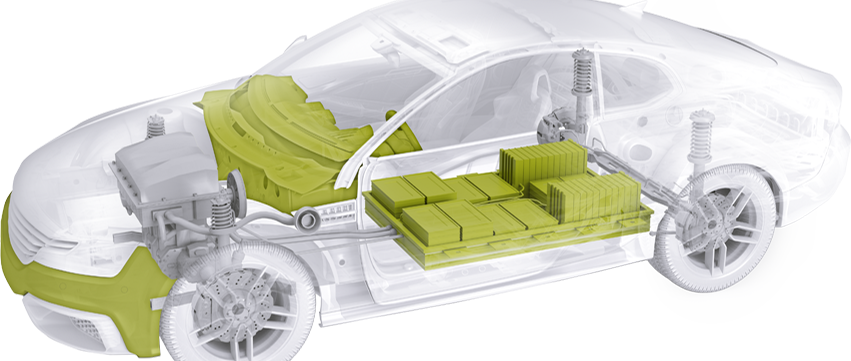

Soft magnetic components from Schunk as e-mobility supplier

Soft magnetic components also play key functions in the axial flow engine of the electric drivetrain. These components need to be suitable for manufacturing efficiently in large-scale series production, need to delivery high power and torque density, and take up as little space as possible. We can react flexibly to all of these requirements – thanks to our many years of supplier experience and extensive materials expertise.

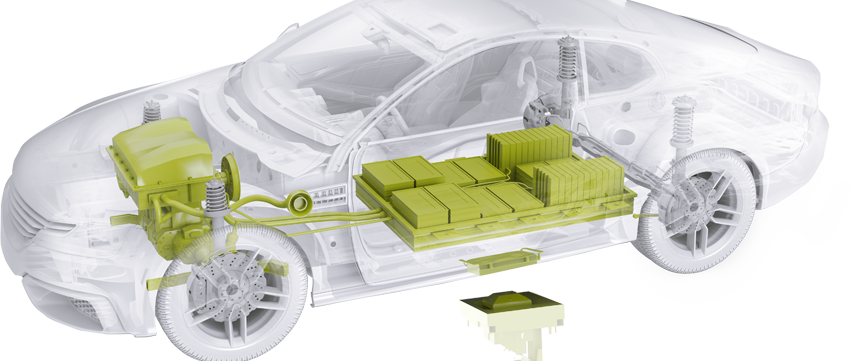

Sintered metals play a key role in e-mobility

Just as in conventional vehicle manufacturing, our solutions made of specialized sintered metals are used worldwide in electric vehicles as well. Our functional components are used in many different applications, for instance when actuators are used to convert electric signals into movement. In addition, our self-lubricating and high-precision sintered bearings ensure smooth function in electric drives. Our components are also installed in coolant pumps.

Advantages of using Schunk as your e-mobility supplier

When you work with Schunk, you will have a partner you can always expect more from – including from our range of high-quality components for e-mobility. Our shaft grounding and thermal management components, for instance, extend the service lives of electric engines and batteries – with guaranteed functionality throughout the entire vehicle life. Rely on customer-specific material options and designs individually tailored to specific thermal requirements. If you use a stray current transmitter (SCT), our current transmitter system will likewise be a great choice to meet your needs.

Furthermore, we develop our reinforcement sleeves for you with high-precision manufacturing from customized materials for improved performance – these sleeves are used, for instance in e-turbo technology. In addition, powder metallurgy has become the established standard process for reliable large-scale series production of magnetically soft components. Due to the greater design freedom (isotropic material properties), they can be used to create more complex engine topologies, such as axial and transverse flow engines – with excellent resource efficiency and minimum eddy current loss.

Do you have any questions about our Solutions for E-Mobility?